A plastic hydraulic oil tank anti-oil return impact rotational molding

A technology of rotomolding and hydraulic oil tanks, which is applied in the direction of oil supply tank devices and mechanical equipment, can solve problems such as leakage of atmospheric pressure interfaces, reduce oil return pressure, prolong service life, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

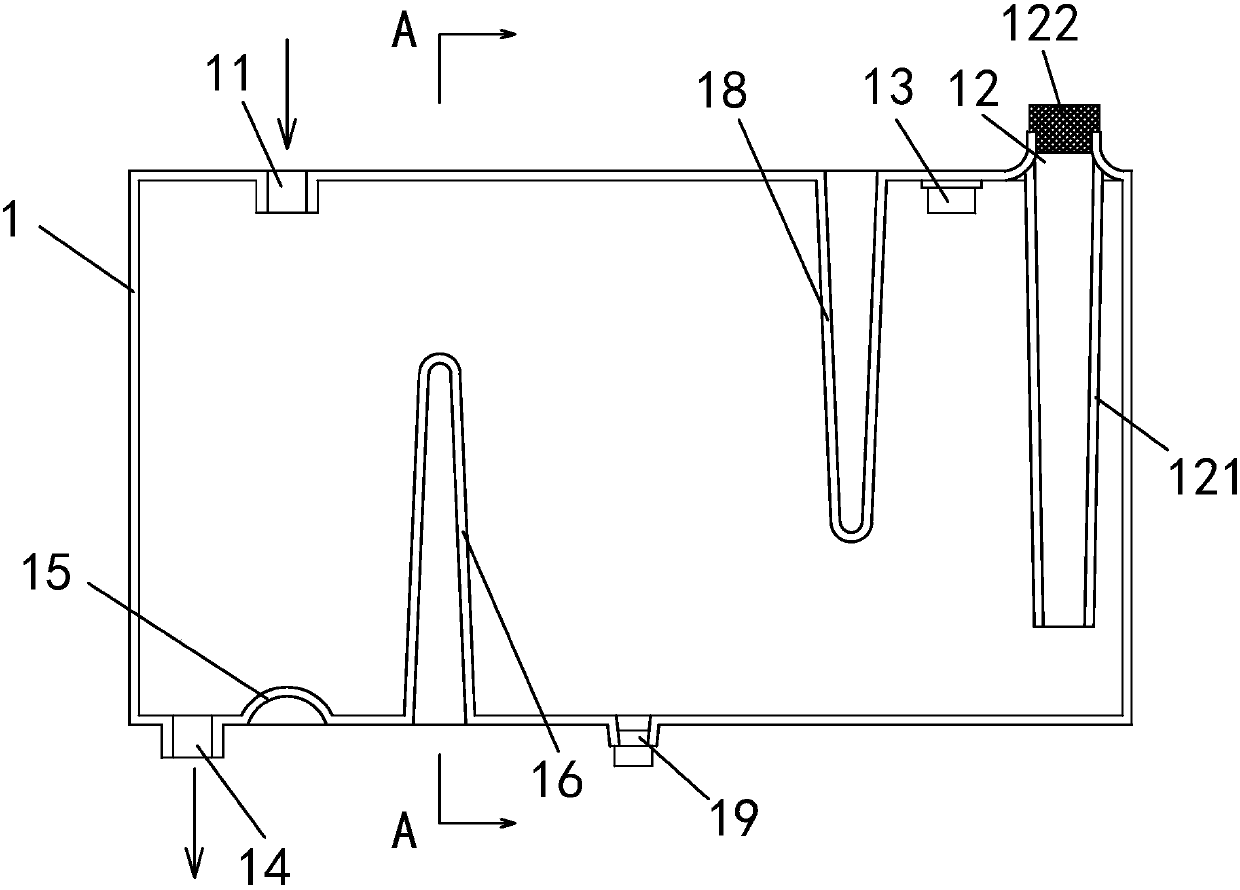

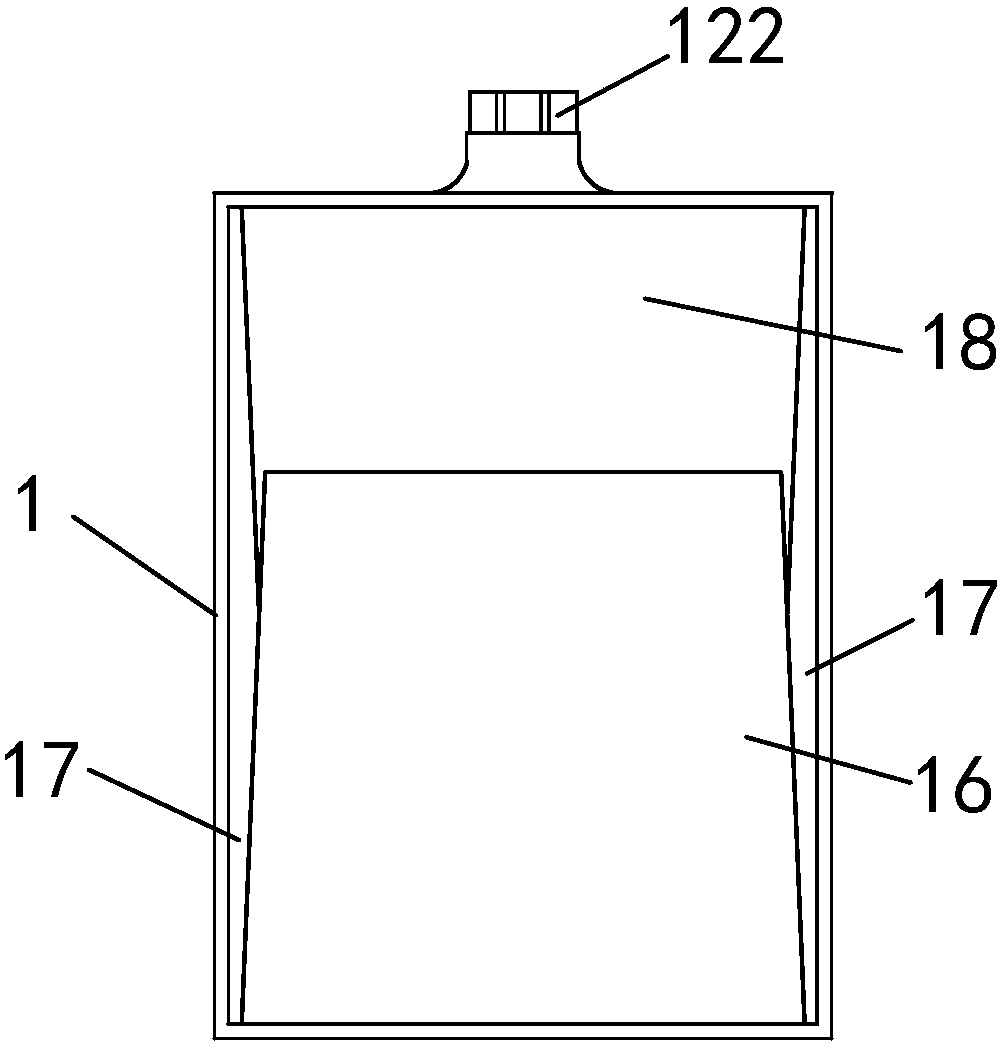

[0017] Example: see Figure 1-2 Shown:

[0018] A plastic hydraulic oil tank anti-oil return impact rotomoulding, comprising a box body 1, the top of the box body 1 is provided with an oil return port 11, a fuel port 12 and an exhaust port 13, and the bottom of the box body 1 is provided with an oil outlet port 14. The fuel filler cap is provided with a fuel tank cap 122 .

[0019] see figure 1 As shown, the oil return port 12 is opened on one end of the top wall of the box body 1, and the exhaust port 13 and the oil filling port 12 are provided at the other end of the box body 1, and the bottom wall of the box body 1 A buffer boss 15 is arranged on the inner surface, and the oil return port 11 is opposite to the buffer boss 15 up and down.

[0020] and, see figure 1 As shown, the inside of the box body 1 is provided with a lower baffle plate 16 on the side of one end of the buffer boss 15 toward the box body 1 where the exhaust port 13 and the oil filler port 11 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com