Automotive OEM (original equipment manufacturer) intermediate coat with high solid content and low viscosity and preparation method of intermediate coat

A low-viscosity, high-solids technology, applied in the field of coatings, can solve the problems of narrow application range of powder coatings and PVC coatings, large increase in raw material costs, and insufficient appearance and development, and achieve superior environmental performance, good interlayer adhesion, The effect of small molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

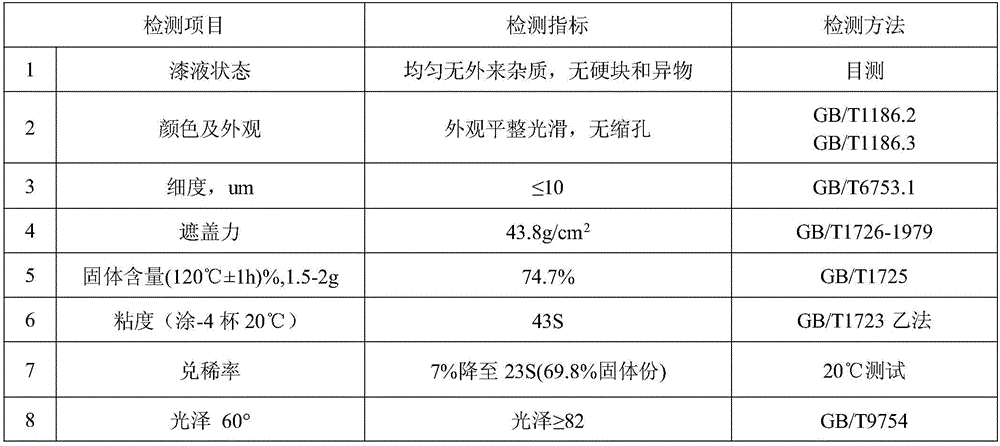

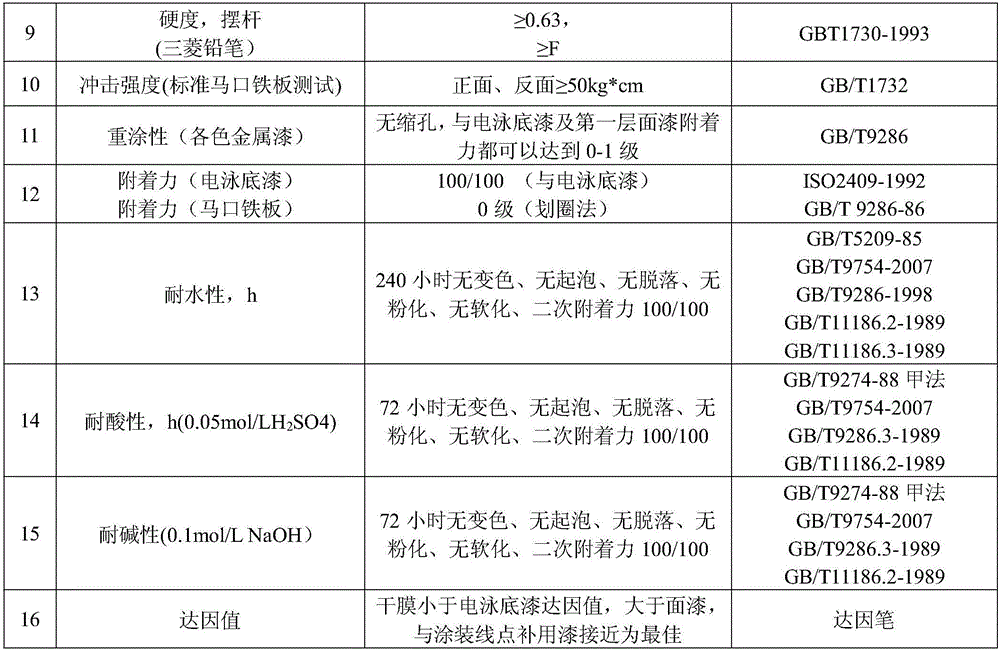

Embodiment 1

[0032] A high-solid-content low-viscosity automotive OEM intermediate coating. The raw materials are composed of 25% polyester resin, 12% anti-sagging resin, 20% rutile titanium dioxide, and 12% ultra-fine precipitated barium sulfate. Dispersant 1%, white carbon black 0.3%, silicone leveling agent 0.3%, acrylate leveling agent 0.6%, surfactant 0.4%, anti-settling agent 0.2%, cyclohexanone 3%, ethylene glycol ether acetate 3% ester, 0.2% carbon black, 20% butylated amino resin, 2% partially methylated amino resin.

[0033] The polyester resin, in parts by weight, consists of raw materials: 2.0 parts of isooctanoic acid, 20 parts of adipic acid, 5 parts of tetrahydrophthalic anhydride, 16 parts of phthalic anhydride, and 1 part of trimethylpentanediol , 30 parts of neopentyl glycol, 7 parts of pentaerythritol, 0.3 parts of hypophosphorous acid, 0.05 parts of antioxidant 1010, 15 parts of dimethyl mixed acid, 2.0 parts of xylene, 3 parts of propylene glycol methyl ether acetate, ...

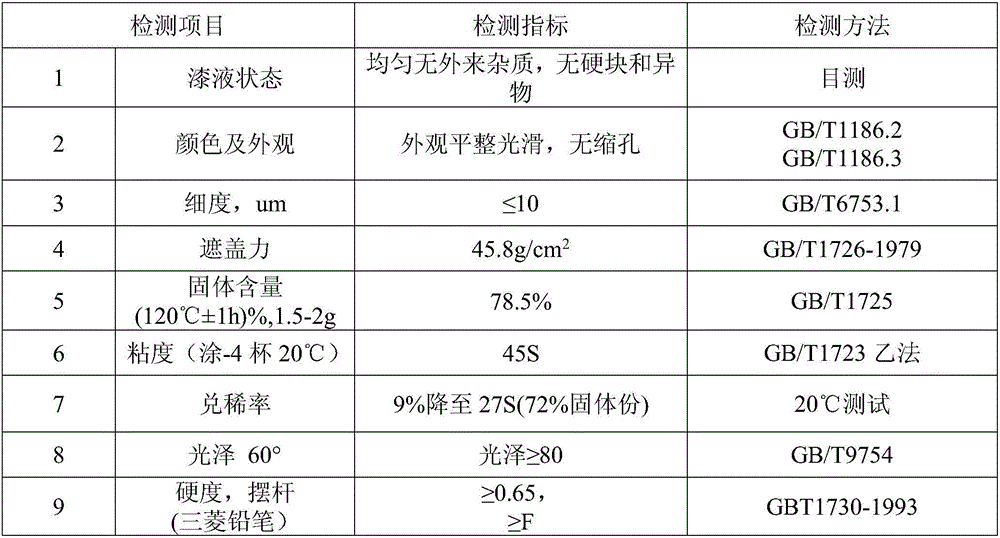

Embodiment 2

[0052] A high-solid-content low-viscosity automotive OEM intermediate coating. The raw materials are composed of 30% polyester resin, 10% anti-sagging resin, 15% rutile titanium dioxide, 1% glass hollow microspheres, and super Fine precipitated barium sulfate 12%, dispersant 1%, white carbon black 0.15%, silicone leveling agent 0.3%, acrylate leveling agent 0.3%, surfactant 0.2%, ethylene glycol ether acetate 5%, carbon Black 0.05%, butylated amino resin 23%, partially methylated amino resin 2%.

[0053] Described polyester resin, by weight, its raw material is composed of: 1.5 parts of benzoic acid, 1.5 parts of isooctanoic acid, 28 parts of adipic acid, 10 parts of phthalic anhydride, 2 parts of trimethylpentanediol, 25 parts of neopentyl glycol, 4 parts of pentaerythritol, 0.1 part of antioxidant 1010, 5 parts of dimethyl mixed acid, 1 part of xylene, 6 parts of propylene glycol methyl ether acetate, and 5 parts of butyl acetate.

[0054] The anti-sagging resin is made of ...

Embodiment 3

[0072] A high-solid-content low-viscosity automotive OEM intermediate coating, in terms of mass percentage, its raw materials are: 35% polyester resin, 5% anti-sag resin, 15% rutile titanium dioxide, 2% glass hollow microspheres, super Fine precipitated barium sulfate 15%, dispersant 2%, white carbon black 0.1%, silicone leveling agent 0.1%, acrylate leveling agent 0.3%, surfactant 0.45%, ethylene glycol ether acetate 3%, carbon Black 0.05%, butylated amino resin 20%, partially methylated amino resin 2%.

[0073] The polyester resin, in parts by weight, consists of raw materials: 0.5 parts of benzoic acid, 1 part of isooctanoic acid, 24 parts of adipic acid, 2.5 parts of tetrahydrophthalic anhydride, 13 parts of phthalic anhydride, trimethyl 0 parts of pentylene glycol, 35 parts of neopentyl glycol, 5 parts of pentaerythritol, 0.2 parts of hypophosphorous acid, 10 parts of dimethyl mixed acids, 0.5 parts of xylene, 4 parts of propylene glycol methyl ether acetate, and 3 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com