Air conditioner fin cleaning agent and preparation method thereof

A technology for air-conditioning fins and cleaning agents, which is applied in the direction of inorganic non-surface-active cleaning compositions, etc., can solve the problems of decay, brittle aluminum fins, loss of heat dissipation function of equipment, etc., and achieves good energy-saving effect, remarkable energy-saving effect, Overcome the effect of being susceptible to corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

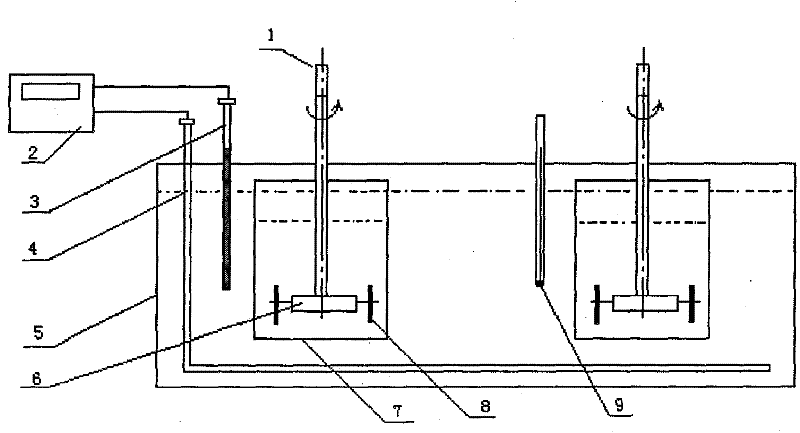

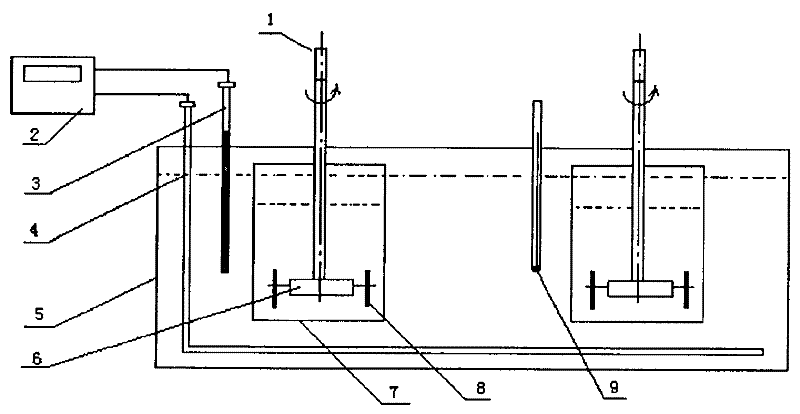

Image

Examples

Embodiment 1

[0035] The air conditioner fin cleaning agent is made of the following components in weight percentage: 10kg of nitric acid, 0.5kg of potassium chromate, 0.5kg of AES, 50.1kg of OP-50.1kg, and 88.9kg of water.

[0036] Preparation:

[0037] a. Take half of the amount of water, add nitric acid while stirring at room temperature, and then stir for 3 minutes after adding, to obtain aqueous solution a;

[0038] b. Take the other half of the water, heat it to 50°C, add potassium chromate, AES, OP-10 in turn, stir well until the solid particles are completely dissolved, then cool it to room temperature to obtain the aqueous solution b.

[0039] c. Slowly add the uniformly stirred aqueous solution a into the aqueous solution b, stir thoroughly for 3 minutes until uniform, and the finished product is prepared.

Embodiment 2

[0041] The cleaning agent for air conditioner fins is made from the following components in percentage by weight: 13kg of nitric acid, 0.6kg of potassium chromate, 0.7kg of AES, 60.3kg of OP-6, and 85.4kg of water.

[0042] Preparation method: the stirring time in step a is 4 min; the heating temperature in step b is 55° C.; the stirring time in step c is 4 min; the others are the same as in Example 1.

Embodiment 3

[0044] The air conditioner fin cleaning agent is made of the following components in weight percentage: 15kg of nitric acid, 0.8kg of potassium chromate, 0.8kg of AES, 70.5kg of OP-70.5kg, and 82.9kg of water.

[0045] Preparation method: the stirring time in step a is 5 min; the heating temperature in step b is 60° C.; the stirring time in step c is 5 min; the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| descaling rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com