Device for removing oil on surface of belt material

A strip surface, air purging device technology, applied in the workpiece surface treatment equipment, cleaning methods and appliances, metal rolling and other directions, can solve the problem of inability to remove the strip lubricating fluid, and achieve safe and reliable degreasing performance. , The effect of low loss and fast oil removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

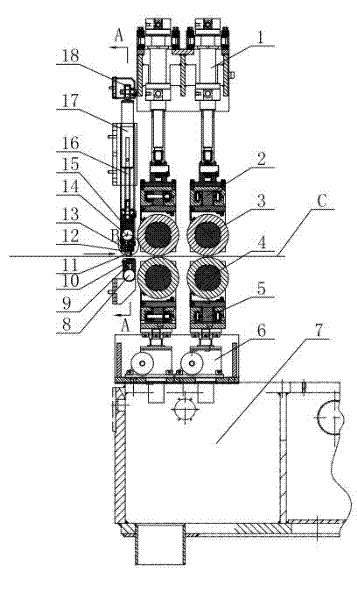

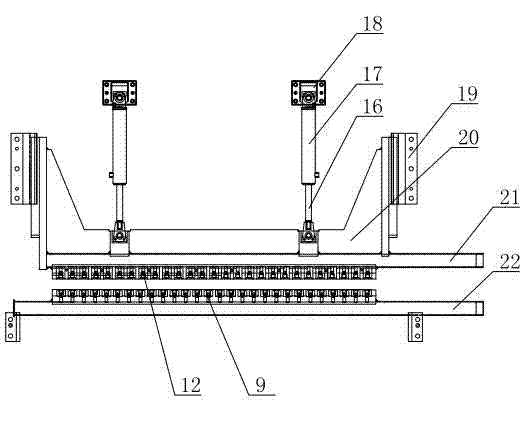

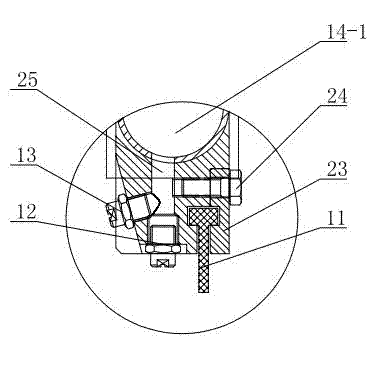

[0022] Such as figure 1 and figure 2 As shown, the present invention includes a support 7, a nozzle mechanism, a scraper mechanism, a rubber roller mechanism and an air purging device;

[0023] The structure of the rubber roller mechanism is as follows: it includes an upper rubber roller 3 and a lower rubber roller 4, the upper rubber roller 3 and the lower rubber roller 4 are installed on the rubber roller mounting seat 2 and the rubber roller mounting seat 5 respectively, and the rubber roller of the upper rubber roller 3 The roller mounting seat 2 is installed on the end of the piston rod of the oil cylinder 1, the rubber roller mounting seat 5 of the lower rubber roller 4 is connected with the screw lifting device 6, and the screw lifting device 6 is connected with the machine base 7, and the function of the screw lifting device 6 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com