Copper strip electrochemical oil removal method in clad-welding method copper-clad aluminum wire production line and device thereof

A technology for clad welding and copper clad aluminum wire, applied in the field of electrochemical degreasing method and devices used, can solve the problems of small degreasing effect, short operation time of copper strip, discoloration of copper strip surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

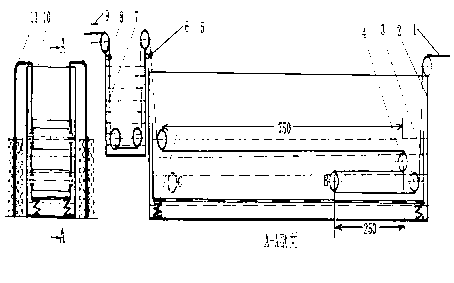

[0016] Schematic diagram of the copper strip electrochemical degreasing device figure 1 shown. Among the figure 2 is the degreasing tank formed by plastic welding. Groove size: length 1000mm, width 100mm, height 200mm. Put a certain depth of degreasing agent in the tank.

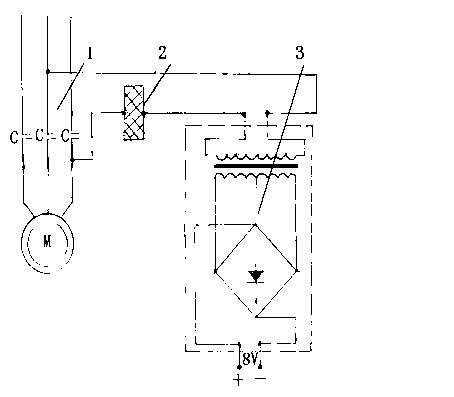

[0017] There is also an 8V rectified power supply ( figure 1 not shown in ). Its negative pole (-) is in contact with the running copper belt through the roller, and the positive pole (+) is placed in the degreasing tank through the electrode plate.

[0018] Such as figure 2 As shown, the solenoid coil 2 (ie figure 1 10) and the primary stage of the rectified power supply 3 are all connected to the power line of the main motor M of the production line. When the contactor C is connected and the production line is running, the electromagnet coil 2 is energized and the armature is sucked down. From figure 1 It can be seen that now the armature drives the lever 11 to press the transmission case down in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com