Method for preparing hydroxide anionic water used for removing greasy dirt, cleaning, sterilizing and disinfecting

A negative ion water, sterilization and disinfection technology, applied in the direction of botany equipment and methods, disinfectants, chemical instruments and methods, etc., can solve the problems of natural environment pollution, endocrine disorders, side effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0018] The method for preparing the hydroxide anion water for degreasing, cleaning and sterilizing according to the present invention is carried out based on the following device.

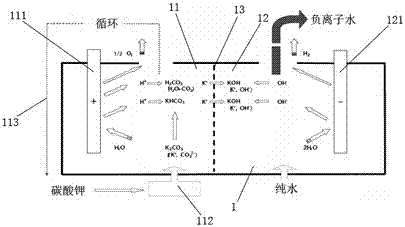

[0019] that is, figure 1 As shown, prepare a case body 1, this case body 1 is divided into cathode electrode case 12 and anode electrode case 11 by the cationic resin membrane 13 that is arranged in the case body 1, the cationic resin film 13 that selects here has the ability to block large Part of the potassium ions move, and only a small amount of potassium ions can pass through the cationic resin membrane 13 to form an electrolytic current.

[0020] An anode electrode 111 is inserted in the anode electrode box 11, and a pure water electrolyte containing potassium carbonate catalyst is circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com