Phosphorus-free degreasing powder, production process and phosphorus-free degreasing process thereof

A production process, oil powder technology, applied in the production process and non-phosphorus degreasing process, the field of non-phosphorus degreasing powder, can solve the problems that restrict the large-scale application of non-phosphorus degreasing powder, high working concentration, slow degreasing speed, etc. , to achieve the effect of excellent cleaning effect, low concentration and fast degreasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

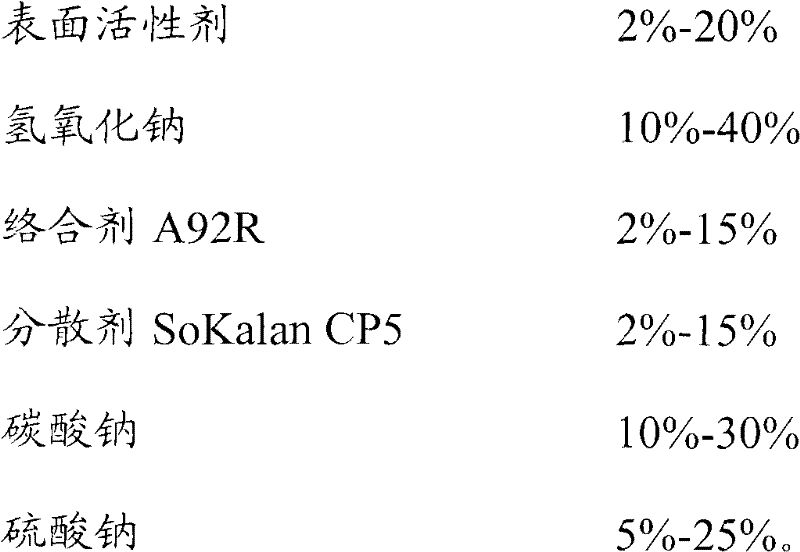

[0045] Prepare non-phosphorus degreasing powder according to the production process of the present invention, and the composition of non-phosphorus degreasing powder is as shown in table 1:

[0046] Table 1. Composition of phosphorus-free degreasing powder

[0047] raw material

Mass percentage (%)

Compound Surfactant

20

30

Complexing agent A92R

2

Builder SoKalan CP5

10

20

18

[0048] The compounded surfactant is obtained by compounding 60wt% of nonionic surfactant, 30wt% of anionic surfactant, 5wt% of penetrating agent and 5wt% of wetting agent.

[0049] The non-phosphorous degreasing process of non-phosphorus degreasing powder, it comprises the following steps:

[0050] (1) Prepare a degreasing liquid with a concentration of 40g / L from phosphorus-free degreasing powder and water, and add it to a PVC cleaning tank. The pH of the d...

Embodiment 2

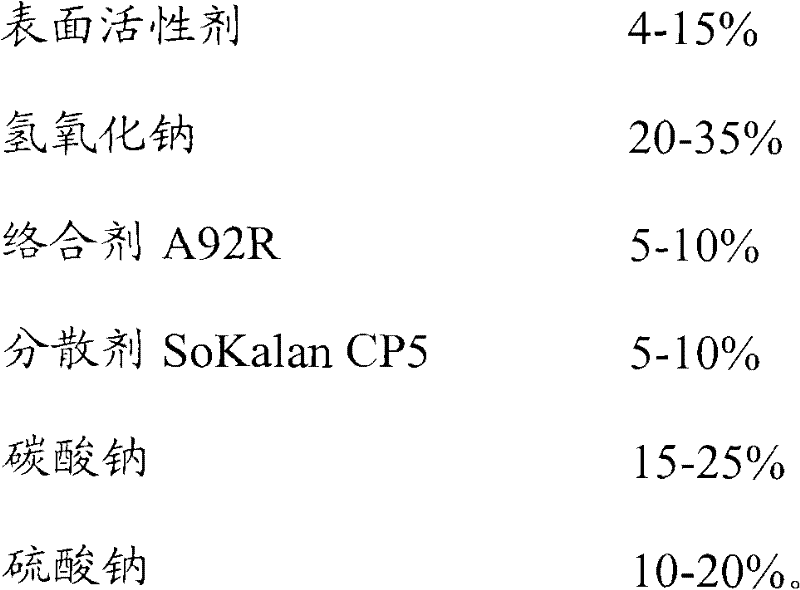

[0054] Prepare non-phosphorus degreasing powder according to the production process of the present invention, and the composition of non-phosphorus degreasing powder is as shown in table 2:

[0055] Table 2. Composition of phosphorus-free degreasing powder

[0056] raw material

Mass percentage (100%)

Surfactant

12

10

Complexing agent A92R

8

Builder SoKalan CP5

15

30

25

[0057] The non-phosphorous degreasing process of non-phosphorus degreasing powder, it comprises the following steps:

[0058] (1) Prepare a degreasing liquid with a concentration of 50g / L by mixing phosphorus-free degreasing powder and water, add it to the PVC cleaning tank, adjust the pH of the degreasing liquid to 10, use stainless steel tubes to heat, and adjust the temperature of the degreasing liquid is 90°C.

[0059] (2) Soak and clean the workpiece in the...

Embodiment 3

[0062] Prepare non-phosphorus degreasing powder according to production process of the present invention, and the composition of non-phosphorus degreasing powder is as shown in table 3:

[0063] Table 3. Composition of phosphorus-free degreasing powder

[0064] raw material

mass percentage

Surfactant

15

25

Complexing agent A92R

10

Builder SoKalan CP5

10

Sodium carbonate

25

15

[0065] The non-phosphorous degreasing process of non-phosphorus degreasing powder, it comprises the following steps:

[0066] (1) Prepare a degreasing liquid with a concentration of 60g / L by mixing phosphorus-free degreasing powder and water, add it to the PVC cleaning tank, adjust the pH of the degreasing liquid to 8.8, use stainless steel tubes to heat, and adjust the temperature of the degreasing liquid is 45°C.

[0067] (2) Soak and clean the workpiece in the degreasi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com