Special metal cleaning agent for water-based reactive aluminum product and preparation method thereof

A metal cleaning agent and reactive technology, applied in the field of metal cleaning agents, can solve the problems of low corrosion rate and corrosion of aluminum products, and achieve the effects of low cleaning cost, fast degreasing speed, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

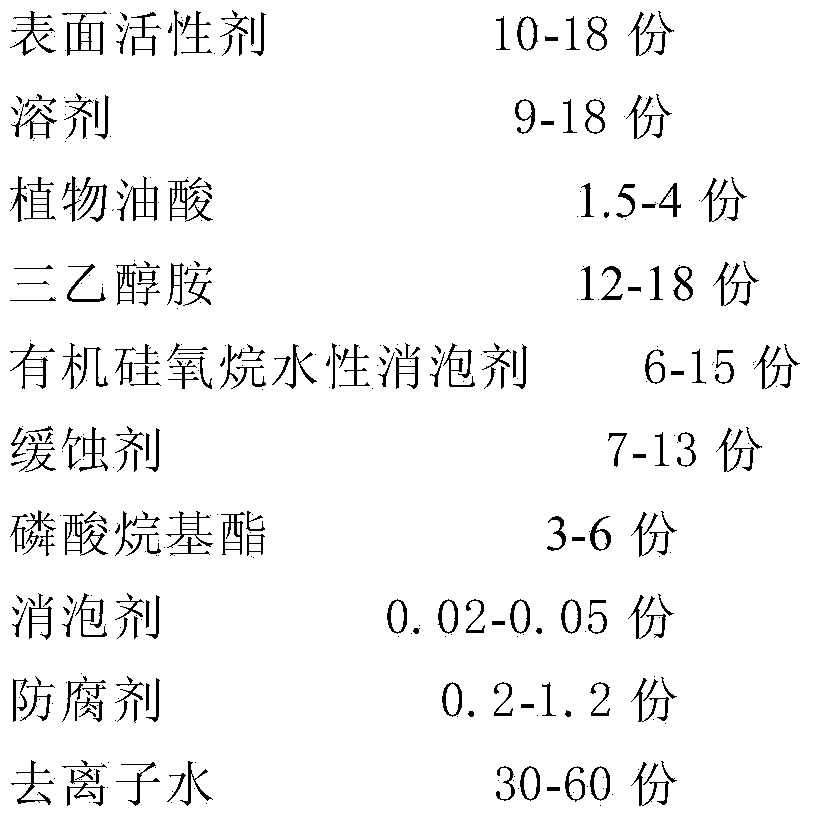

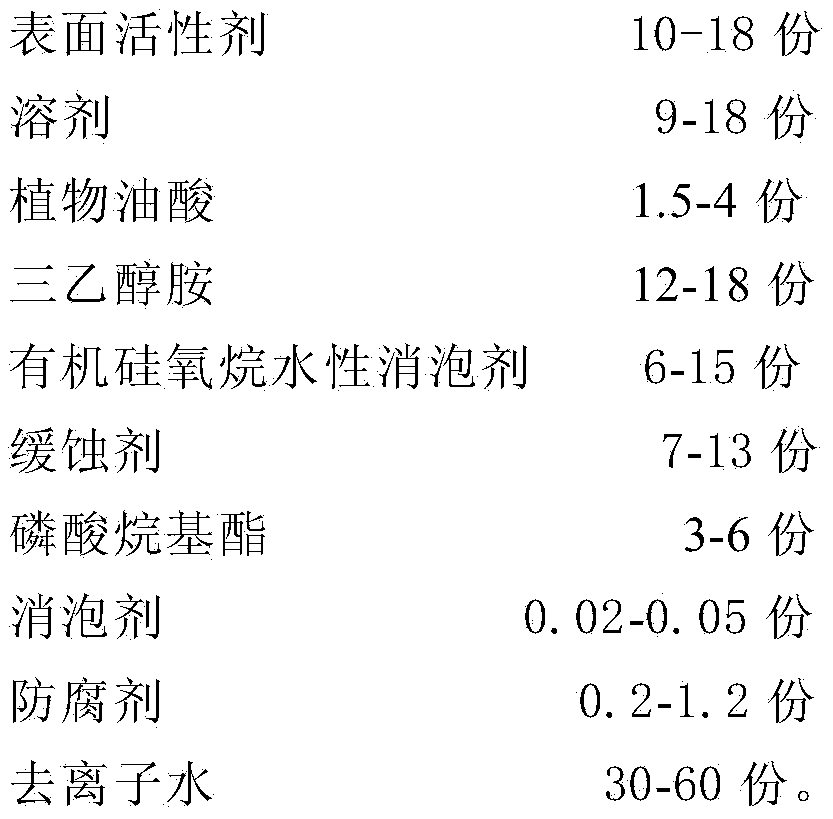

Embodiment 1

[0036] A special metal cleaning agent for water-based reactive aluminum. Its composition and weight (kg) are: Surfactant 10 [where L644; APG08104; FMEE2]; Solvent 9 (where D605; isopropanol 2; two Ethylene glycol butyl ether 2); vegetable oleic acid 1.5; triethanolamine 12; organosiloxane 6 (including MS4552; MS5252; MS5502); corrosion inhibitor 7 (including borate 5; sodium silicate 2); phosphate alkyl Ester 3; Defoamer 0.02; Preservative 0.2; Deionized water 30.

[0037] The preparation method of the water-based reaction type aluminum special metal cleaning agent, the preparation method steps are:

[0038] 1. Add 30 kg of deionized water to the reaction flask equipped with reflux condenser, stirrer, thermometer and addition funnel, heat up to 65℃, add 644 kg of L, APG08102 kg, and 2 kg of FMEE, heat up to 75℃, and stir for 10 minutes , To make a variety of surfactants fully mixed.

[0039] 2. Add D605 kg, 2 kg isopropanol, 2 kg diethylene glycol butyl ether to the above mixture, ...

Embodiment 2

[0045] A water-based reactive aluminum metal cleaning agent, its composition and weight (kg) are: surfactant 18 [where L648; APG08107; FMEE3]; solvent 18 (where D608; isopropanol 5; two Ethylene glycol butyl ether 5); vegetable oleic acid 4; triethanolamine 18; organosiloxane 15 (including MS4555; MS5255; MS5505); corrosion inhibitor 13 (including borate 8; sodium silicate 5); phosphate alkyl Ester 6; Defoamer 0.05; Preservative 1.2; Deionized water 60.

[0046] The preparation method of the water-based reaction type aluminum special metal cleaning agent, the preparation method steps are:

[0047] 1. Add 60 kg of deionized water to a reaction flask equipped with reflux condenser, stirrer, thermometer and addition funnel, heat up to 65°C, add 648 kg of L, APG08107 kg, and 3 kg of FMEE, heat up to 75°C, and stir for 10 minutes , To make a variety of surfactants fully mixed.

[0048] 2. Add D608 kg, isopropanol 5 kg, and diethylene glycol butyl ether 5 kg to the above mixture. Heat to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com