Rapid deoiling device for rare earth feed liquid

A rare earth material liquid, fast technology, applied in the direction of process efficiency improvement, etc., can solve the problem of rare earth material liquid degreasing, etc., to achieve the effect of complete degreasing and precise rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

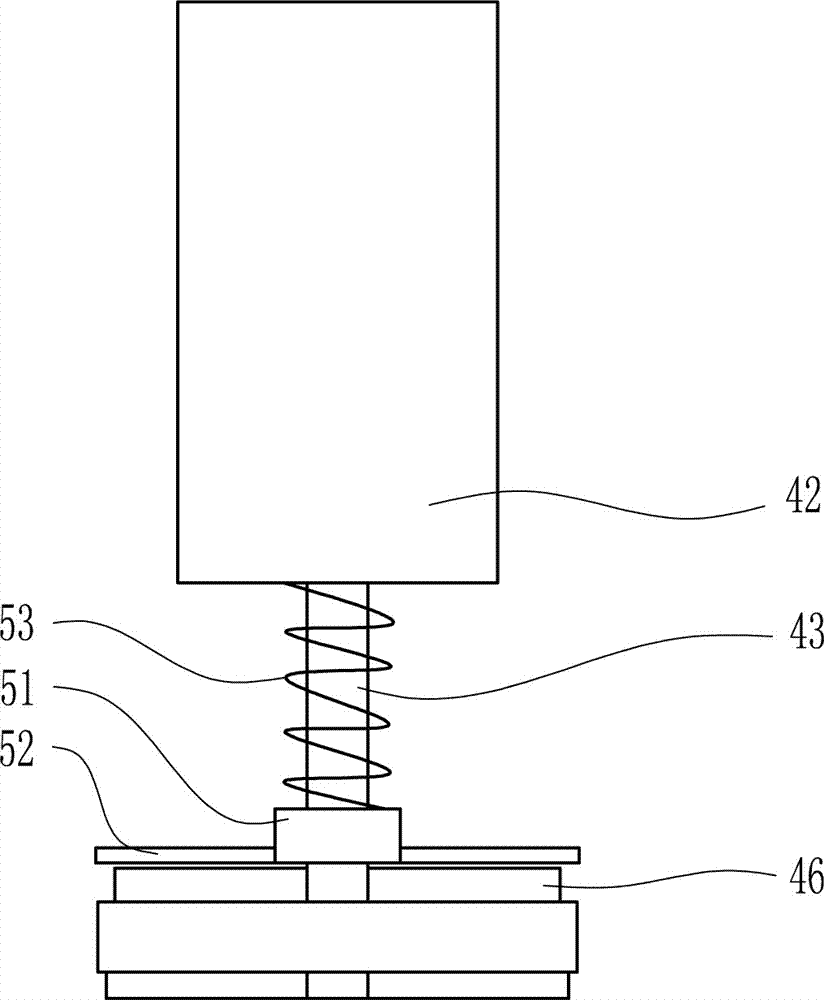

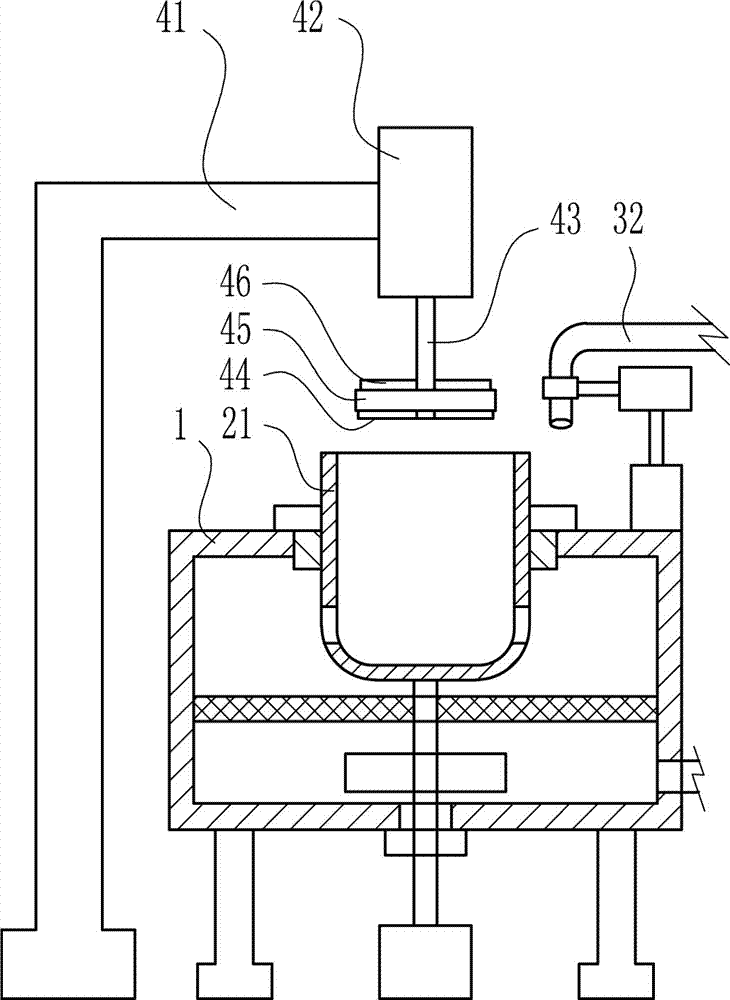

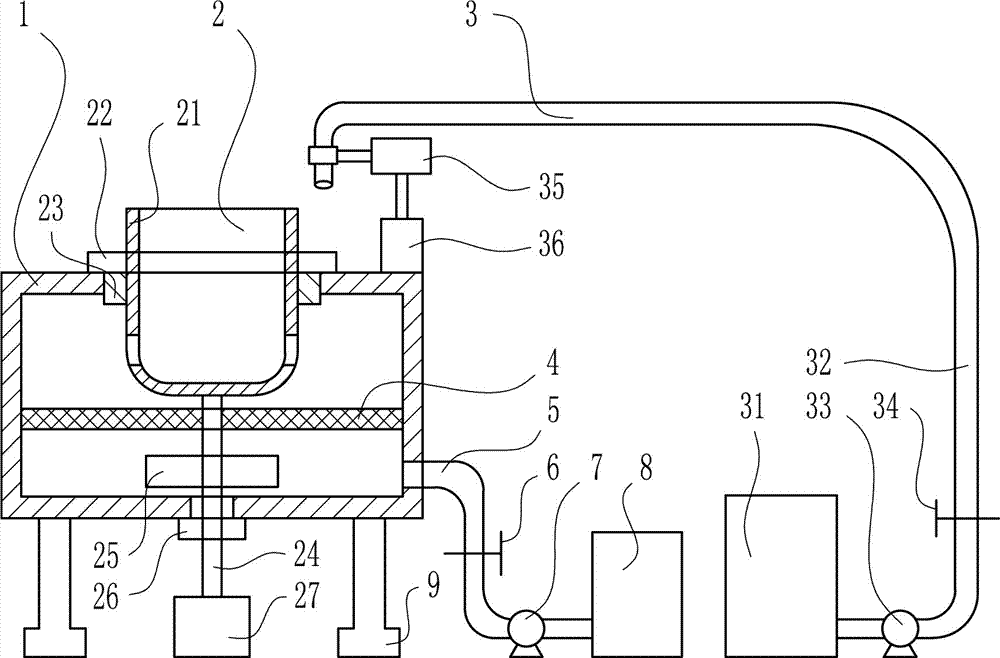

[0028] A quick degreasing device for rare earth feed liquid, such as Figure 1-4 As shown, it includes oil removal tank 1, rotating device 2, material receiving device 3, filter cloth 4, connecting pipe 5, valve I6, high pressure pump I7, material storage tank 8 and legs 9; the middle part of the top of oil removal tank 1 There is an opening, the rotating device 2 is installed on the oil removal tank 1, the material receiving liquid device 3 is arranged on the right side of the oil removal tank 1, the filter cloth 4 and the lower part of the inner wall of the oil removal tank 1 are connected by screws, and the right side of the oil removal tank 1 The lower part of the side wall is connected to the left end of the connecting pipe 5 by welding, the connecting pipe 5 communicates with the oil removal tank 1, and the connecting pipe 5 is equipped with a valve I6 and a high-pressure pump I7, and the high-pressure pump I7 is set on the right side of the valve I6. The right end of th...

Embodiment 2

[0030] A quick degreasing device for rare earth feed liquid, such as Figure 1-4 As shown, it includes oil removal tank 1, rotating device 2, material receiving device 3, filter cloth 4, connecting pipe 5, valve I6, high pressure pump I7, material storage tank 8 and legs 9; the middle part of the top of oil removal tank 1 There is an opening, the rotating device 2 is installed on the oil removal tank 1, the material receiving liquid device 3 is arranged on the right side of the oil removal tank 1, the filter cloth 4 and the lower part of the inner wall of the oil removal tank 1 are connected by screws, and the right side of the oil removal tank 1 The lower part of the side wall is connected to the left end of the connecting pipe 5 by welding, the connecting pipe 5 communicates with the oil removal tank 1, and the connecting pipe 5 is equipped with a valve I6 and a high-pressure pump I7, and the high-pressure pump I7 is set on the right side of the valve I6. The right end of th...

Embodiment 3

[0033] A quick degreasing device for rare earth feed liquid, such as Figure 1-4 As shown, it includes oil removal tank 1, rotating device 2, material receiving device 3, filter cloth 4, connecting pipe 5, valve I6, high pressure pump I7, material storage tank 8 and legs 9; the middle part of the top of oil removal tank 1 There is an opening, the rotating device 2 is installed on the oil removal tank 1, the material receiving liquid device 3 is arranged on the right side of the oil removal tank 1, the filter cloth 4 and the lower part of the inner wall of the oil removal tank 1 are connected by screws, and the right side of the oil removal tank 1 The lower part of the side wall is connected to the left end of the connecting pipe 5 by welding, the connecting pipe 5 communicates with the oil removal tank 1, and the connecting pipe 5 is equipped with a valve I6 and a high-pressure pump I7, and the high-pressure pump I7 is set on the right side of the valve I6. The right end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com