Water-based cleaning solution for cleaning printed circuit board and preparation method thereof

A water-based cleaning solution and printed circuit board technology, applied in the field of cleaning agents, can solve the problems of inability to completely remove organic dirt and particle dirt, adverse effects of processes or applications, and complicated cleaning waste liquid treatment, achieving excellent cleaning performance and easy cleaning. Effect of recycling and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

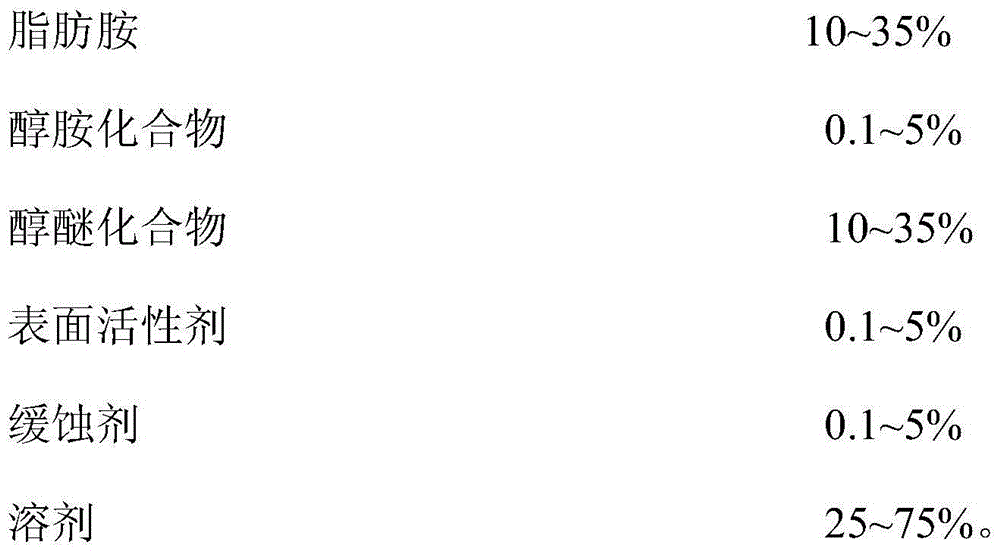

[0047] A kind of water-based cleaning solution for cleaning printed circuit boards of the present invention comprises the following raw materials in mass percentage:

[0048]

[0049] The fatty amine in this embodiment is 3-methoxypropylamine.

[0050] The alcohol amine compound in this embodiment is N-methyldiethanolamine.

[0051] The alcohol ether compound in this embodiment is diethylene glycol monomethyl ether.

[0052] The surfactant of the present embodiment is alkyltrimethyl quaternary ammonium salt.

[0053] The corrosion inhibitor in this embodiment is sodium metasilicate.

[0054] The solvent of this embodiment is pure water.

[0055] A preparation method for a water-based cleaning solution for cleaning printed circuit boards, comprising the following processing steps:

[0056] Step A. Accurately weigh the amount of materials according to the formula, and place them in different containers;

[0057] Step B, adding the solvent into the reaction kettle, then a...

Embodiment 2

[0063] A kind of water-based cleaning solution for cleaning printed circuit boards of the present invention comprises the following raw materials in mass percentage:

[0064]

[0065] The fatty amine in this embodiment is 3-ethoxypropylamine.

[0066] The alcohol amine compound in this embodiment is N,N-dimethylethanolamine.

[0067] The alcohol ether compound in this embodiment is triethylene glycol monomethyl ether.

[0068] The surfactant of the present embodiment is dialkyl dimethyl quaternary ammonium salt.

[0069] The corrosion inhibitor in this example is a benzotriazole derivative.

[0070] The solvent of this embodiment is pure water.

[0071] A preparation method for a water-based cleaning solution for cleaning printed circuit boards, comprising the following processing steps:

[0072] Step A. Accurately weigh the amount of materials according to the formula, and place them in different containers;

[0073] Step B, adding the solvent into the reaction kettle...

Embodiment 3

[0079] A kind of water-based cleaning solution for cleaning printed circuit boards of the present invention comprises the following raw materials in mass percentage:

[0080]

[0081]

[0082] The fatty amine in this embodiment is a mixture of 3-methoxypropylamine, 3-ethoxypropylamine and 3-isopropoxypropylamine.

[0083] The alcohol amine compound in this embodiment is a mixture of N-methyldiethanolamine, N,N-dimethylethanolamine and N-ethyldiethanolamine.

[0084] The alcohol ether compound in this embodiment is a mixture of diethylene glycol monomethyl ether, triethylene glycol monomethyl ether and diethylene glycol monobutyl ether.

[0085] The surfactant in this embodiment is a mixture of alkyl trimethyl quaternary ammonium salt, dialkyl dimethyl quaternary ammonium salt and monoalkyl quaternary ammonium salt.

[0086] The corrosion inhibitor in this embodiment is a mixture of sodium metasilicate, benzotriazole derivatives and alkanolamides.

[0087] The solvent o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com