Comfortable stretch yarn and wool blended yarn and production process thereof

A technology of wool blended yarn and production process, which is applied in the direction of yarn, textiles, papermaking, and textile materials in contact with export textile materials, etc. It can solve problems such as bulging shoulders, easy elongation and deformation, and loose sweaters. Improved recovery and good shape retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

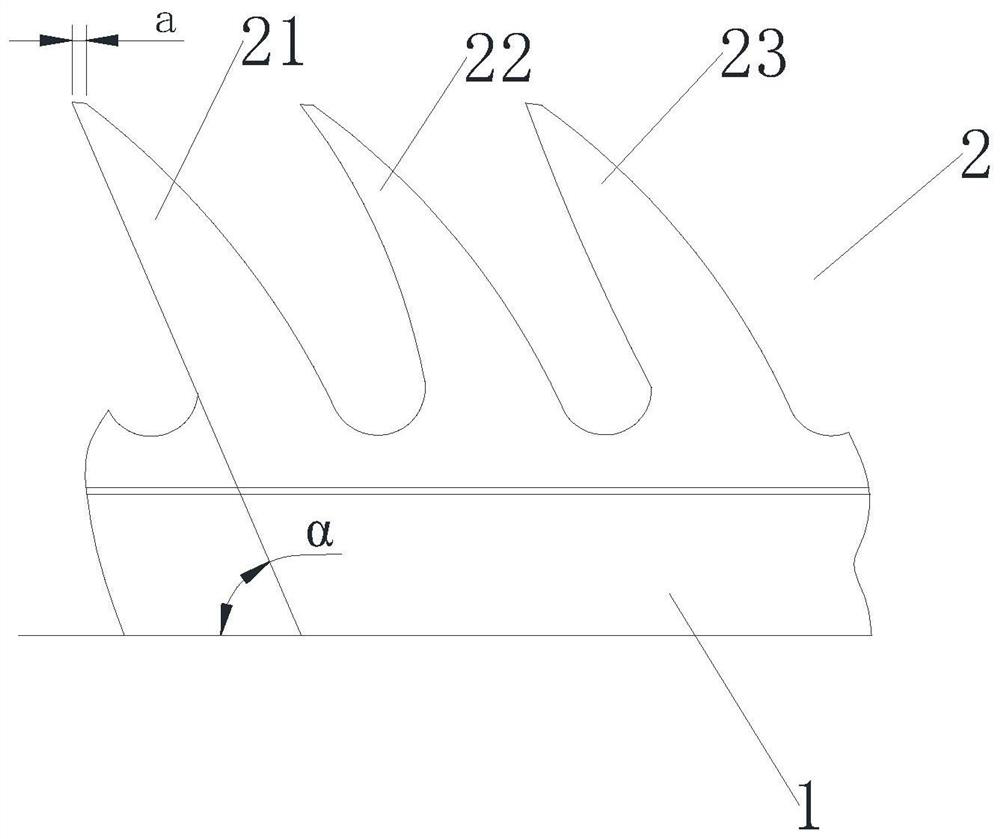

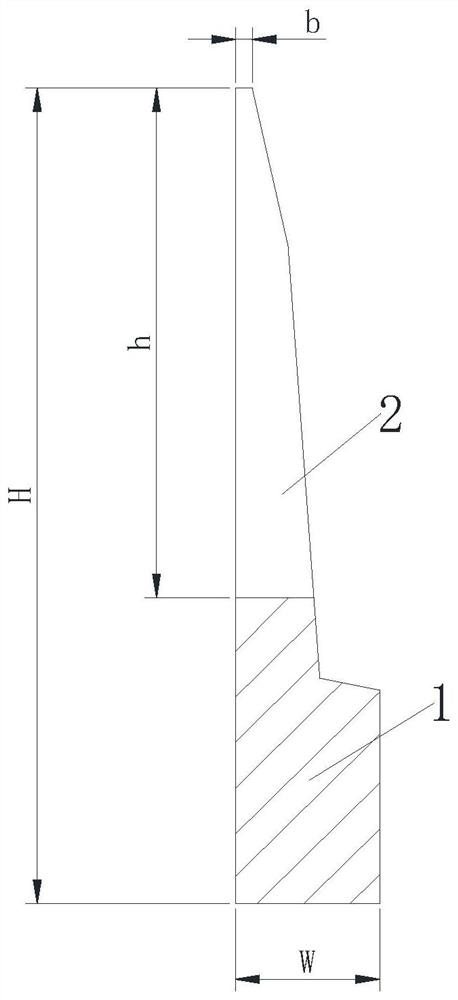

[0030] combine Figure 1 to Figure 5 , to describe this embodiment in detail. The stretchy wool blended yarn involved in this embodiment includes stretchy silk fiber, worsted Basolan wool, and anti-pilling acrylic fiber. The stretchy silk fiber is a spring-like spiral curl, with a large degree of curl, good elasticity and resilience. Anti-pilling acrylic can greatly improve the anti-pilling properties of blended yarns. As a result, the sweater prepared by the elastic silk wool blended yarn will hardly appear bulging in the hanging amount, and will not elongate due to the influence of gravity when hanging.

[0031] Further, the stretch fiber accounts for 40% by weight of the blended yarn, the worsted Basolan wool accounts for 30% by weight of the blended yarn, and the anti-pilling acrylic fiber accounts for 30% by weight of the blended yarn. The weight percentage is 30%.

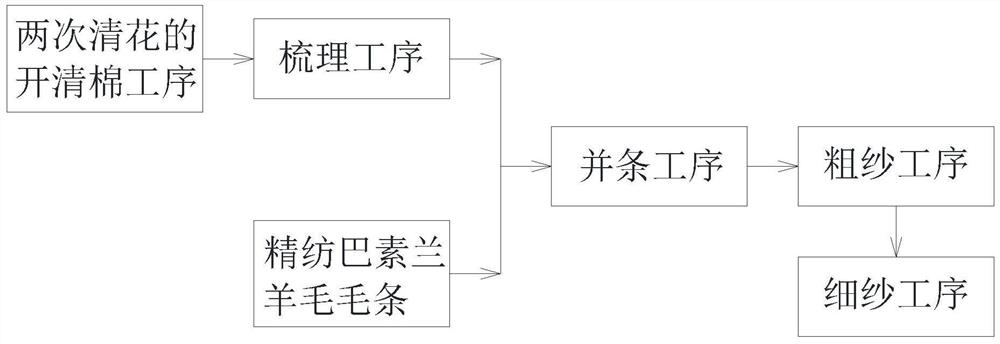

[0032] This embodiment relates to a production process of elastic silk wool blended yarn, the preparat...

Embodiment 2

[0050] The difference between the production process of the elastic silk wool blended yarn involved in this embodiment and the first embodiment is that it also includes a dyeing process, and the dyeing includes the following steps:

[0051] Wind the prepared spun yarn onto a dyed plastic bobbin with holes, the bobbin used is cylindrical; the yarn density of the bobbin is controlled at 0.23-0.25g / cm 3 ; Rotate the bobbins layer by layer on each dye solution spray column on the dyeing creel, and fix the layers with spacers; then place the dyeing cage full of bobbins in a sealed bobbin vat; The weight of the yarns on the root dye spray column is the same and the arrangement is uniform;

[0052] For pre-dyeing treatment, inject the pre-dyeing treatment solution into the dye vat according to the bath ratio of 1:12-15, and the pre-treatment solution contains 40-50ml / L of 30% hydrogen peroxide, 4-5g / L of Sodium caramelate, 1-2g / L penetrant JFC, hydrogen bond breaker with a molar vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tooth depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com