Sprayed concrete

A technology of sprayed concrete and quick-setting agent, which is applied in the field of concrete, can solve the problems that the splitting tensile strength and flexural strength cannot meet the needs of underground civil engineering, and achieve the effect of improving the splitting tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

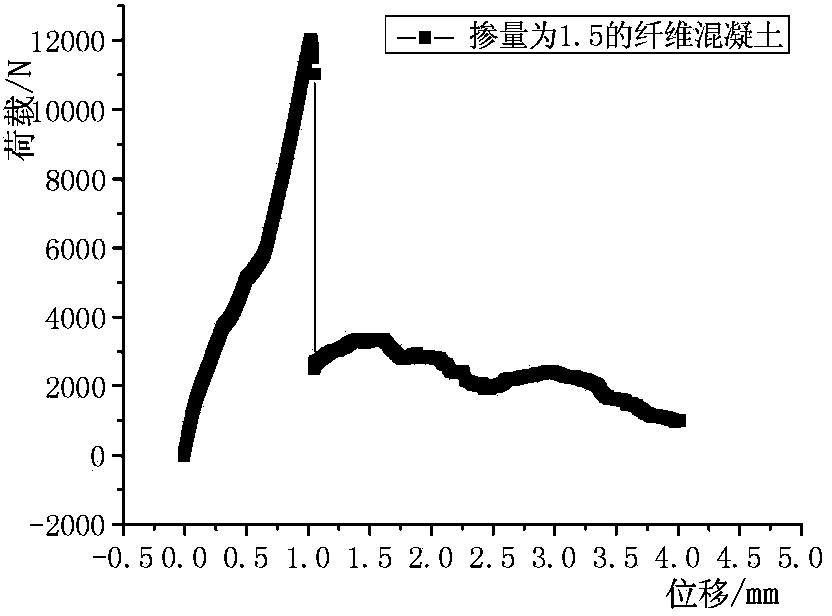

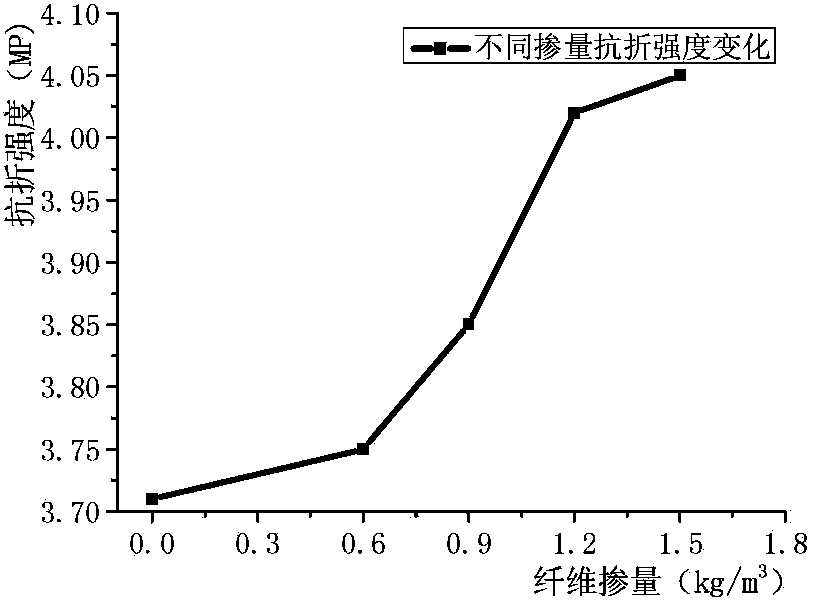

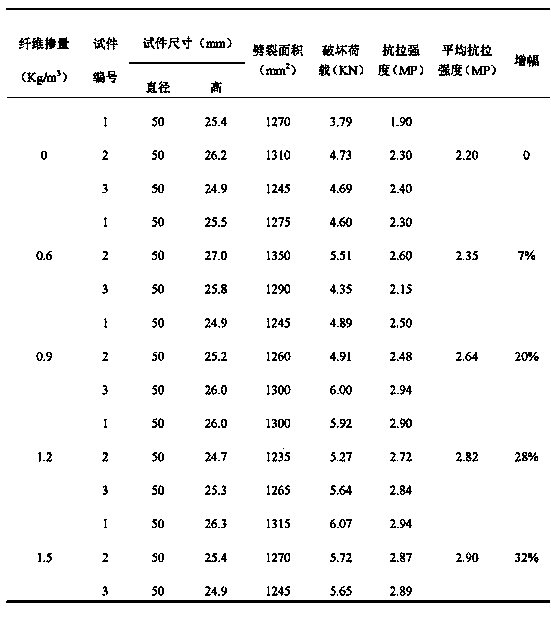

[0013] A shotcrete whose components include cement, sand, stones, water, quick-setting agent, and bundled monofilament polypropylene fibers, wherein the weight ratio of the components cement, sand, stones, and water is 1:1.84:1.84: 0.45, the amount of quick-setting agent is 2%~4% of the weight of cement, and the amount of polypropylene fiber is 0.6 kg / m 3 ~1.5 kg / m 3 .

[0014] In the present invention, the cement is preferably Portland cement or ordinary Portland cement whose grade is not lower than P.O42.5. Because the C of these two cements 3 S and C 3 The content of A is higher, the compatibility with the accelerator is good, it can set quickly and harden quickly, and the later strength is also higher.

[0015] In the present invention, the sand is preferably coarse sand with a fineness modulus greater than 2.5. If the sand is too fine, the dry shrinkage of the concrete will increase; if the sand is too coarse, the rebound will increase. Particles smaller than 0.075m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com