Novel high-strength anti-rutting modified asphalt and preparation method thereof

A modified asphalt, high-strength technology, used in building components, building insulation materials, construction and other directions, can solve the problem of insufficient rutting resistance of modified asphalt, achieve good high-strength anti-rutting performance, good economic benefits, increase driving The effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

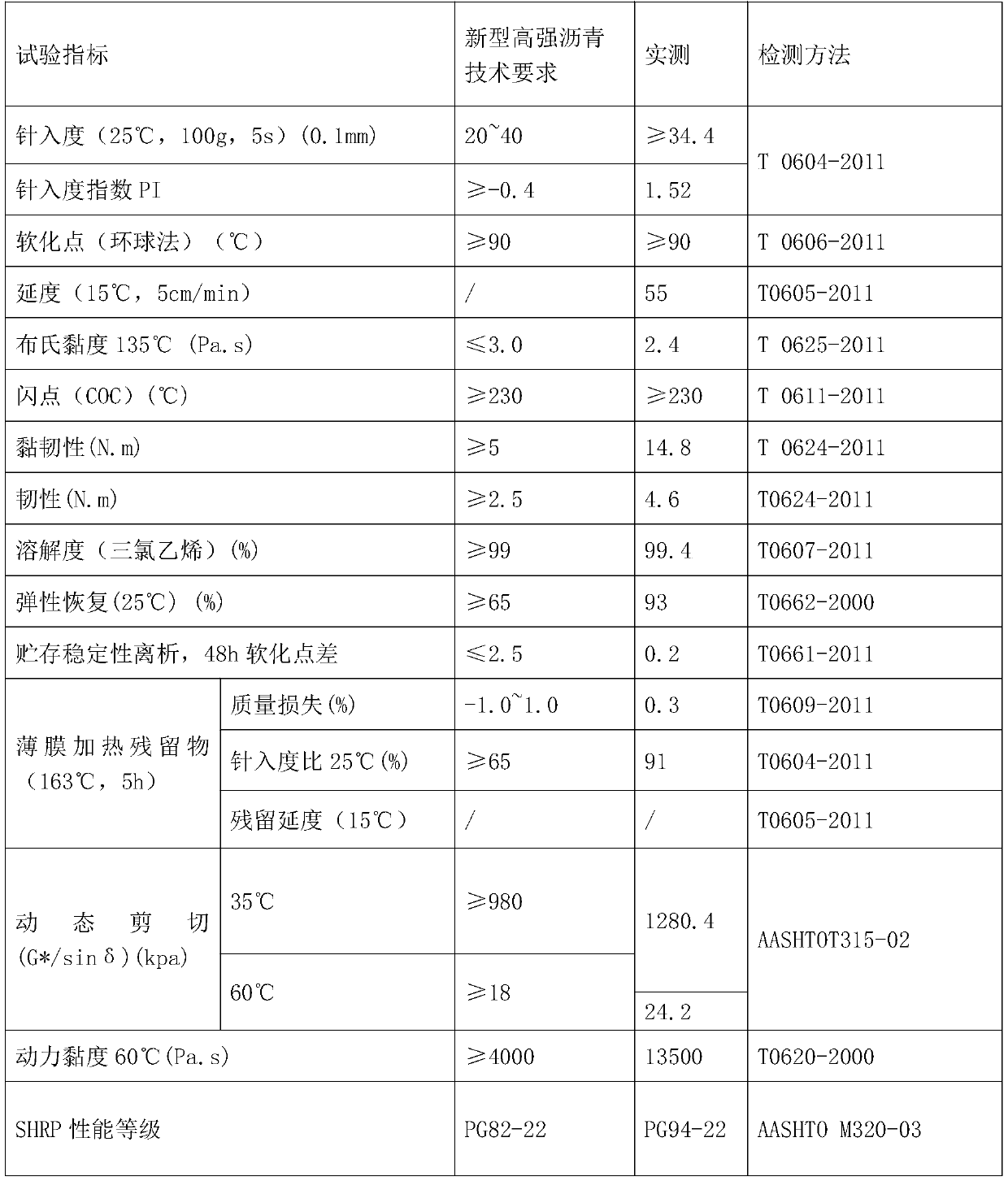

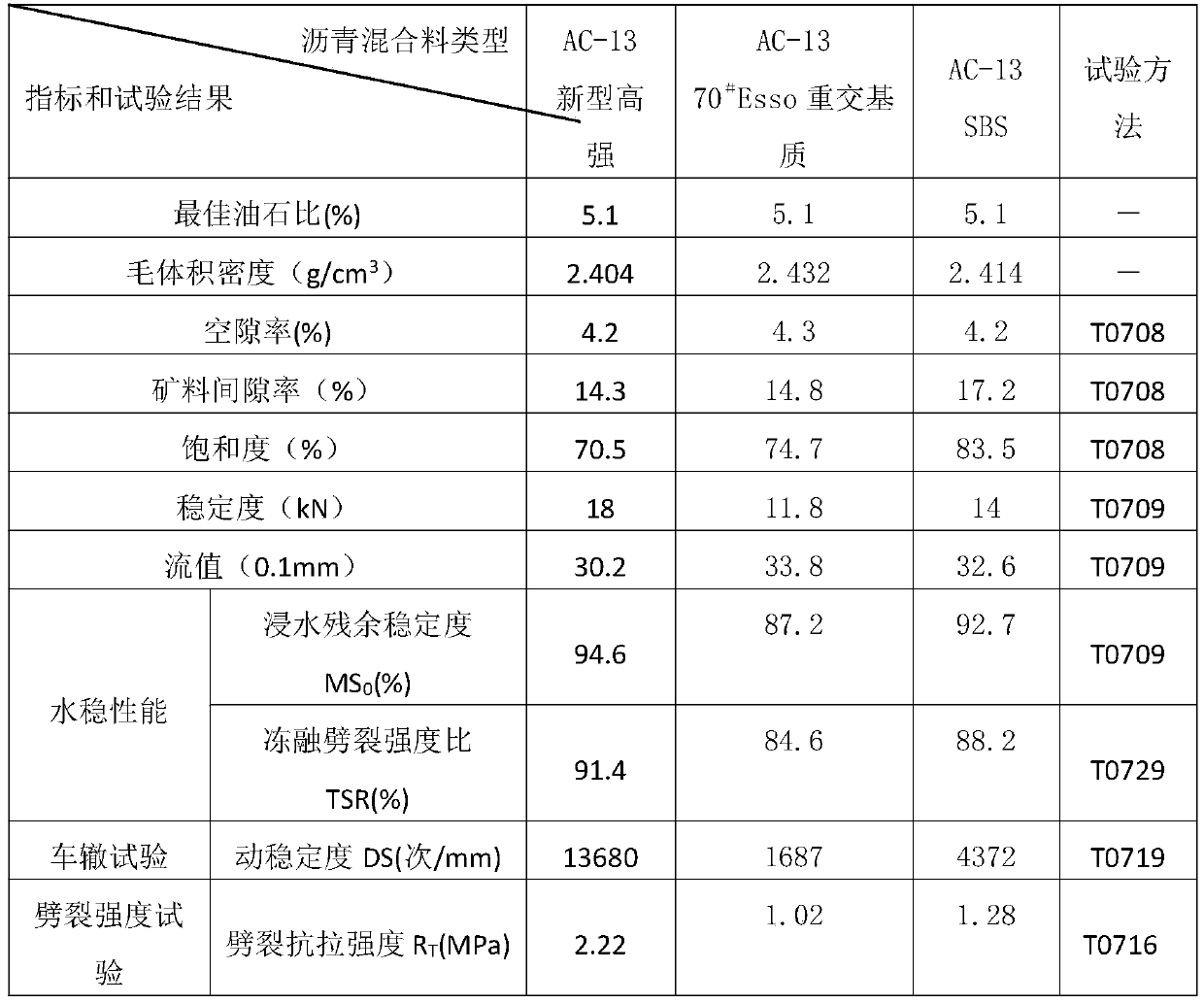

Embodiment 1

[0028] A new type of high-strength anti-rutting modified asphalt, including 70 # Esso heavy traffic asphalt, modifiers and additives, the additives include anti-rutting agent, stabilizer and cosolvent, modifier is SBST161B, cosolvent is lime cosolvent; wherein the mass percentage of each component is: 70 # Esso heavy traffic asphalt 89%, modifier 4.3%, anti-rutting agent 4.3%, stabilizer 0.42% and co-solvent 2.1%.

[0029] The anti-rutting agent is composed of the following raw materials in mass percentage: 40% of RA resin, 45% of styrene-butadiene rubber and 15% of rosin stabilizer.

[0030] The stabilizer is composed of the following raw materials in parts by weight: 60 parts of sulfur powder, 8 parts of carbon black, 5 parts of nano zinc oxide, 3 parts of muscovite powder and 6 parts of light calcium carbonate. The preparation method of described stabilizer comprises the following steps:

[0031] (1) Take each raw material according to the proportioning ratio, and dry the...

Embodiment 2

[0040] A new type of high-strength anti-rutting modified asphalt, including 70 # Esso heavy traffic asphalt, modifiers and additives, the additives include anti-rutting agent, SASOBIT, stabilizer and co-solvent, modifier is SBST161B, co-solvent is lime co-solvent; wherein the mass percentage of each component is: 70 # Esso heavy traffic asphalt 89%, modifier 4.3%, anti-rutting agent 4.3%, SASOBIT 2.1%, stabilizer 0.42% and co-solvent 2.1%.

[0041] The anti-rutting agent is composed of the following raw materials in mass percentage: 35% of RA resin, 50% of styrene-butadiene rubber and 18% of rosin stabilizer.

[0042] The stabilizer is composed of the following raw materials in parts by weight: 50 parts of sulfur powder, 10 parts of carbon black, 10 parts of nano zinc oxide, 1 part of muscovite powder and 10 parts of light calcium carbonate. The preparation method of described stabilizer comprises the following steps:

[0043] (1) Take each raw material according to the prop...

Embodiment 3

[0052] A new type of high-strength anti-rutting modified asphalt, including 70 # Esso heavy traffic asphalt, modifiers and additives, the additives include anti-rutting agent, SASOBIT, stabilizer and co-solvent, modifier is SBST161B, co-solvent is lime co-solvent; wherein the mass percentage of each component is: 70 # Esso heavy traffic asphalt 89%, modifier 4.3%, anti-rutting agent 4.3%, SASOBIT 2.1%, stabilizer 0.42% and co-solvent 2.1%.

[0053] The anti-rutting agent is composed of the following raw materials in mass percentage: 45% of RA resin, 40% of styrene-butadiene rubber and 12% of rosin stabilizer.

[0054] The stabilizer is composed of the following raw materials in parts by weight: 80 parts of sulfur powder, 5 parts of carbon black, 1 part of nano zinc oxide, 5 parts of muscovite powder and 1 part of light calcium carbonate. The preparation method of described stabilizer comprises the following steps:

[0055] (1) Take each raw material according to the proporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com