Material for treating pavement segregation

A cationic and emulsification treatment technology, used in building thermal insulation materials, building components, buildings, etc., can solve the problems of oil flooding and limited treatment effect, and achieve the effects of good water and workability, good fluidity, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

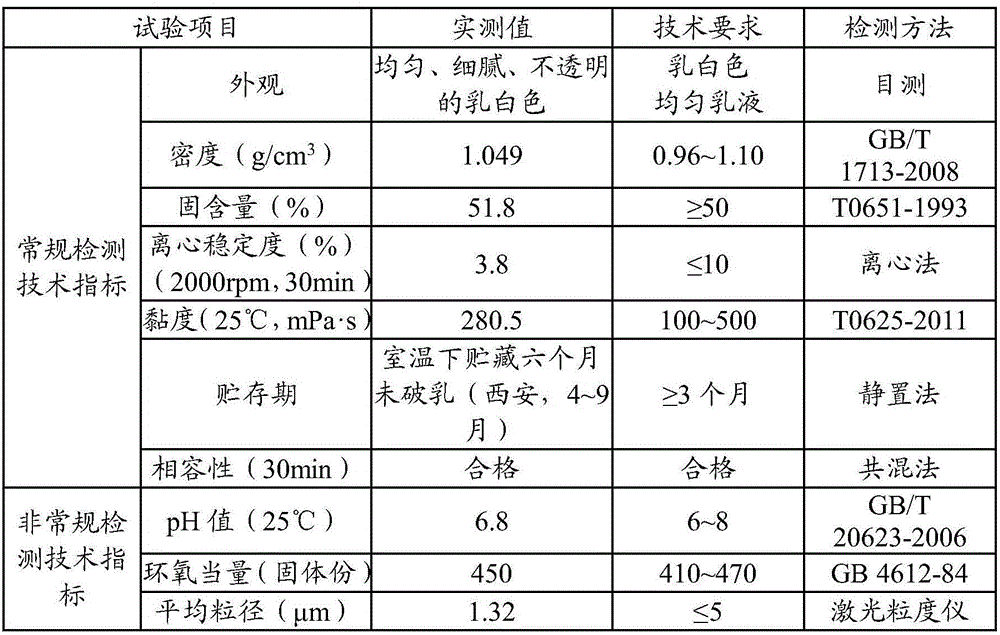

[0042] In the present invention, the preparation method of described aqueous epoxy resin emulsion preferably comprises the steps:

[0043] Carry out softening treatment to bisphenol A epoxy resin;

[0044] The softened bisphenol A epoxy resin is emulsified with a compounded emulsifier and water to obtain an aqueous epoxy resin emulsion.

[0045] The invention softens the bisphenol A epoxy resin to obtain the softened bisphenol A epoxy resin. In the present invention, the temperature of the softening treatment is preferably 25-35°C, more preferably 28-33°C, and most preferably 30-31°C. In the present invention, there is no special requirement on the softening treatment time, as long as the bisphenol A epoxy resin can be softened, it is about 1 minute. In the present invention, the softening treatment is preferably carried out under the condition of stirring, so that the bisphenol A epoxy resin is heated evenly and the softening process is accelerated.

[0046] After the soft...

Embodiment 1

[0079] Water-based epoxy resin: soften 11 parts of bisphenol A epoxy resin at 30°C, and mix with 6 parts of alkylphenol polyoxyethylene ether and 3 parts of cetyltrimethylammonium chloride after softening, stirring While adding hot water preheated to 70°C, emulsify at 70°C for 30 minutes to obtain a water-based epoxy resin emulsion.

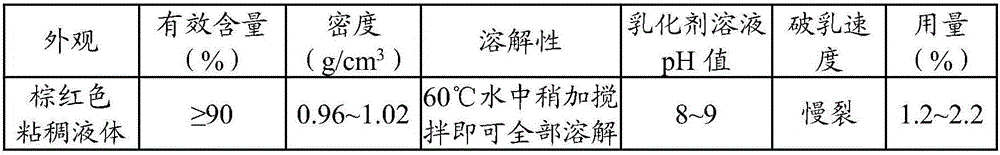

[0080] Cationic emulsified asphalt: at a temperature of 280°C, hydrolyze 1 part of cottonseed oil in 4 parts of water for 25 minutes to obtain mixed fatty acids; react the long-chain mixed fatty acids with maleic acid to obtain tricarboxylic acid intermediates; A cationic asphalt emulsifier is obtained by reacting tricarboxylic acid intermediates with polyethylene polyamines.

[0081] The 30 parts product model is SK90 # Asphalt, 4 parts of cationic asphalt emulsifier and 40 parts of water are mixed to obtain cationic emulsified asphalt.

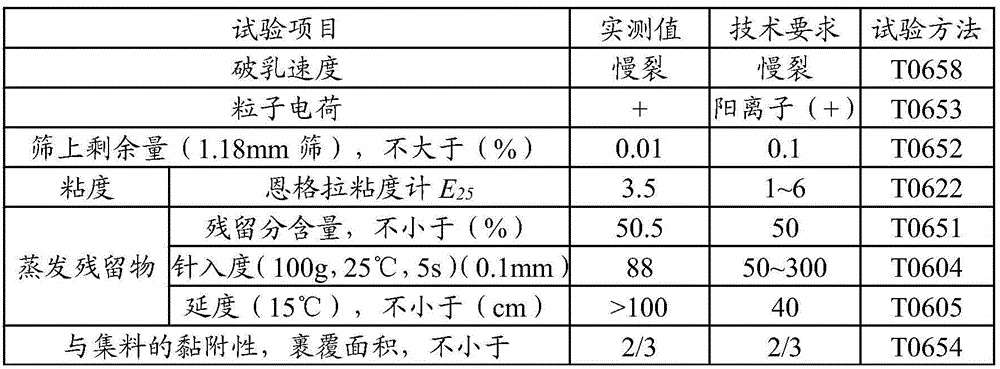

[0082] A mixture of 50 parts of water-based epoxy resin emulsion and 35 parts of cationic emulsified aspha...

Embodiment 2

[0097] Water-based epoxy resin: soften 11 parts of bisphenol A epoxy resin at 30°C, and mix with 6 parts of alkylphenol polyoxyethylene ether and 3 parts of cetyltrimethylammonium chloride after softening, stirring While adding hot water preheated to 70°C, emulsify at 70°C for 30 minutes to obtain a water-based epoxy resin emulsion.

[0098] Cationic emulsified asphalt: at 270°C, hydrolyze 1 part of cottonseed oil in 3 parts of water for 30 minutes to obtain mixed fatty acids; react the long carbon chain mixed fatty acids with maleic acid to obtain tricarboxylic acid intermediates; A cationic asphalt emulsifier is obtained by reacting tricarboxylic acid intermediates with polyethylene polyamines.

[0099]The 70 parts product model is SK90 # Asphalt, 3 parts of cationic asphalt emulsifier and 50 parts of water are mixed to obtain cationic emulsified asphalt.

[0100] A mixture of 40 parts of water-based epoxy resin emulsion and 40 parts of cationic emulsified asphalt is mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com