Nano-metakaolin recycled concrete and preparation method thereof

A technology of recycled concrete and metakaolin, applied in the field of concrete, can solve the problems of high cost and limited application prospects, and achieve the effects of improved ductility, good application prospects and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

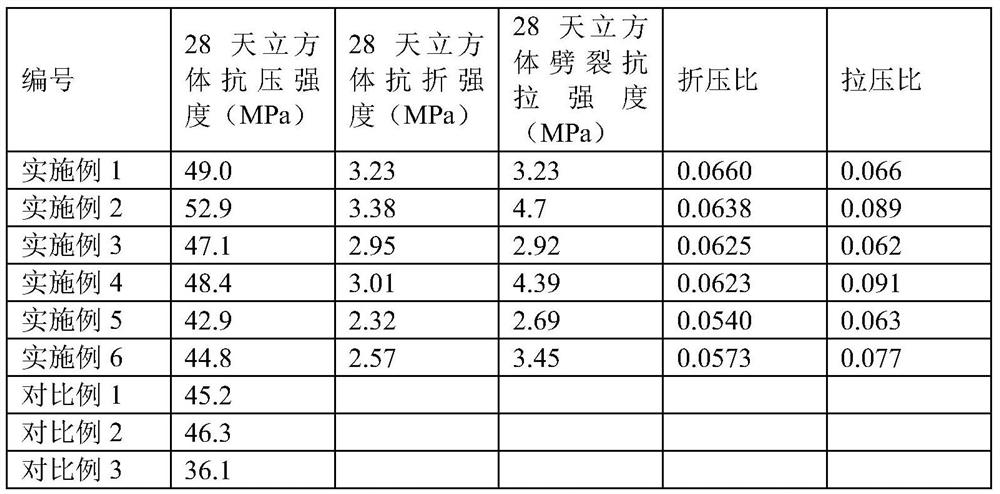

Examples

Embodiment 1

[0027] Embodiment 1: a kind of nanometer metakaolin regeneration concrete, its raw material comprises the component of following parts by weight:

[0028] 361.81 parts of cement;

[0029] Nano metakaolin 11.19 parts;

[0030] Sand 619 parts;

[0031] 842 parts of natural coarse aggregate;

[0032] 361 parts of recycled coarse aggregate;

[0033] 211 parts of water;

[0034] The preparation method of recycled coarse aggregate is as follows:

[0035] Step 1: After the recycled coarse aggregate is manually crushed into large pieces, the jaw crusher is used for further crushing, so that the crushed aggregate is roughly 31mm or less.

[0036] Step 2: After crushing, pass through a 4.75mm square hole sieve first, discard the particles smaller than 4.75mm directly, choose a square hole sieve of 4.75mm, 9.5mm, 19.0mm, 31.5mm and a bottom sieve each, and carry out crushing on the crushed aggregate. Fine sieve, the sieved aggregate particle size ranges are 5 ~ 10mm, 10 ~ 20mm, 20 ...

Embodiment 2

[0041] Embodiment 2: A nano-metakaolin recycled concrete. The difference from the embodiment 1 is that the weight part of cement is 354.35 parts, and the weight part of nano-metakaolin is 18.65 parts.

Embodiment 3

[0042] Embodiment 3: a kind of nano metakaolin recycled concrete, the difference with embodiment 1 is that the parts by weight of natural coarse aggregate are 601.5 parts, the parts by weight of recycled coarse aggregate are 601.5 parts, and the parts by weight of water The number is 215 copies.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com