Self-cooling infrared asphalt mixture and preparation method thereof

A technology of asphalt mixture and self-radiation, applied in the direction of climate change adaptation, etc., can solve problems such as high cost and complicated construction technology, and achieve the effect of increasing cohesive force, increasing internal surface area, and reducing heat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

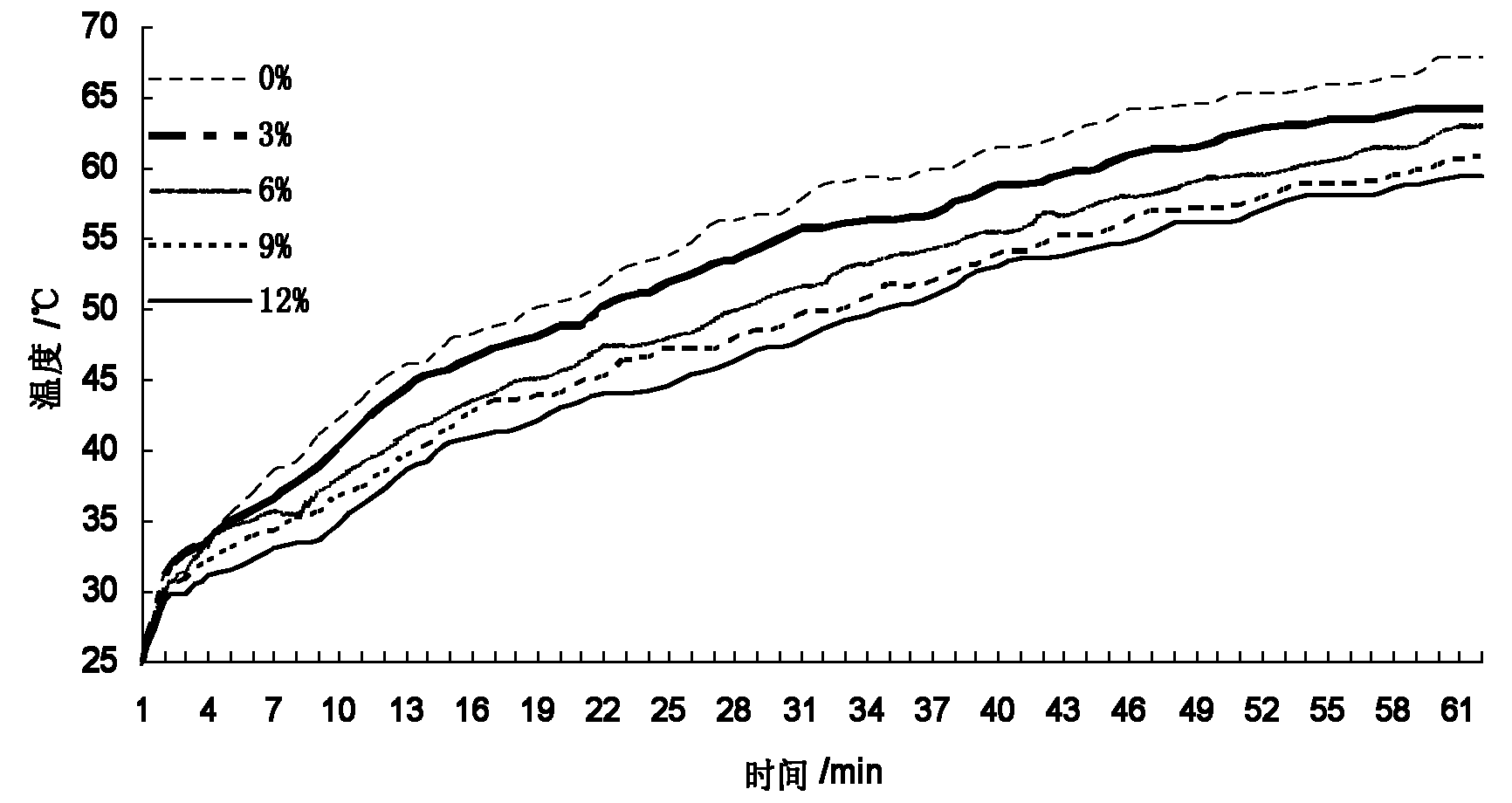

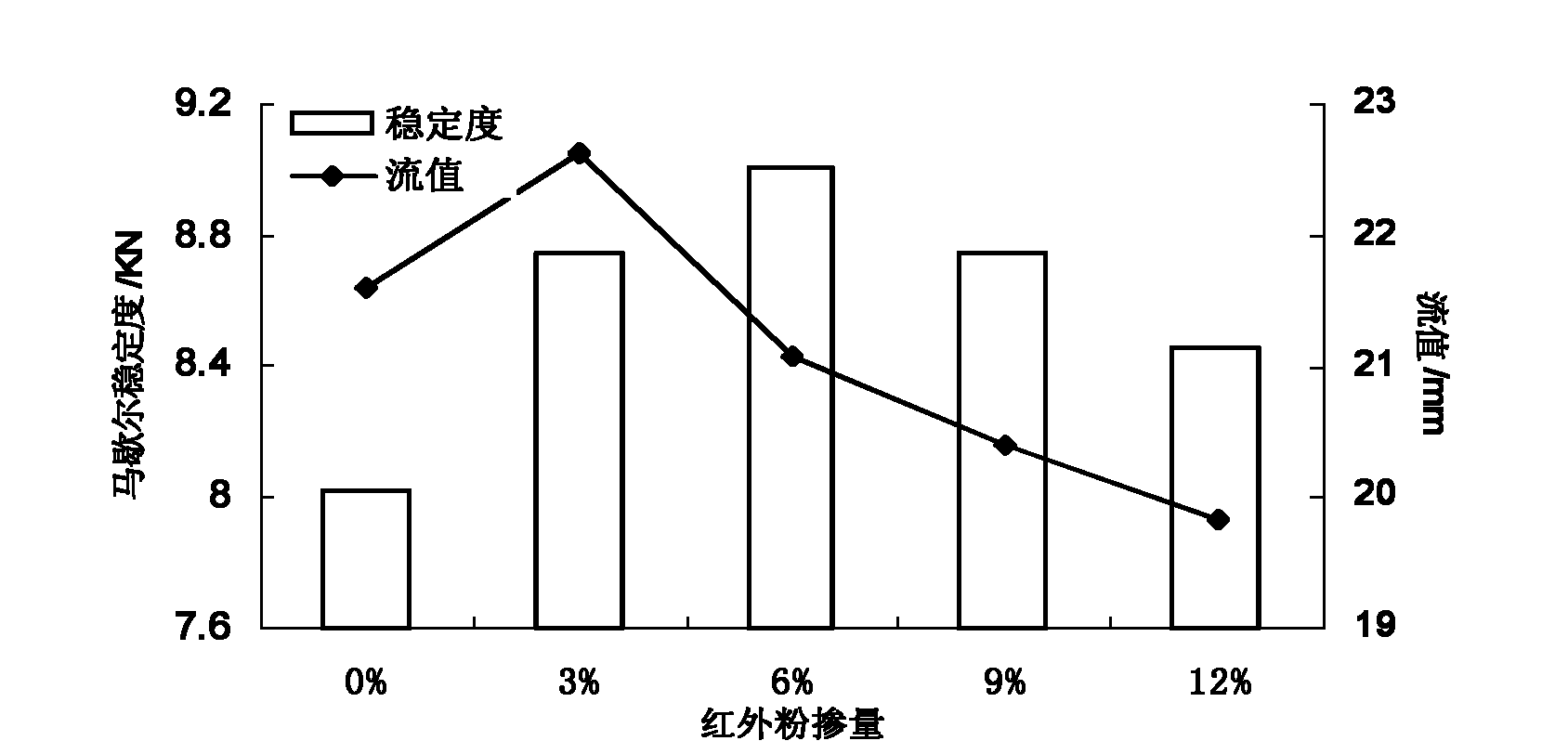

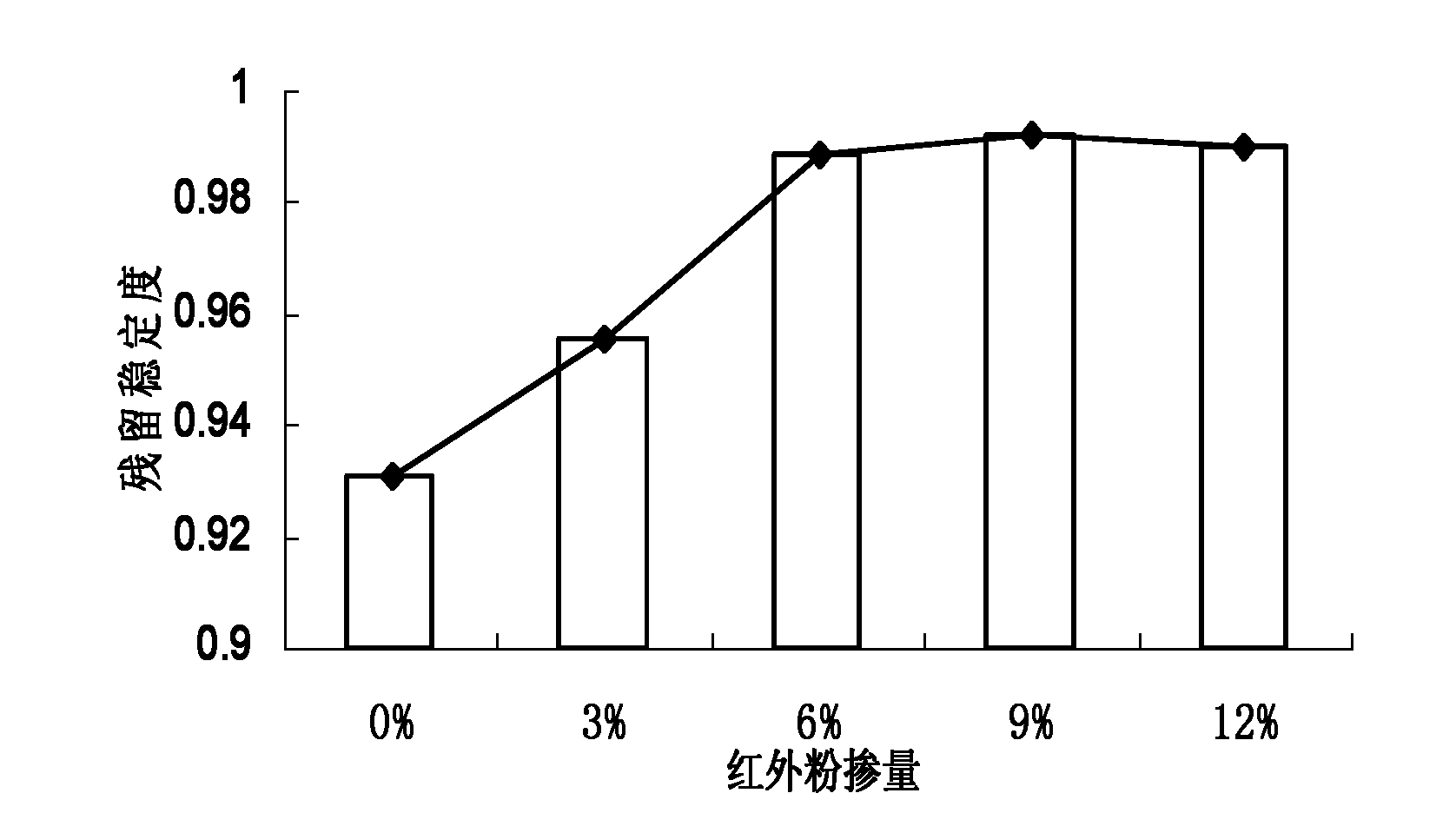

[0041] The self-radiating infrared asphalt mixture was prepared with 6% of infrared powder, and its surface equilibrium temperature, Marshall stability, residual stability, and -10°C low-temperature splitting tensile strength reached 61.34°C, 9.005KN, and 99.0% respectively and 3.089MPa; compared with asphalt mixture without infrared powder, the surface equilibrium temperature decreased by 5.25°C, and the Marshall stability, residual stability, and -10°C low-temperature splitting tensile strength increased by 12.23%, 6.34%, and 30.83% respectively %.

Embodiment 2

[0043]The self-radiating infrared asphalt mixture was prepared with 9% of infrared powder, and its surface equilibrium temperature, Marshall stability, residual stability, and low-temperature splitting tensile strength at -10°C reached 59.49°C, 8.742KN, and 99.1% respectively and 3.339MPa; compared with asphalt mixture without infrared powder, the surface equilibrium temperature decreased by 7.1°C, and the Marshall stability, residual stability, and -10°C low-temperature splitting tensile strength increased by 8.95%, 6.44%, and 41.42%, respectively. %.

Embodiment 3

[0045] The self-radiating infrared asphalt mixture was prepared with 12% of infrared powder, and its surface equilibrium temperature, Marshall stability, residual stability, and -10°C low-temperature splitting tensile strength reached 58.57°C, 8.453KN, and 99.0% respectively and 3.535MPa; Compared with the asphalt mixture without infrared powder, the surface equilibrium temperature decreased by 8.02℃, Marshall stability, residual stability, and -10℃ low temperature splitting tensile strength increased by 5.35%, 6.34% and 49.72% respectively %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com