Hybrid fiber reinforced concrete, and preparation method and application thereof

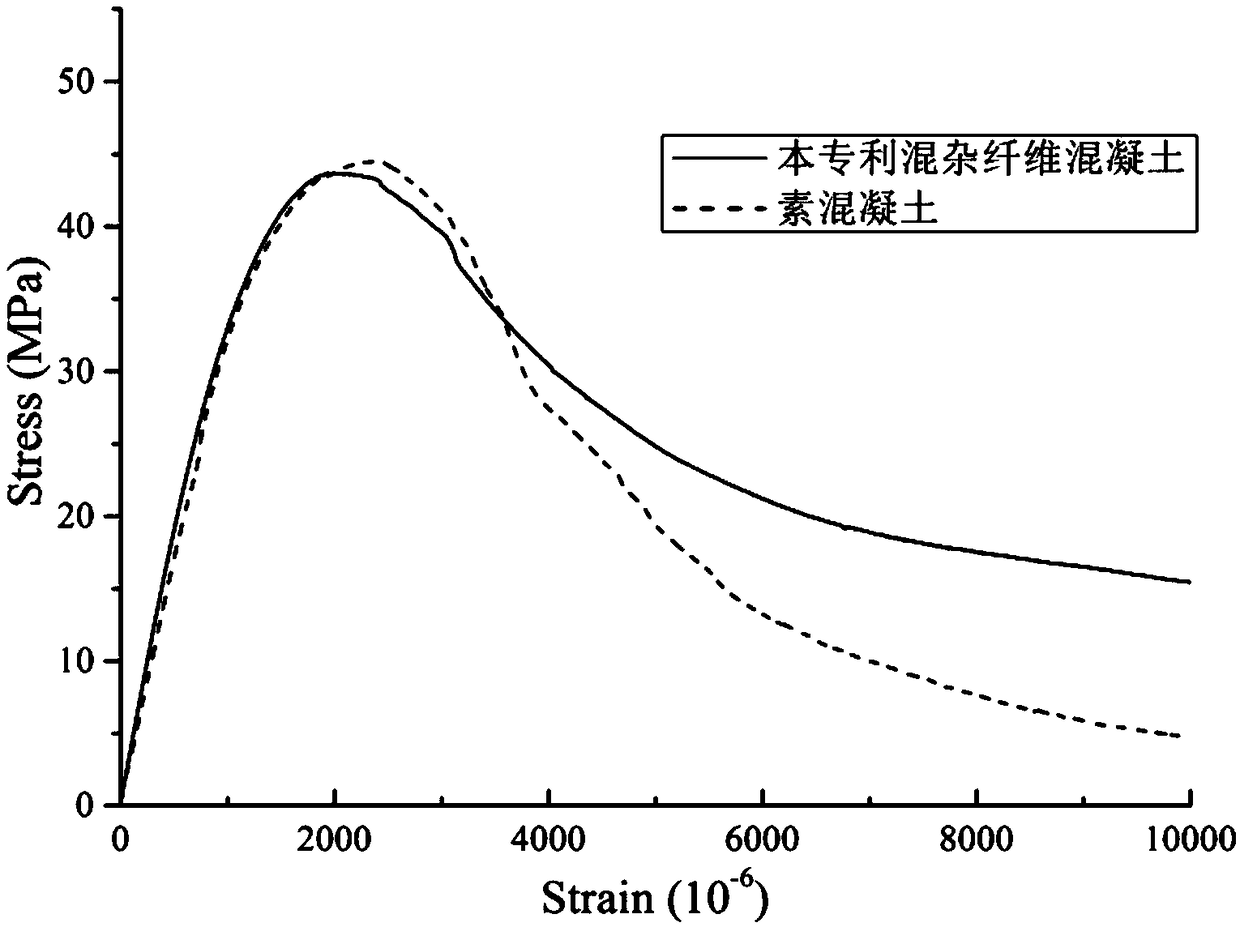

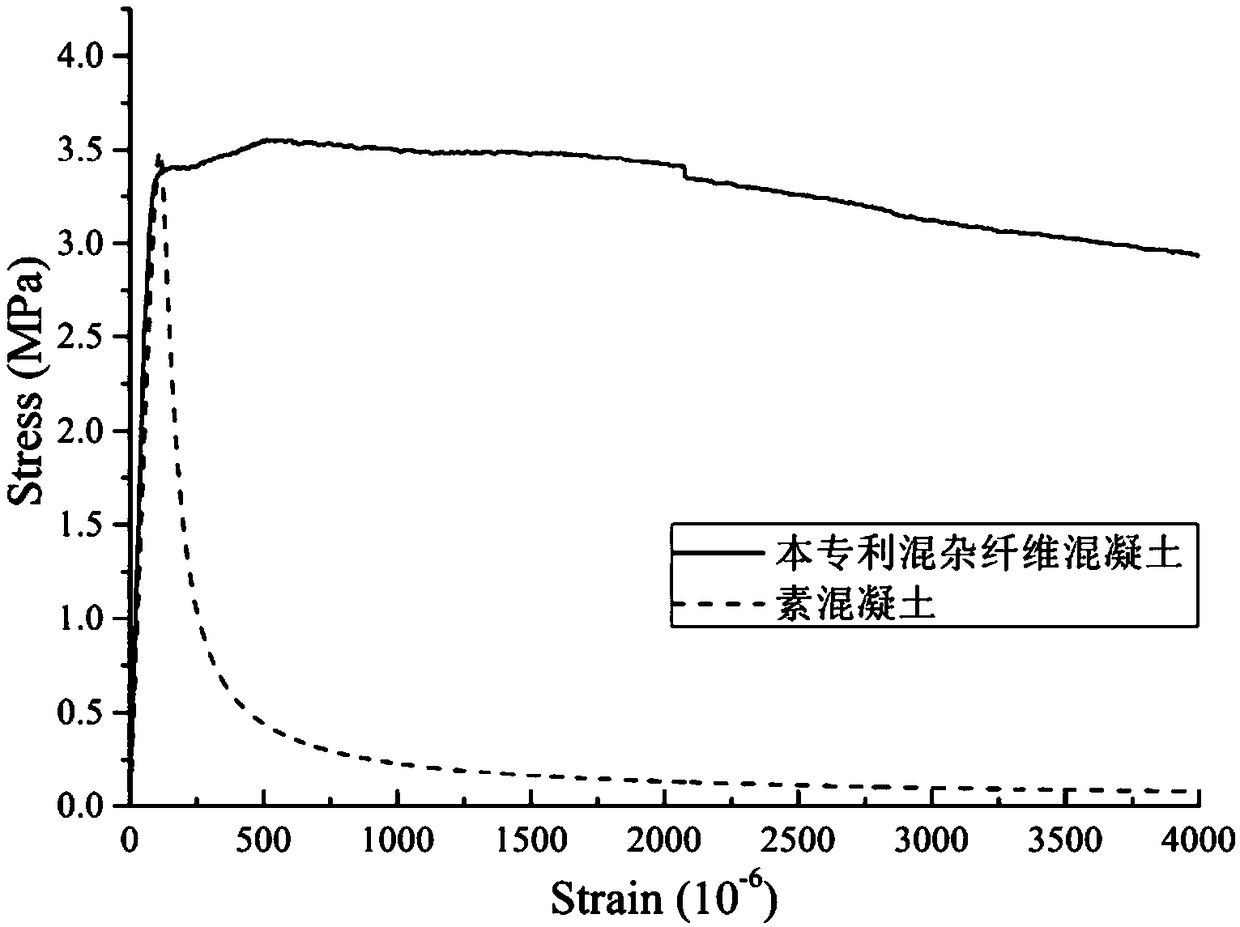

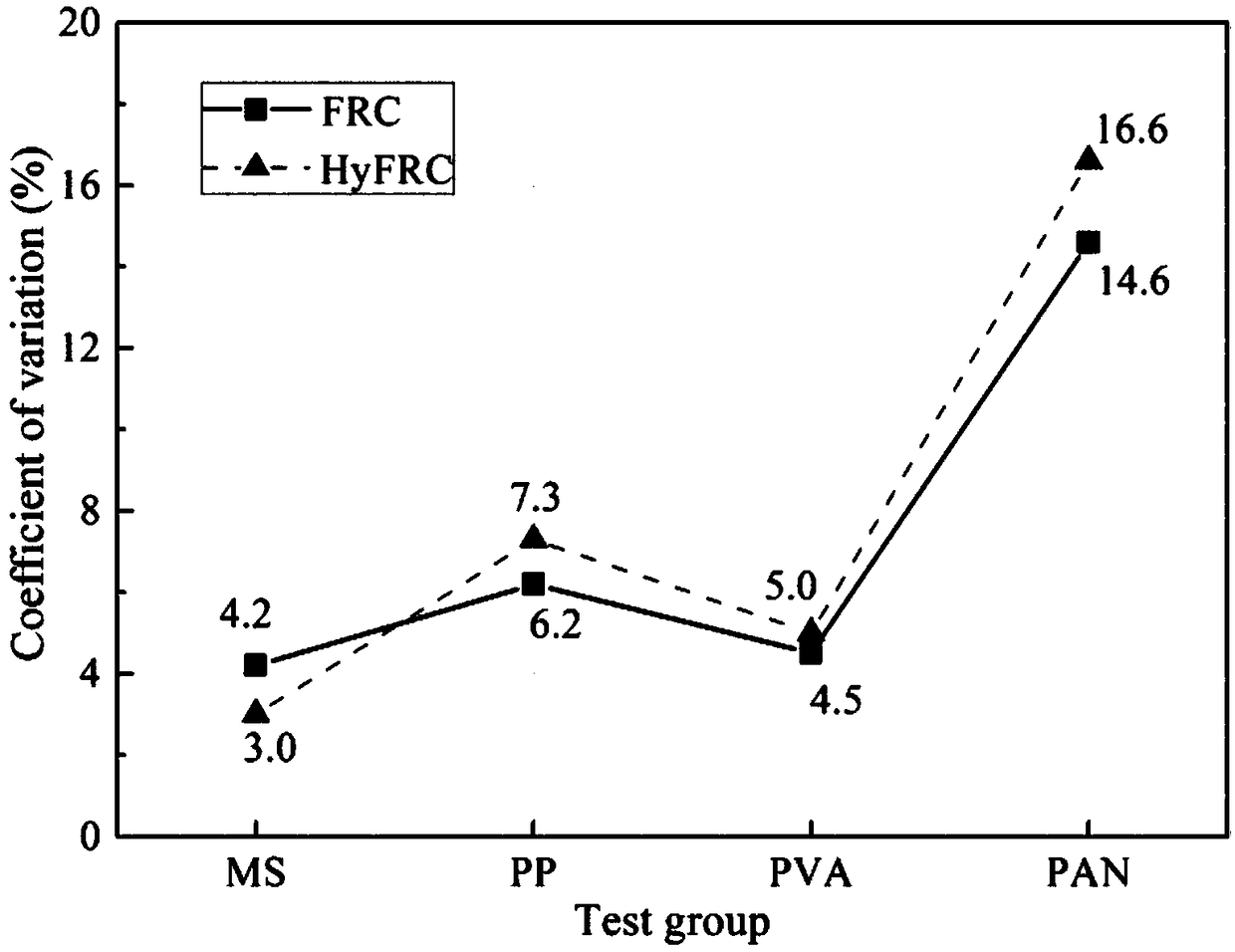

A hybrid fiber and concrete technology, applied in the field of building materials, can solve the problems of engineering application difficulties, failure to determine the fiber type and dosage parameters, and the difficulty of fiber reinforced concrete to achieve mechanical properties and working properties, and improve the splitting tensile strength. , Easy to construct quickly in large quantities, and the effect of improving uniaxial tensile toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0086]

[0087] The first step is to determine the concrete mix ratio and fiber mixing volume ratio, that is, according to the required cement grade, use the trial mix method to determine the mix ratio of each material of the concrete, and at the same time determine the volume of the steel fiber and polyvinyl alcohol fiber mixed Compare.

[0088] The second part prepares the required materials, that is, prepares the required coarse aggregate (stone), fine aggregate (sand), cement, water, water reducing agent, steel fiber and polyvinyl alcohol according to the material mix ratio of the mixed fiber concrete fiber.

[0089] In the third step, add the above-mentioned raw materials into the mixer and mix them.

[0090] Specifically, a kind of preparation method of hybrid fiber concrete, it comprises the steps:

[0091] (1) First add the coarse aggregate into the mixer, sprinkle steel fibers during the mixing process, and stir for 1-2 minutes to obtain the first mixture;

[009...

Embodiment 1

[0107] The hybrid fiber concrete of the present embodiment comprises the following components:

[0108]

[0109] Wherein, the batching ratio and specific components of the hybrid fiber concrete in this embodiment are as follows: the water-cement ratio is 0.45, and the sand rate is 40%.

[0110] Specifically, the cement is Conch brand 42.5 grade ordinary Portland cement, with a 28-day compressive strength of 45MPa and a density of 3015kg / m 3 .

[0111] The particle size of the coarse aggregate is 10mm and the density is 2620kg / m 3 .

[0112] The fine aggregate is medium-coarse river sand with a fineness modulus of 2.3 and a density of 2640kg / m 3 , the apparent density is 2.58g / cm 3 , bulk density is 1.48×103kg / m 3 .

[0113] The steel fiber is Dramix steel fiber produced by Bekaert, the model is 3D / 65 / 50BG, the diameter is 0.75mm, the length is 36.5mm, the tensile strength is 1225MPa, and the elastic modulus is 200000MPa. The volume content in hybrid fiber concrete is...

Embodiment 2

[0122] The hybrid fiber concrete of the present embodiment comprises the following components:

[0123] A hybrid fiber concrete comprising the following components:

[0124]

[0125] Wherein, the batching ratio and specific components of the hybrid fiber concrete in this embodiment are as follows: the water-cement ratio is 0.45, and the sand rate is 40%.

[0126] Specifically, the cement is Conch brand 42.5 grade ordinary Portland cement with a 28-day compressive strength of 60MPa and a density of 3562kg / m 3 .

[0127] The particle size of the coarse aggregate is 16mm and the density is 3008kg / m 3 .

[0128] The fine aggregate is medium-coarse river sand with a fineness modulus of 3.0 and a density of 2876kg / m 3 , the apparent density is 3.02g / cm 3 , bulk density is 1.48×103kg / m 3 .

[0129]The steel fiber is Dramix steel fiber produced by Bekaert, the model is 3D / 65 / 50BG, the diameter is 0.91mm, the length is 50mm, the tensile strength is 1352MPa, and the modulus of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com