PVA-basalt hybrid fiber high-toughness concrete capable of realizing 3D printing and use method thereof

A technology of basalt fiber and hybrid fiber, which is applied in the field of building materials, can solve the problems of relatively low water content and high water consumption, and achieve the effects of easy dispersion, increased splitting tensile strength, and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A method for preparing a 3D-printable PVA-basalt hybrid fiber high-toughness concrete material, the preparation method comprising the following steps:

[0039] In terms of parts by weight, pour 0.8-1.2 parts of rapid hardening ordinary Portland cement, 0.96-1.44 parts of F-class fly ash and 0.64-0.96 parts of quartz sand into the mixer and stir for 2-3 minutes; Pour 2 / 3 of the mixture of 0.43 parts and 0.005-0.01 parts of water reducer into the mixer and stir for 5-6 minutes; then pour the remaining 1 / 3 of the mixture of water and water reducer into the mixer and stir for 2-3 Minutes; 0.0017-0.0018 parts of PVA fiber and 0.0043-0.0078 parts of basalt fiber are put into the mixer in sequence and stirred to obtain the concrete.

[0040]In the preparation method of the present invention, the powder and sand are mixed first, and then the water reducing agent is mixed with water before adding, which can improve the mixing uniformity of the concrete. Excellent dispersibility...

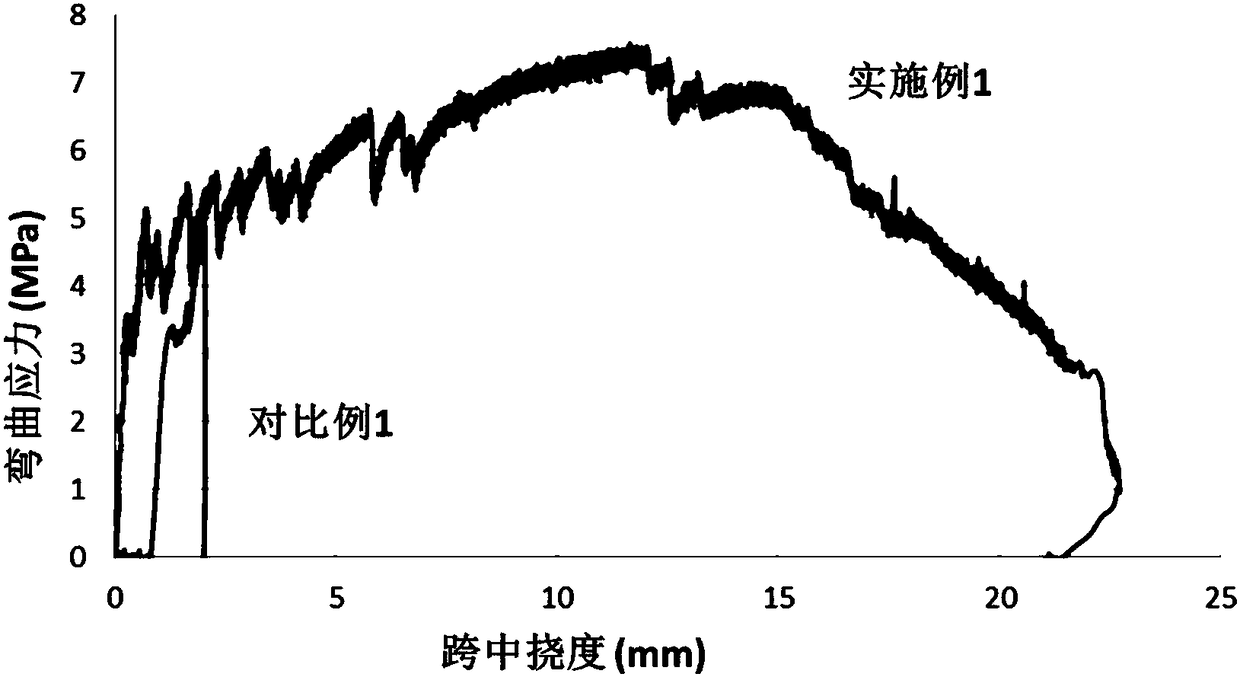

Embodiment 1

[0044] In this embodiment, the PVA-basalt hybrid fiber high-toughness concrete that can be 3D printed is calculated in parts by weight. The composition and content of the concrete are respectively:

[0045] 0.9 parts of rapid hardening ordinary Portland cement;

[0046] F grade fly ash 1.18 parts;

[0047] 0.75 parts of quartz sand, the particle size range of the quartz sand is 0.075-0.15mm;

[0048] 0.32 parts of water;

[0049] 0.006 parts of water reducing agent;

[0050] 0.0017 parts of PVA fiber;

[0051] 0.0043 parts of basalt fiber;

[0052] The specific surface area of the rapid hardening ordinary Portland cement is 348m 2 / kg, the density is 3.0g / cm 3 , the standard consistency water consumption is 25.9%, the initial setting time is 170min, the final setting time is 210min, the loss on ignition is 3.5%, the magnesium oxide content is 2.18%, the 3-day flexural strength is 5.7MPa, and the 3-day compressive strength is 30MPa. The use of rapid hardening cement i...

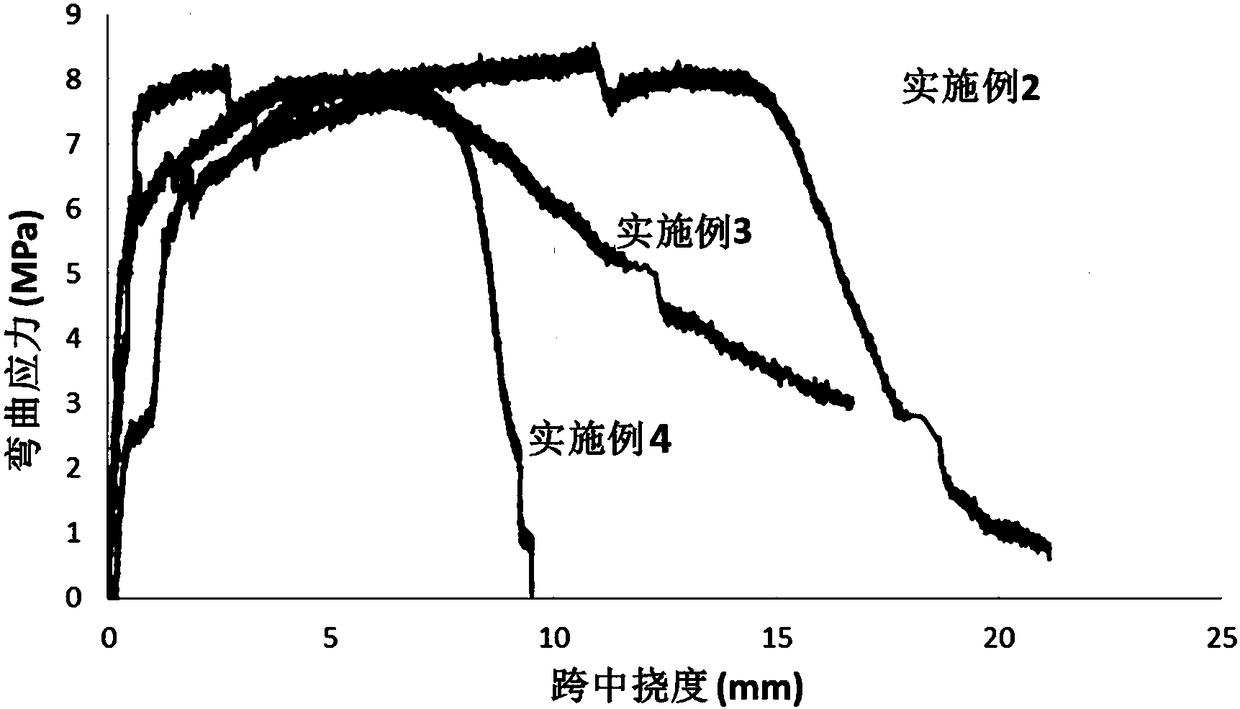

Embodiment 2

[0062] In this embodiment, the PVA-basalt hybrid fiber high-toughness concrete that can be 3D printed is calculated in parts by weight. The composition and content of the concrete are respectively:

[0063] Rapid hardening ordinary Portland cement 1.1 parts;

[0064] F grade fly ash 1.36 parts;

[0065] 0.84 parts of quartz sand, the particle size range of the fine sand is 0.075-0.15mm;

[0066] 0.38 parts of water;

[0067] 0.008 parts of water reducing agent;

[0068] 0.0018 parts of PVA fiber;

[0069] 0.0047 parts of basalt fiber;

[0070] The specific surface area of the rapid hardening ordinary Portland cement is 348m 2 / kg, the density is 3.0g / cm 3 , the standard consistency water consumption is 25.9%, the initial setting time is 170min, the final setting time is 210min, the loss on ignition is 3.5%, the magnesium oxide content is 2.18%, the 3-day flexural strength is 5.7MPa, and the 3-day compressive strength is 30MPa. The use of rapid hardening cement is to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com