Lithionite slag admixture and its preparation method and use

A technology of lepidolite and admixture, applied in the field of building materials, can solve the problems of low comprehensive utilization rate of lithium slag, storage of lithium slag, pollution of the environment, etc. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The admixture preparation technology of green high-performance concrete prepared by lepidolite slag admixture, the specific method is as follows:

[0027] Select corresponding raw materials to prepare lepidolite slag admixture according to the proportioning shown in table A

[0028] Table A Raw material percentage of admixture (%)

[0029] category

Lepidolite slag (%)

Diatomaceous earth (%)

1

100

0

2

97

3

3

95

5

[0030] Preparation of lepidolite slag: industrial waste slag produced by high-temperature calcination of spodumene to produce lithium carbonate, the raw slag has a large water content and serious agglomeration, and its active SiO 2 The content is greater than 70%. First place it in a 105°C drying oven for 24 hours at low temperature to remove free moisture in the lepidolite slag, then take the above-mentioned low-temperature dried lepidolite slag out of the 105°C drying oven, and lightly dry t...

Embodiment 2

[0034] The preparation method of the green high-performance concrete prepared by lepidolite slag admixture, concrete steps are as follows:

[0035] (1) Raw material preparation

[0036] Cement, select commercially available 42.5 grade ordinary Portland cement that meets the national standard; Lepidolite slag admixture, select the admixture obtained by the admixture preparation process described in Example 1 for use, moisture content is less than 1%, ratio The measured surface area is 400~1000m 2 / Kg, equivalent to replace cement, the replacement rate is 0% to 40% of the mass of the cementitious material; coarse and fine aggregates, choose commercially available ones that meet the standards GB / T14685-2011 "Pebbles and gravels for construction" and GB / T14684- 2011 "Sand for Construction" river sand medium sand, fineness modulus 2.8, mud content 0.5% and continuously graded 5-25mm gravel, mud content 1%, washed and dried for later use; efficient water reduction Agent, polycarbo...

Embodiment 3

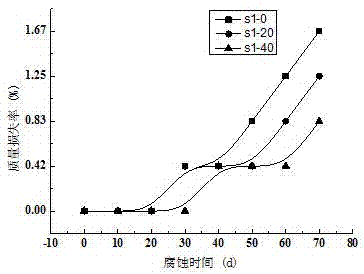

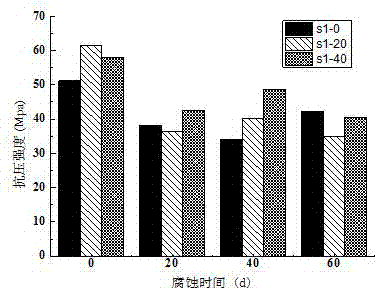

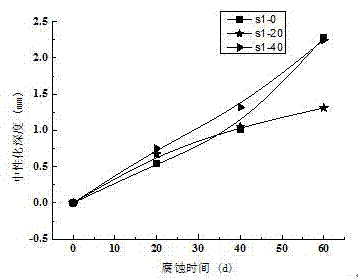

[0051] Durability of green high performance concrete prepared with lepidolite slag admixture:

[0052] (1) Utilize the lepidolite slag admixture obtained by three types of proportions to prepare concrete (W / B=0.4), the amount of lepidolite slag admixture in concrete is 20% of the cementitious material quality, and with different The ordinary concrete containing the admixture of the present invention is used as a comparison specimen to measure the chloride ion penetration resistance, and the results are shown in Table 5.

[0053] Table 5 Chloride ion permeability resistance of green high-performance concrete with lepidolite slag admixture

[0054]

[0055] As can be seen from Table 5, the 6h electric flux<1000 coulombs of the concrete that has been mixed with the lepidolite slag admixture is 27% of the 6h electric flux of the concrete without the admixture of the present invention, and has remarkable chloride ion resistance Permeability, significantly improve the durability...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com