Sound-insulating environment-friendly polypropylene fiber pebble concrete and preparation method thereof

A technology of polypropylene fiber and concrete, which is applied in the field of building materials to achieve strong compressive strength, good heat resistance, and good sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

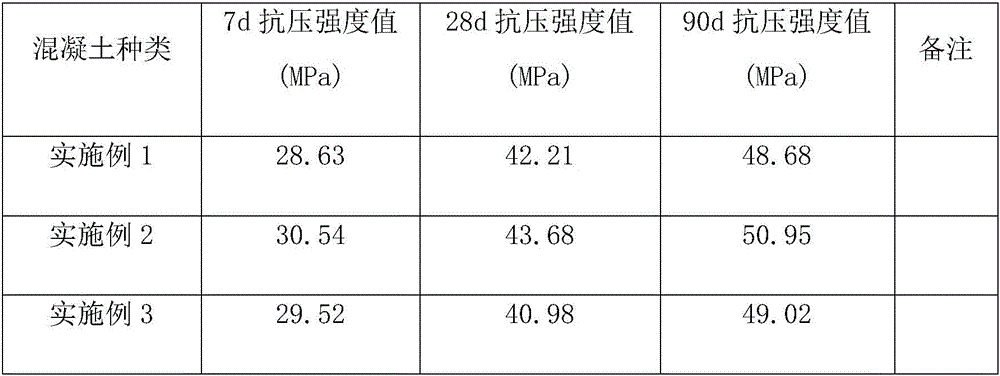

Embodiment 1

[0027] A sound-insulating and environment-friendly polypropylene fiber pebble concrete. The concrete mainly includes the following components: 1200 parts of pebbles, 15 parts of foaming agent, 12 parts of sound-proofing agent, 1.2 parts of polypropylene fiber, 300 parts of cement, and 750 parts of fine aggregate parts, 1.6 parts of high-efficiency water reducer, and 150 parts of water. The preparation method is: first put the fine aggregate, cement, pebbles, foaming agent, sound insulation agent, and high-efficiency water reducer into the forced In a permanent mixer, then disperse the polypropylene fiber of the weight component by hand, add it to the mixer, first let the fine aggregate, cement, pebbles, foaming agent, sound insulation agent, high-efficiency water reducer, polypropylene fiber Dry mix for about 3 minutes, and then add water and wet mix for 3 minutes to prepare the sound-insulating and environment-friendly polypropylene fiber pebble concrete.

[0028] Wherein, th...

Embodiment 2

[0039] A sound-insulating and environmentally friendly polypropylene fiber pebble concrete. The concrete mainly includes the following components: 1250 parts of pebbles, 20 parts of foaming agent, 15 parts of sound-proof agent, 1.35 parts of polypropylene fiber, 325 parts of cement, and 800 parts of fine aggregate parts, 1.7 parts of high-efficiency water reducer, and 175 parts of water. The preparation method is: first put the fine aggregate, cement, pebbles, foaming agent, sound insulation agent, and high-efficiency water reducer into the forced In a permanent mixer, then disperse the polypropylene fiber of the weight component by hand, add it to the mixer, first let the fine aggregate, cement, pebbles, foaming agent, sound insulation agent, high-efficiency water reducer, polypropylene fiber Dry mix for about 3 minutes, and then add water and wet mix for 3 minutes to prepare the sound-insulating and environment-friendly polypropylene fiber pebble concrete.

[0040] Among the...

Embodiment 3

[0051] A sound-insulating and environment-friendly polypropylene fiber pebble concrete. The concrete mainly includes the following components: 1300 parts of pebbles, 25 parts of foaming agent, 18 parts of sound-proofing agent, 1.5 parts of polypropylene fiber, 350 parts of cement, and 850 parts of fine aggregate. parts, 1.8 parts of high-efficiency water reducer, and 200 parts of water. The preparation method is: first put the fine aggregate, cement, pebbles, foaming agent, sound insulation agent, and high-efficiency water reducer into the forced In a permanent mixer, then disperse the polypropylene fiber of the weight component by hand, add it to the mixer, first let the fine aggregate, cement, pebbles, foaming agent, sound insulation agent, high-efficiency water reducer, polypropylene fiber Dry mix for about 3 minutes, and then add water and wet mix for 3 minutes to prepare the sound-insulating and environment-friendly polypropylene fiber pebble concrete.

[0052] Among them...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com