High-performance fibrous concrete of C130 strength level and preparation method thereof

A high-performance fiber, strength grade technology, used in high-performance fiber-reinforced concrete and its preparation, high-toughness and high-durability concrete, high-strength fields, can solve the problems of poor durability, easy cracking, high brittleness, etc., to improve mechanical properties. , the effect of increasing cohesion and inhibiting plastic shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

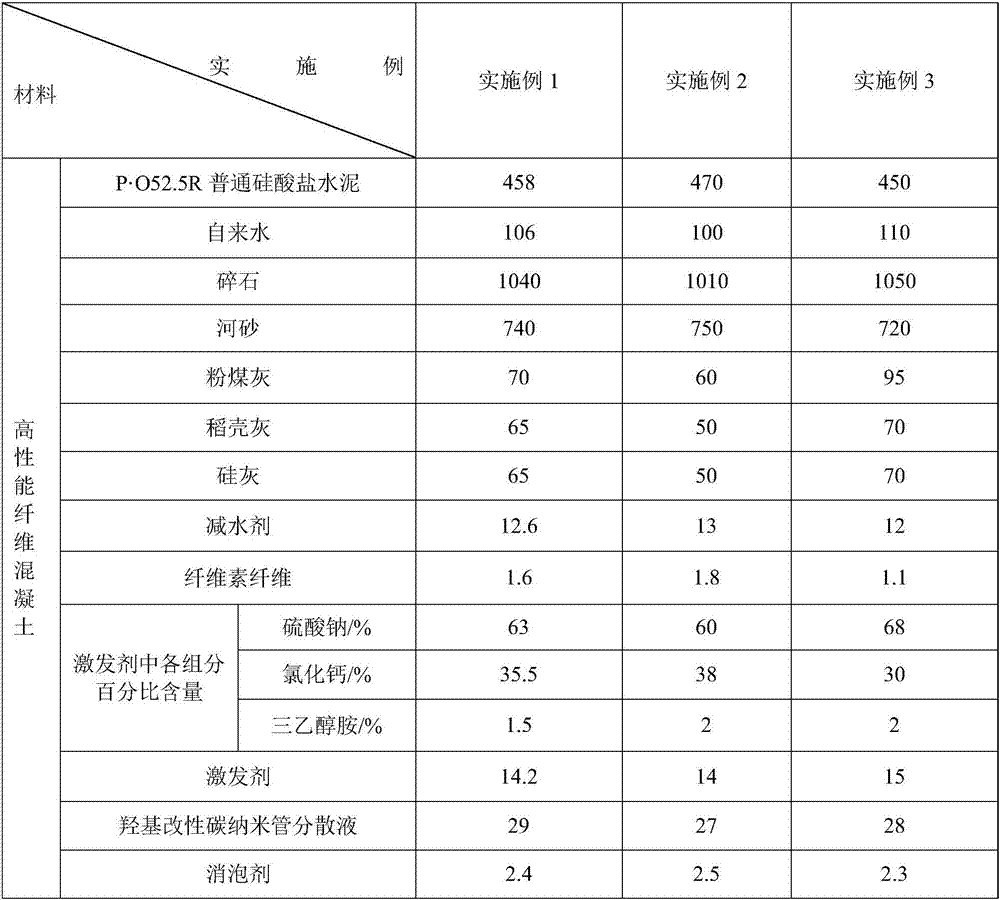

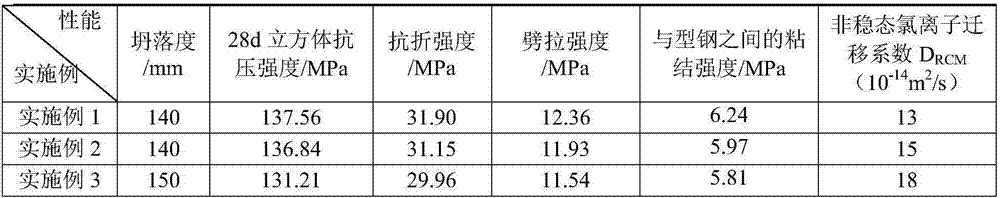

[0041] In the following, the present invention will be further described in detail by using examples in combination with specific embodiments, so as to make the advantages of the present invention easier to be understood by those skilled in the art, but it is not intended to limit the protection scope of the present invention.

[0042] The high-performance fiber concrete of the C130 strength grade of the present invention is prepared by the following method:

[0043] 1) Add 12-13 parts of water reducing agent and 27-29 parts of hydroxyl-modified carbon nanotube dispersion to 25% of the total water, which is recorded as aqueous solution 1; weigh 2.3-2.5 parts of defoamer Added to water with 25% total water content, recorded as aqueous solution 2;

[0044] 2) Add 720-750 parts of river sand, 1010-1050 parts of gravel, and 1.1-1.8 parts of cellulose fiber into the mixer according to the mass ratio, and stir evenly for 2-3 minutes;

[0045] 3) Then, add 450-470 parts of cement, 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com