Basalt fiber recycled insulation concrete and preparation method thereof

A technology of basalt fiber and thermal insulation concrete, which is applied in the field of building materials, can solve the problems of poor performance and low utilization rate of recycled concrete, and achieve the effects of improving durability, delaying concrete performance degradation, and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

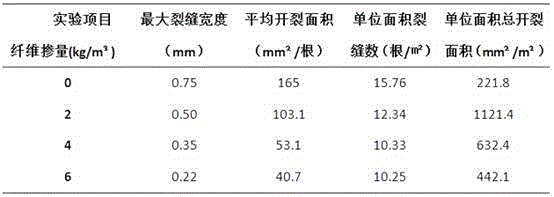

Image

Examples

Embodiment 1

[0036] A basalt fiber recycled thermal insulation concrete, comprising the following raw materials in parts by weight: 605 parts of stones, 605 parts of recycled coarse aggregate, 484 parts of cement, 520 parts of sand, 3 parts of basalt fiber, 150 parts of vitrified microbeads, and external admixtures 5 parts, 2 parts of admixture, appropriate amount of water. Wherein, the fineness modulus of the sand is 2.0-2.4.

[0037] The manufacture method of the basalt fiber recycled thermal insulation concrete comprises the following steps:

[0038] (1) Take a quarter (121 parts) of the above-mentioned weight of cement and an appropriate amount of water (48.4 parts) to prepare cement slurry;

[0039] (2), the basalt fiber of the counterweight is evenly mixed into the cement paste prepared in step (1);

[0040] (3) Add the weighted vitrified microbeads into the mixer and add an appropriate amount of water, and stir for 30s;

[0041] (4) Evenly add the cement slurry evenly wrapped wit...

Embodiment 2

[0045] A basalt fiber recycled thermal insulation concrete, comprising the following raw materials in parts by weight: 363 parts of stones, 848 parts of recycled coarse aggregate, 484 parts of cement, 520 parts of sand, 1 part of basalt fiber, 150 parts of vitrified microbeads, and external admixtures 5 parts, 2 parts of admixture, appropriate amount of water. Wherein, the fineness modulus of the sand is 2.0-2.4.

[0046] The manufacture method of the basalt fiber recycled thermal insulation concrete comprises the following steps:

[0047] (1) Take 1 / 4 of the above-mentioned weight of cement and appropriate amount of water to prepare cement paste;

[0048] (2), the basalt fiber of the counterweight is evenly mixed into the cement paste prepared in step (1);

[0049] (3) Add the weighted vitrified microbeads into the mixer and add an appropriate amount of water, and stir for 30s;

[0050] (4) Add the cement slurry evenly wrapped with basalt fibers prepared in step (2) into t...

Embodiment 3

[0054] A basalt fiber recycled thermal insulation concrete, comprising the following raw materials in parts by weight: 1211 parts of recycled coarse aggregate, 484 parts of cement, 520 parts of sand, 6 parts of basalt fiber, 150 parts of vitrified microbeads, 5 parts of external admixture, and 2 parts of medicine, appropriate amount of water. Wherein, the fineness modulus of the sand is 2.0-2.4.

[0055] The manufacture method of the basalt fiber recycled thermal insulation concrete comprises the following steps:

[0056] (1) Take 1 / 4 of the above-mentioned weight of cement and appropriate amount of water to prepare cement paste;

[0057] (2), the basalt fiber of the counterweight is evenly mixed into the cement paste prepared in step (1);

[0058] (3) Add the weighted vitrified microbeads into the mixer and add an appropriate amount of water, and stir for 30s;

[0059] (4) Add the cement slurry evenly wrapped with basalt fibers prepared in step (2) into the concrete mixer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com