Light high-strength concrete and preparation method thereof

A high-strength concrete and lightweight technology, which is applied in the field of lightweight high-strength concrete and its preparation, can solve the problems of increased bulk density and strength discreteness, decreased concrete strength, and increased concrete bulk density, and achieves excellent work performance, improved hydration activity, and good cohesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

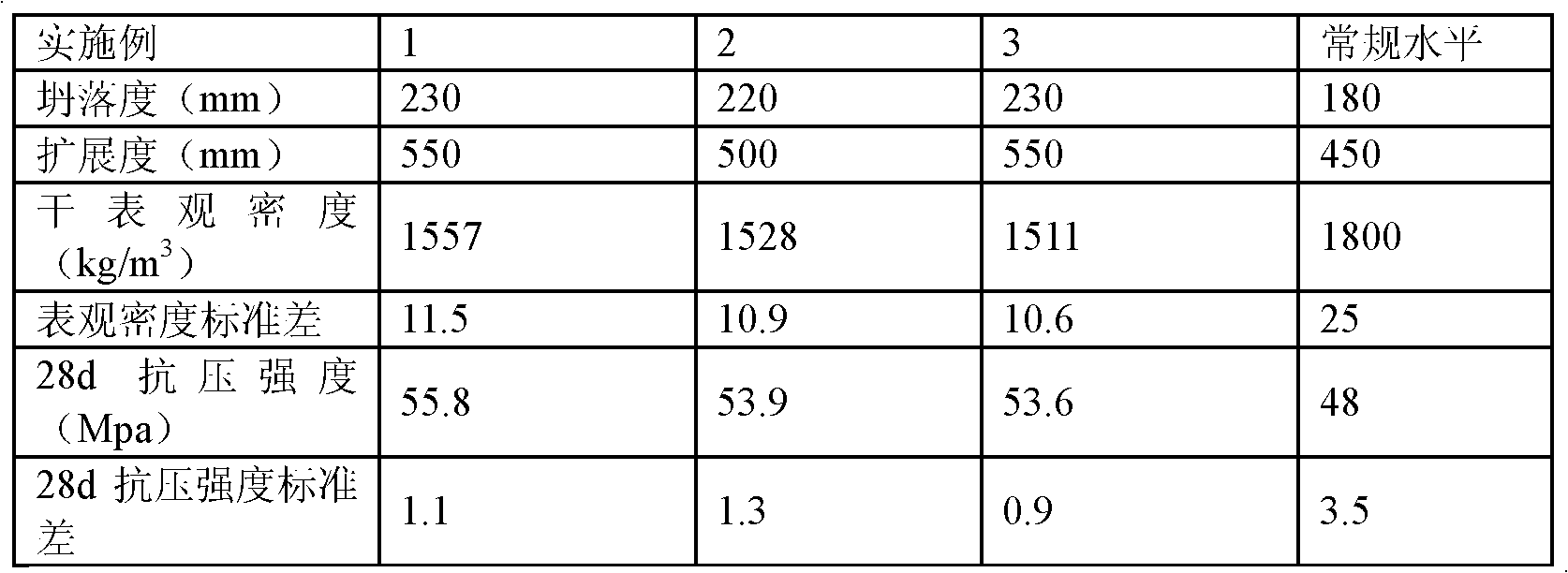

Examples

Embodiment 1

[0026] Embodiment 1: a kind of lightweight high-strength concrete is mainly made of the following raw materials in weight percentage:

[0027] Cementitious material: P·I52.5 cement 12%; mineral powder 8%; fly ash 10%; silica fume 5%; among them, mineral powder, fly ash and silica fume belong to low-density cementitious materials;

[0028] Aggregate: Shale ceramsite 25%; Pottery sand 30%;

[0029] 0.4% of polycarboxylate high-performance water reducer produced by Suzhou Fuke Technology Co., Ltd. (0.2% of model 8H water reducer, 0.2% of model 5H water reducer);

[0030] Activator 0.1% (wherein the mass concentration is 85% triethanolamine 0.05%, the mass concentration is 85% triisopropanolamine 0.03%, analytically pure sodium fluorosilicate 0.02%);

[0031] Hydroxymethyl Cellulose Ether Viscosifier 0.05%,

[0032] Water 9.45%.

[0033] Among the above raw materials, the specific surface area of P·I52.5 cement is 390m 2 / kg, 28d compressive strength 59Mpa; mineral powder is...

Embodiment 2

[0035] Embodiment 2: basically the same as embodiment 1, the difference is the composition of raw materials:

[0036] Cementitious material: P·I52.5 cement 11%; mineral powder 8%; fly ash 8%; silica fume 5%;

[0037] Aggregate: Shale ceramsite 28%; Pottery sand 30%;

[0038] 0.4% of polycarboxylate high-performance water reducer produced by Suzhou Fuke Technology Co., Ltd. (0.2% of model 8H water reducer, 0.2% of model 5H water reducer);

[0039] Activator 0.09% (wherein the mass concentration is 85% triethanolamine 0.05%, the mass concentration is 85% triisopropanolamine 0.02%, analytically pure sodium fluorosilicate 0.02%);

[0040] Hydroxymethyl Cellulose Ether Viscosifier 0.1%

[0041] Water 9.41%.

[0042]The formulation method of the above-mentioned lightweight high-strength concrete is as follows: (1) shale ceramsite with a percentage by weight of 28%; The hydroxymethyl cellulose ether tackifier is added into 1% water by weight, the water temperature is heated to 60...

Embodiment 3

[0043] Embodiment 3: substantially the same as Embodiment 1, the difference is the composition of raw materials:

[0044] Cementitious material: P·I52.5 cement 10%; mineral powder 12%; fly ash 7%; silica fume 6%;

[0045] Aggregate: Shale ceramsite 30%; Pottery sand 25%;

[0046] 0.4% of polycarboxylate high-performance water reducer produced by Suzhou Fuke Technology Co., Ltd. (0.2% of model 8H water reducer, 0.1% of model 5H water reducer, 0.1% of model 9H water reducer);

[0047] Activator 0.14% (wherein the mass concentration is 85% triethanolamine 0.05%, the mass concentration is 85% triisopropanolamine 0.04%, analytically pure diethanolamine 0.03%, analytically pure sodium fluorosilicate 0.02%);

[0048] Polyacrylamide tackifier 0.06%;

[0049] Water 9.4%.

[0050] The formulation method of the above-mentioned lightweight high-strength concrete is as follows: (1) shale ceramsite with a percentage by weight of 30%; The polyacrylamide tackifier is added into 1% water b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com