Magnesium phosphate cement

A technology of magnesium phosphate cement and dihydrogen phosphate, applied in the field of building materials, can solve the problems such as the inability to use it to prepare magnesium phosphate cement with setting time, the setting time of magnesium phosphate cement is difficult to control, the expansion and pulverization of magnesium phosphate cement, and the like. Conducive to the effect of volume stability, high hardness and enhanced compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

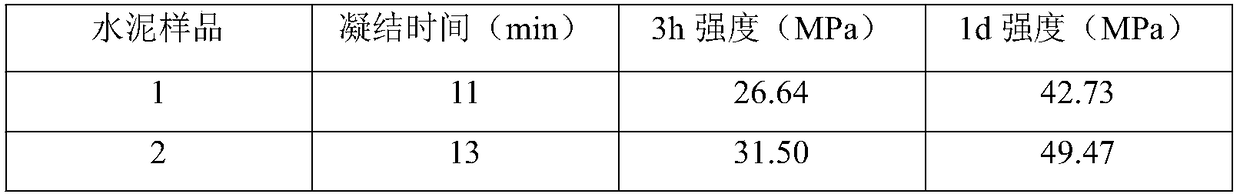

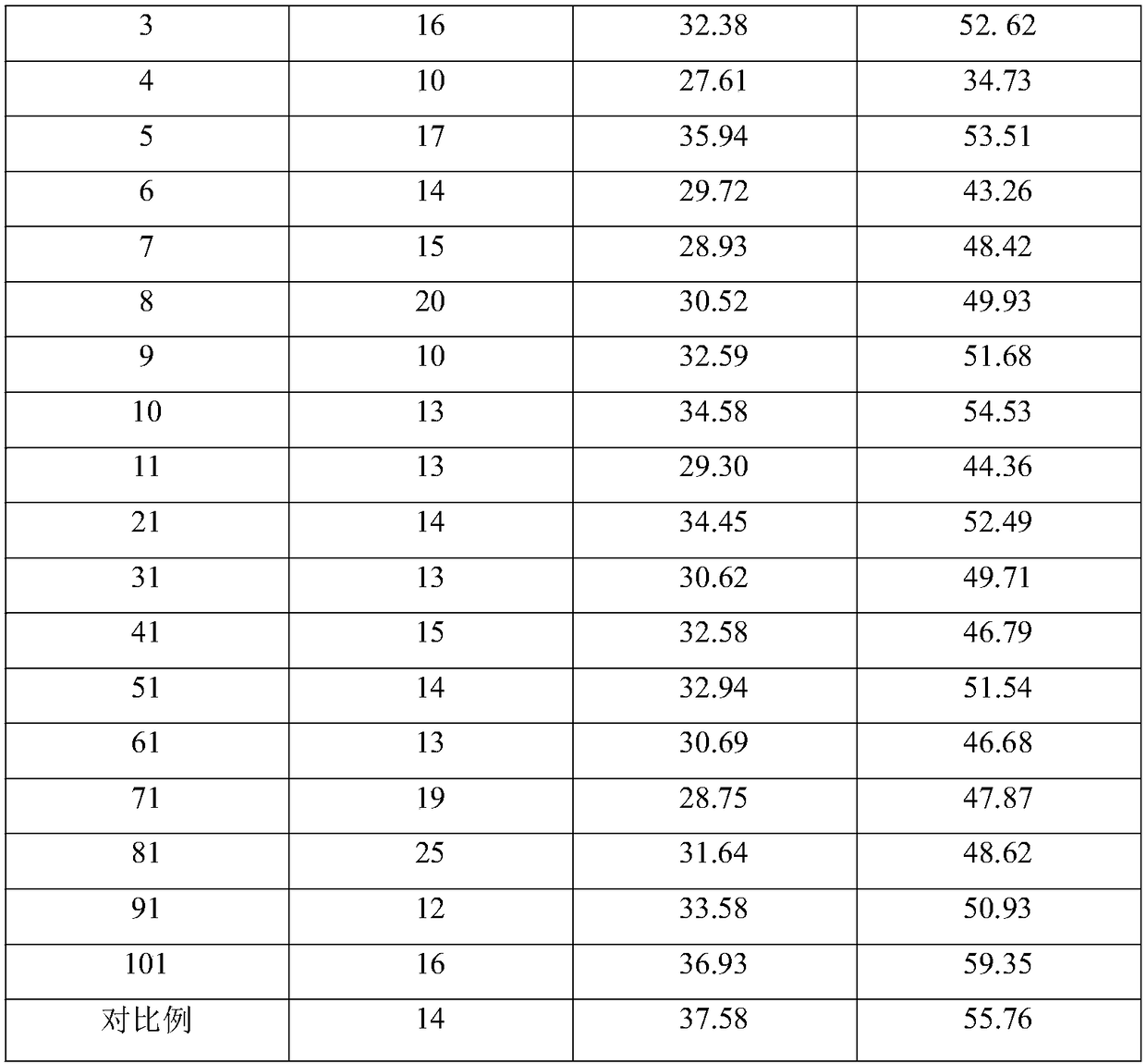

Examples

Embodiment 1

[0027] The preparation method for the calcined dolomite powder that is used to prepare magnesium phosphate cement in the present embodiment may further comprise the steps:

[0028] (1) Dolomite is crushed to below 1mm with a crusher;

[0029] (2) Mix the silica powder and the broken dolomite evenly in a mass ratio of 0.5:1, and the SiO in the silica powder 2 The content is 95%;

[0030] (3) Calcining the above mixture at 1200°C for 1.5h, taking it out and cooling it naturally;

[0031] (4) Grinding the cooled calcined product through a sieve with an aperture of 75 μm to obtain the calcined dolomite powder.

Embodiment 2

[0033] The preparation method for the calcined dolomite powder that is used to prepare magnesium phosphate cement in the present embodiment may further comprise the steps:

[0034] (1) Dolomite is crushed to below 1mm with a crusher;

[0035] (2) Mix silica fume and broken dolomite evenly in a mass ratio of 2:1, and SiO in silica fume 2 The content is 85%;

[0036] (3) Calcining the above mixture at 1300°C for 3h, taking it out and cooling it naturally;

[0037] (4) Grinding the cooled calcined product through a sieve with an aperture of 75 μm to obtain the calcined dolomite powder.

Embodiment 3

[0039] The preparation method for the calcined dolomite powder that is used to prepare magnesium phosphate cement in the present embodiment may further comprise the steps:

[0040] (1) Dolomite is crushed to below 1mm with a crusher;

[0041] (2) Mix silica fume and broken dolomite evenly in a mass ratio of 1:1, and SiO in silica fume 2 The content is 85%;

[0042] (3) Calcining the above mixture at 1600°C for 4h, taking it out and cooling it naturally;

[0043] (4) Grinding the cooled calcined product through a sieve with an aperture of 58 μm to obtain the calcined dolomite powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com