Magnesian concrete damage self-repairing additive and preparation method thereof

A concrete and self-healing technology, applied in the field of building material admixtures, can solve the problems of cracked concrete self-healing without data analysis, cracks being difficult to play a self-healing effect, increasing the strength of anti-crack repairing agents, etc., and reducing hydration. Heat release rate, superior self-healing effect, effect of increasing cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

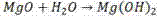

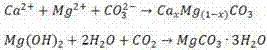

Method used

Image

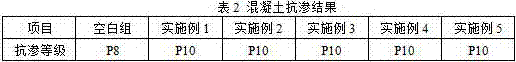

Examples

Embodiment 1

[0048] A kind of magnesia concrete damage self-repairing admixture provided in the present embodiment comprises by weight: 35% of light-burned magnesia, 35% of quartz powder, 10% of kaolin, 5% of sodium silicate, 5% of sodium hexametaphosphate , Gypsum 10%.

Embodiment 2

[0050] A kind of magnesia concrete damage self-repairing admixture provided in the present embodiment comprises by weight: 45% of light-burned magnesia, 35% of quartz powder, 10% of kaolin, 2% of sodium silicate, 3% of sodium hexametaphosphate , gypsum 5%.

Embodiment 3

[0052] A kind of magnesia concrete damage self-repairing admixture provided in the present embodiment comprises by weight: 55% of light-burned magnesium oxide, 25% of quartz powder, 10% of kaolin, 2% of sodium silicate, 3% of sodium hexametaphosphate , gypsum 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com