A high-strength corrosion-resistant titanium-steel composite pipe and its production process

A composite pipe and corrosion-resistant technology, applied in the field of composite pipes, can solve the problems affecting the interface bonding quality of composite materials, over-melting, cost reduction, etc., and achieve excellent fusion infiltration effect, reduce deformation rate, and reduce the effects of deformation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

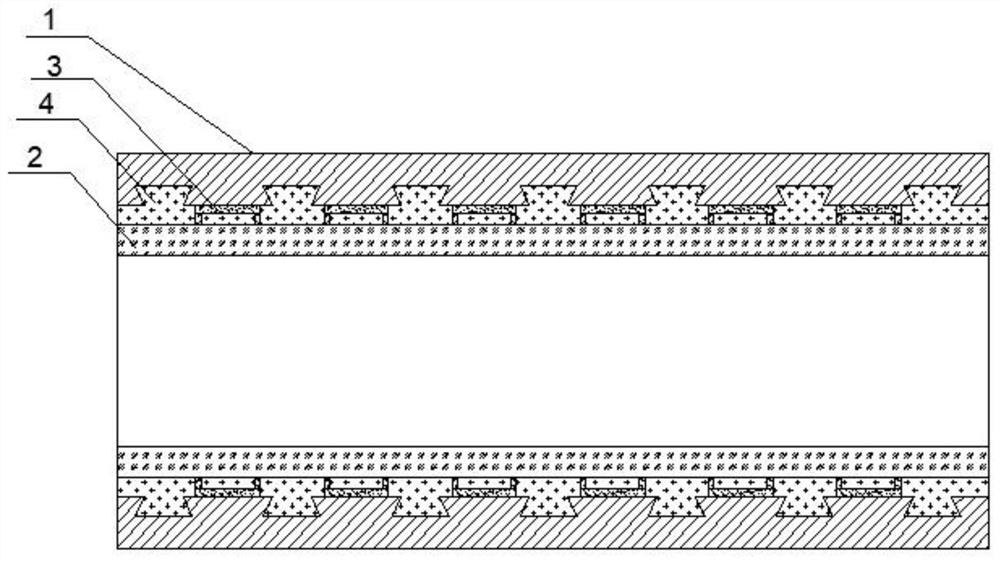

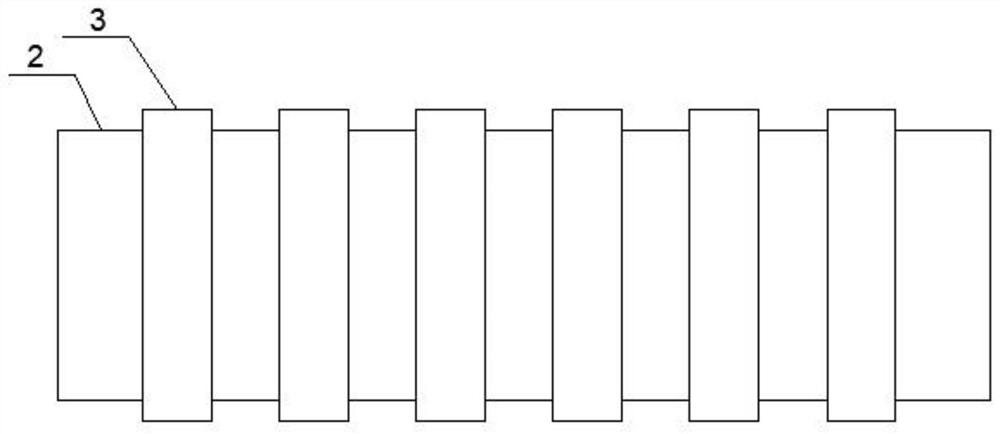

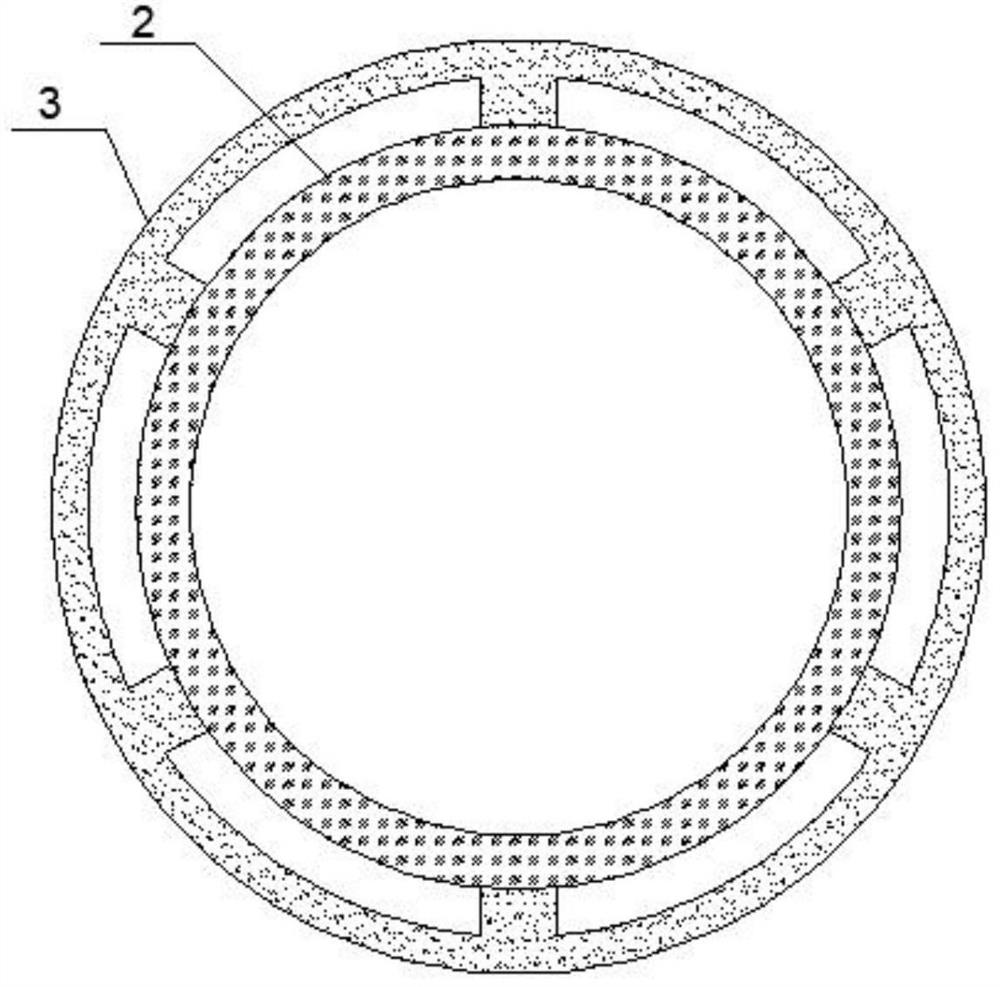

[0032] A high-strength corrosion-resistant titanium-steel composite pipe, such as Figures 1 to 3 As shown, it includes an outer steel pipe 1 and an inner titanium pipe 2, the two are coaxially socketed, the inner wall of the steel pipe 1 is provided with a number of slots, the outer wall of the titanium pipe 2 is fixed with a number of rib assemblies 3, and the rib assembly 3 The outer wall is in interference fit with the inner wall of the steel pipe 1, and the inner wall of the steel pipe 1 and the outer wall of the titanium pipe 2 are filled with an alloy layer 4;

[0033] The alloy layer is made of nickel-based alloy, and the content of nickel in the nickel-based alloy is >90wt%. -0.5%, Fe<0.05%, C<0.1%, boron fiber 0.5-1.5%;

[0034] The cross-section of the slot is a trapezoidal structure (or fan-shaped structure or multi-layer ladder shape, which is not specifically limited here, and the contact area in the slot can be gradually increased from the outside to the inside...

Embodiment 2

[0038] The production process of high-strength and corrosion-resistant titanium-steel composite pipe includes the following steps:

[0039] 1) Take the steel pipe and the titanium pipe, carry out surface treatment on the steel pipe and the titanium pipe, then perform groove processing on the inner surface of the steel pipe, weld the rib assembly on the outer wall of the titanium pipe, and then carry out surface treatment on the steel pipe and the titanium pipe again;

[0040] 2) inserting the titanium tube into the steel tube, forming an interference fit through a drawing machine, the outer diameter of the rib assembly on the titanium tube is larger than the inner diameter of the steel tube, and the interference is 6-6.5%, and a composite tube blank is obtained;

[0041] 3) Cover both ends of the composite tube blank with the processed annular steel plate with reserved injection holes, then weld the two ends of the composite tube blank, inject molten alloy fluid between the com...

Embodiment 3

[0046] With reference to the pipeline structure of embodiment 1, the production process of embodiment 2, carry out specific operation;

[0047] A 304n stainless steel tube with an outer diameter of Φ100mm, a wall thickness of 8mm, and a length of 3m, and a TA2 titanium tube with an outer diameter of Φ80mm, a wall thickness of 5mm, and a length of 2.85m are selected as the composite outer tube and inner tube respectively;

[0048] The alloy layer is made of nickel-based alloy, the content of nickel element is >90wt%, and the nickel-based alloy includes the following element components in weight percentage: Cu 1.5%, Cr 4.7%, Nb 0.4%, Ta 0.3%, Fe 0.022%, C 0.06 %, boron fiber 1.1%.

[0049] In the metal injection molding technology, the loading of nickel-based alloy powder is 56.2vt%, the filler is paraffin or a mixture of paraffin and polyethylene glycol with a volume ratio of 5:1, the filler dosage is 36.5vt%, and the surfactant is stearic acid , the amount of surfactant is 7....

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com