Substrate preparation method, substrate structure, chip packaging method and chip packaging structure

A technology for substrate preparation and chip packaging, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve the problem of easily damaged chip conductive lines, affecting the yield of chip packaging structure, and difficulty in opening depth. control issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] The chip packaging method of this embodiment includes the following steps:

[0083] S10. Prepare the first sub-substrate:

[0084] S10a, providing a first glass substrate 11, pasting a first photosensitive dry film on one side of the first glass substrate 11, forming several windows after exposure and development;

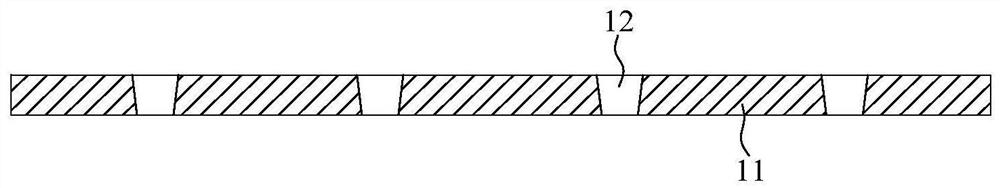

[0085] S10b, opening a TGV through hole 12 for the first glass substrate 11 in the window, refer to figure 1 ;

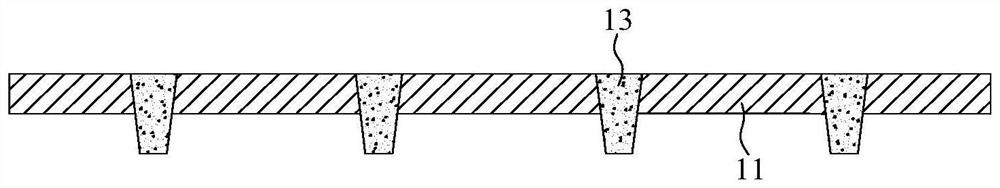

[0086] S10c, making the conductive column 13 in the TGV through hole 12, and making one end surface of the conductive column 13 flush with the surface of the first glass substrate 11, and making the other end surface of the conductive column 13 protrude from the first glass substrate 11 forming the boss, refer to figure 2 ;

[0087] S10d, removing the remaining first photosensitive dry film.

[0088] S20. Prepare the second sub-substrate:

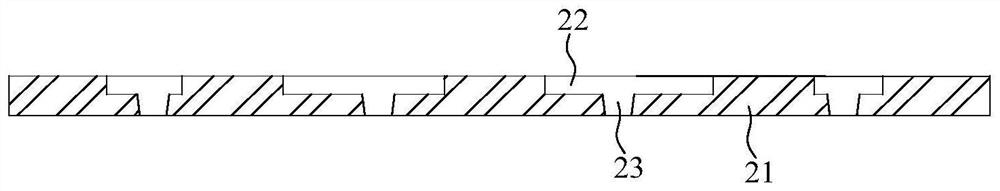

[0089] S20a, provide the second glass substrate 21 with the same thickness as the length of the boss,...

Embodiment 2

[0120] The chip packaging method of this embodiment is basically the same as that of the first embodiment above (for the drawings, refer to the drawings in the first embodiment above, and the same components use the same reference numerals), the difference lies in step S20a and step S30:

[0121] S20a, provide the second glass substrate 21, design the opening area of the circuit groove 22 and the opening position of the via hole 23 in the circuit groove 22 according to the position of the circuit of the first redistribution layer 24 and the conductive column 13, and then carry out laser focus modification After modification, ammonium bifluoride solution is used for soaking to etch the laser focus modification area, so that a circuit groove 22 is opened on the side of the second glass substrate 21 and a line groove through the second glass is opened in the circuit groove 22. The via hole 23 of the substrate 21 .

[0122] S30. Attaching the first sub-substrate to the second su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com