Core-shell type particle as well as preparation method and application thereof

A technology of core-shell type and particles, which is applied in the field of core-shell particles and its preparation, which can solve the problem of unstable improvement of the crack resistance of cement-based materials, the inability to significantly improve the crack resistance of cement-based materials, and the crack resistance of cement-based materials Improve the stability of the interface bonding, the effect of flexible deformation energy absorption is significant, and the crack resistance performance is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

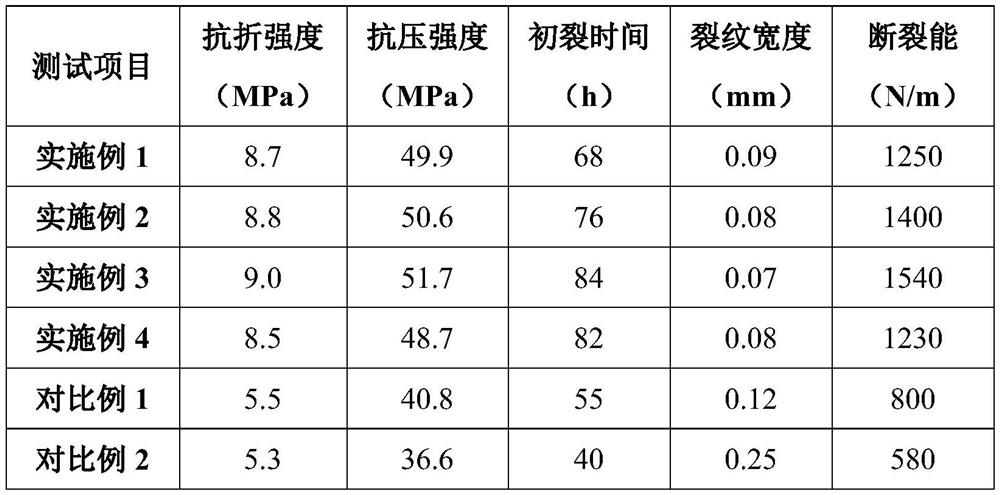

Examples

Embodiment 1

[0044] A core-shell particle, its preparation method comprises the following steps:

[0045] 1) Mix 10 parts by mass of gelatin (number-average molecular weight is 35000 g / mol), 0.2 parts by mass of dicyclopentadienyl acrylate and 10 parts by mass of deionized water (conductivity is less than 0.5us / cm), at 50° C. Stirring at constant temperature for 2 h to obtain a hydrogel precursor;

[0046] 2) adding 10 mass parts of zeolite particles (particle diameter is less than 50 μm, median particle diameter is 30 μm) into 50 mL of sodium acetate solution with a concentration of 0.5 mol / L, stirring for 15 min, then microwave heating for 10 min, microwave power is 343W, naturally Cooling, then washing with water, suction filtration and drying (to constant weight) to obtain modified zeolite particles;

[0047] 3) The modified zeolite particles were added to the hydrogel precursor, stirred for 6 hours, and then the gelled modified zeolite particles were soaked in 40 mL of a tannin solut...

Embodiment 2

[0051] A core-shell particle, its preparation method comprises the following steps:

[0052] 1) Mix 15 parts by mass of gelatin (number average molecular weight is 50000g / mol), 0.28 parts by mass of glutaraldehyde and 10 parts by mass of deionized water (conductivity is less than 0.5us / cm), and stir at a constant temperature for 3h at 55°C , to obtain a hydrogel precursor;

[0053] 2) adding 10 mass parts of zeolite particles (particle diameter is less than 50 μm, and median particle diameter is 35 μm) into the sodium chloride solution that the concentration of 50 mL is 1.0 mol / L, stirred for 25 min, and then microwaved for 20 min, and the microwave power was 350W, Natural cooling, washing with water, suction filtration and drying (to constant weight) to obtain modified zeolite particles;

[0054] 3) The modified zeolite particles were added to the hydrogel precursor, stirred for 6 hours, and then the gelled modified zeolite particles were soaked in 35 mL of tannin solution w...

Embodiment 3

[0058] A core-shell particle, its preparation method comprises the following steps:

[0059] 1) Mix 5 parts by mass of gelatin (number average molecular weight is 80000g / mol), 0.35 parts by mass of dicyclopentadienyl acrylate and 10 parts by mass of deionized water (conductivity is less than 0.5us / cm), at 65° C. Stirring at constant temperature for 2 h to obtain a hydrogel precursor;

[0060] 2) adding 10 mass parts of zeolite particles (particle diameter is less than 50 μm, and median particle diameter is 28 μm) into the lithium chloride solution that the concentration of 30 mL is 3.0 mol / L, stirring for 15 min, and then microwave heating for 15 min, and the microwave power is 343W, Natural cooling, washing with water, suction filtration and drying (to constant weight) to obtain modified zeolite particles;

[0061] 3) The modified zeolite particles were added to the hydrogel precursor, stirred for 6 h, and then the gelled modified zeolite particles were soaked in 30 mL of a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com