Device and method for dry-method treatment for and sensible heat recovery of high-temperature molten slag

A technology of dry processing and waste heat recovery device, which is applied in waste heat treatment, energy efficiency improvement, lighting and heating equipment, etc., and can solve problems such as complex equipment structure, waste heat recovery rate to be improved, and high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

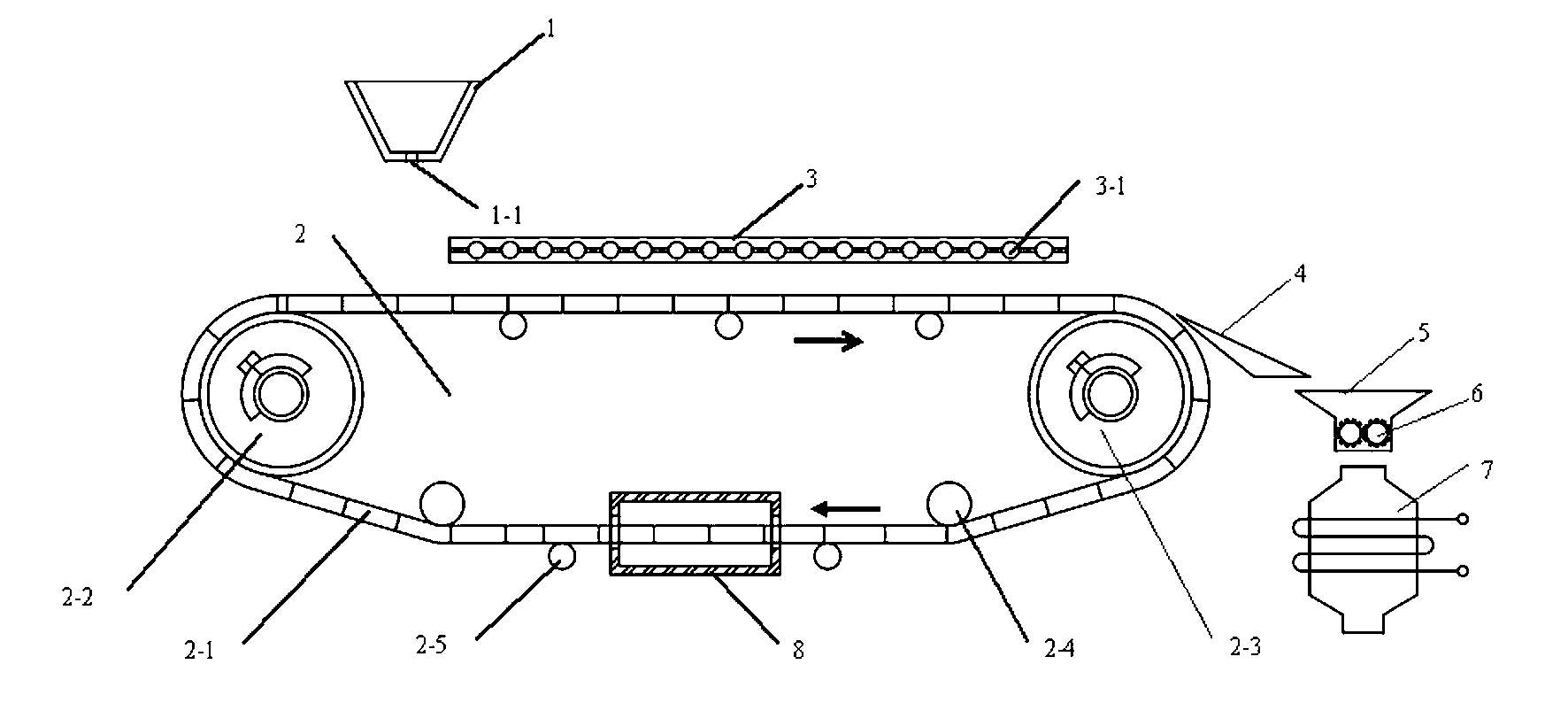

[0038] The device structure for dry treatment of high temperature slag and recovery of sensible heat is as follows: figure 1 As shown, it includes a grate 2, a water wall 3, a slag scraper 4, a slag collector 5 and a waste heat recovery device 7; wherein the first drive sprocket 2-2 of the grate 2 is located under the tundish 1, The water wall 3 is located above the grate plate 2-1, there is a gap between one end of the slag scraper 4 and the grate 2-1 above the second driving sprocket 2-3, and slag particles are arranged under the other end of the slag scraper 4 The collector 5 and the bottom of the slag collector 5 are provided with a roller crusher 6, and a waste heat recovery device 7 is provided below the roller crusher 6; the waste heat recovery device 7 is a solid particle waste heat boiler, and the cooling medium is water;

[0039] A cooling water channel 3-1 is provided in the water cooling wall 3, and the distance between the water cooling wall 3 and the grate plate ...

Embodiment 2

[0052] The device structure for dry processing of high-temperature slag and recovery of sensible heat is the same as that of Example 1, except that:

[0053] (1) The waste heat recovery device is a fixed bed, and the cooling medium is air;

[0054] (2) The distance between the water wall and the grate plate is 500mm;

[0055] (3) The thickness of the grate plate is 150mm;

[0056] (4) The width of the strip-shaped opening of the tundish is 200mm, and the ratio of the length to the width of the grate plate is 0.82:1;

[0057] The method of high-temperature slag dry processing and reclaiming sensible heat is the same as embodiment 1, and the difference is:

[0058] (1) Granular slag is formed after being pulverized into the fixed bed, and normal temperature air is passed into the fixed bed to exchange heat with the granular slag, forming hot air to absorb heat, and the granular slag is discharged after waste heat recovery; 8.1x10 5 m 3 / h;

[0059] (2) The thickness of th...

Embodiment 3

[0063] The device structure for dry processing of high-temperature slag and recovery of sensible heat is the same as that of Example 1, except that:

[0064] (1) The waste heat recovery device is a fluidized bed, and the cooling medium is air;

[0065] (2) The distance between the water wall and the grate plate is 200mm;

[0066] (3) The thickness of the grate plate is 30mm;

[0067] (4) The width of the strip-shaped opening in the tundish is 60mm, and the ratio of the length to the width of the grate plate is 0.92:1;

[0068] The method of high-temperature slag dry processing and reclaiming sensible heat is the same as embodiment 1, and the difference is:

[0069] (1) Granular slag is formed into the fluidized bed after being pulverized, and normal temperature air is passed into the fluidized bed to exchange heat with the granular slag, forming hot air to absorb heat, and the granular slag is discharged after waste heat recovery; The input amount is 4.1x10 6 m 3 / h;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com