Compound gel material special for marine concrete, production method and application thereof

A composite cementitious material and production method technology, applied in the field of building materials, can solve the problems of long-term and durable adverse effects of hardened concrete, uneven concrete mixture, insufficient mixing time, etc., and achieve the mechanical properties of slurry and chlorine resistance Improved ion erosion performance, high hydration activity, and increased density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

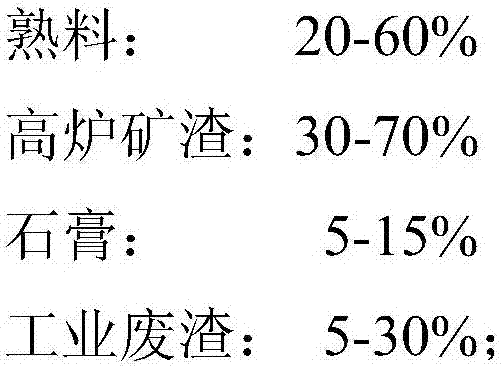

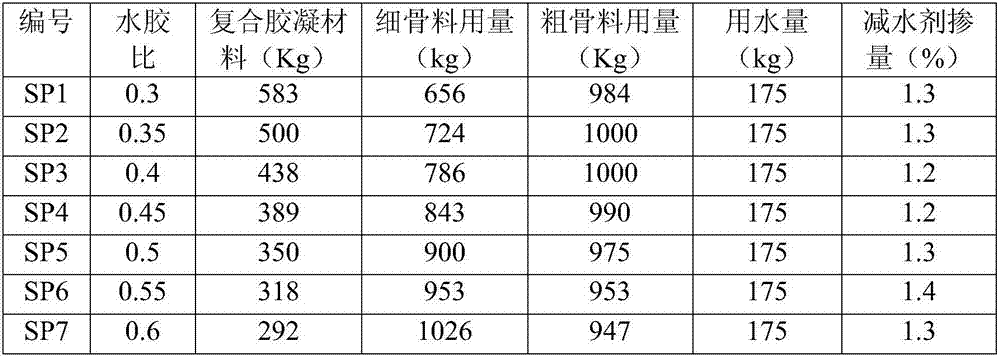

[0033] According to the ratio of two groups of composite cementitious materials as described in Table 1, mix and grind the clinker, gypsum and industrial waste according to the ratio until the specific surface area is 350m 2 / kg, grind the slag to a specific surface area of 450m 2 / kg, the two are mixed evenly to prepare two kinds of composite gelling materials.

[0034] Table 1 Proportion of composite cementitious materials

[0035]

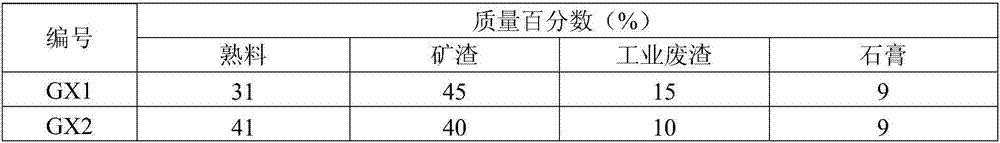

[0036] The above two composite cementitious materials were used to prepare concrete according to different water-binder ratios, and the specific mixes are shown in Table 2.

[0037] Table 2 concrete mix ratio

[0038]

[0039] Table 3 shows the performance index and mechanical performance index of the concrete mixture prepared according to the formula in Table 1 and Table 2.

[0040] Table 3 The performance index and mechanical performance index of the prepared concrete mixture

[0041]

[0042] The data in Table 3 shows that conc...

Embodiment 2

[0044] In order to further compare the performance of the concrete prepared with the above two composite cementitious materials, a comparative test was carried out using the mix ratio of a key project of marine concrete constructed by a large state-owned enterprise in China. The test plan is shown in Table 4. The performance comparison of concrete Table 5 shows.

[0045] Table 4 Concrete mix ratio comparison test plan for a key project in China

[0046]

[0047] Table 5 Comparison of concrete mechanical properties and anti-chloride ion erosion performance

[0048]

[0049] The data in Table 5 shows that, under the condition that the proportion of sand and gravel, the ratio of water to cement, the total amount of cementitious material, and the properties of the controlled concrete mixture are all the same, they are all three components, and the composite cementitious material is used as the single cementitious material. The 3d strength of the concrete prepared by the mater...

Embodiment 3

[0051] In order to further determine the advantages of the special composite cementitious material for marine concrete proposed by the present invention, a domestic naval base key project marine concrete mix ratio was selected and a comparative test was carried out. The test scheme is shown in Table 6, and the performance comparison of concrete is shown in Table 7. Show.

[0052] Table 6 Comparison test plan of marine concrete mix ratio in a naval base

[0053]

[0054] Table 7 Comparison of concrete mechanical performance indicators and chloride ion corrosion resistance

[0055]

[0056] The data in Table 7 shows that the 3d strength of concrete prepared using the composite cementitious material of the present invention as a single cementitious material is nearly 6-14MPa higher than that of concrete prepared by conventional methods, and the 28d strength is at most 4-8MPa higher. Simultaneously, the electric flux of the concrete prepared by using the composite cementiti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com