Preparation method of aluminum oxide porous material

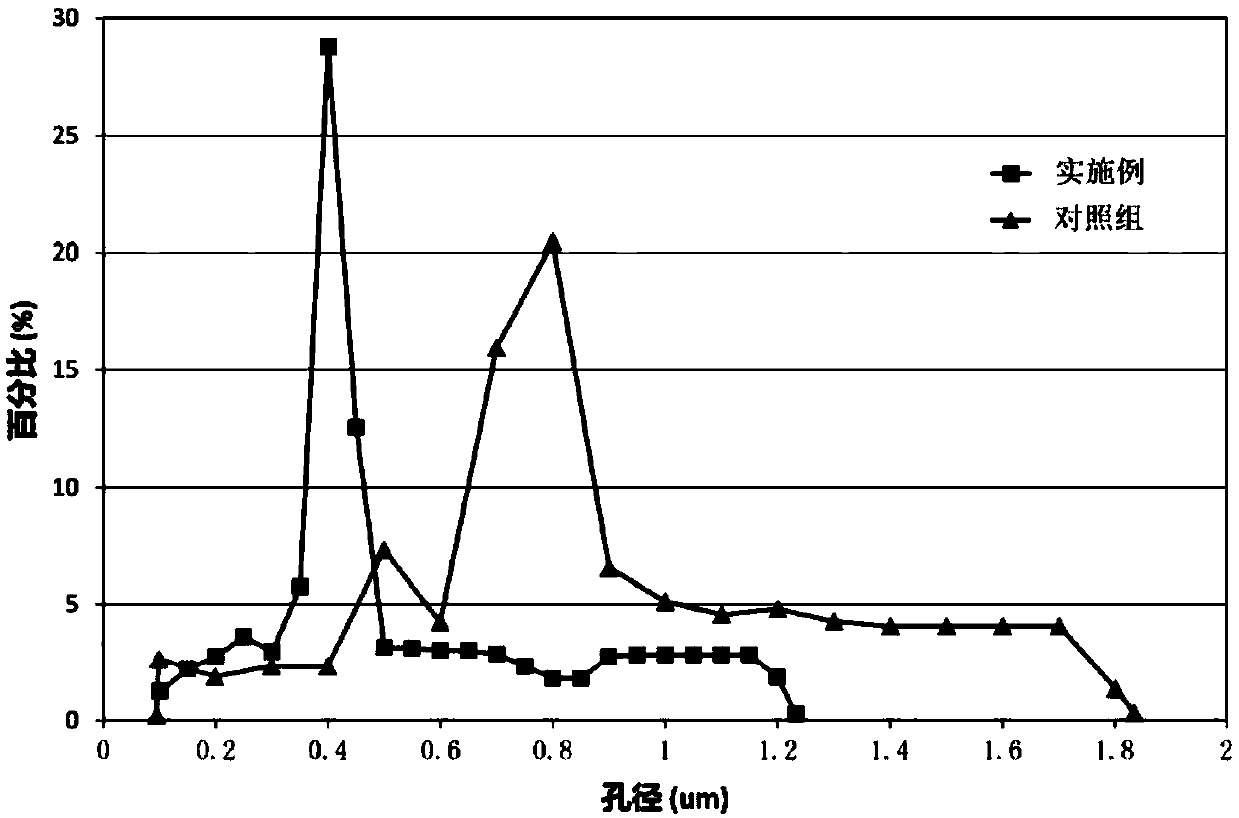

A technology of porous materials and alumina, which is applied in the field of preparation of alumina porous materials, can solve the problems of widening pore size distribution and reducing porosity, and achieve the effects of improving rheology, increasing hydrophilicity, and improving the quality of green bodies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this example 1, the α-alumina powder with an average particle size of 18 μm is used as the raw material for preparing porous alumina materials, and the following steps and formulas are used to prepare alumina porous materials or produce alumina porous material products.

[0026] (1) prepare magnesium phosphate sol: add 200g phosphoric acid in reactor, the mass concentration of described phosphoric acid is 50%, start stirring, and add 50g light magnesium oxide powder in reactor, reactor is heated to 50 ℃, After the reactant forms a transparent sol, stop heating and stirring;

[0027] (2) Carry out particle modification treatment on alumina powder: put 50kg of alumina powder into a ball mill tank, add 15kg of water and 250g of magnesium phosphate sol, and ball mill to mix, then put the obtained alumina slurry in 80- Dry at 90°C to obtain modified alumina powder;

[0028] (3) Prepare alumina porous material aggregate: add 50 g of manganese oxide micropowder to the modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com