Laser additive repairing method for H13 steel mold

A laser additive and repair method technology, applied in additive processing, process efficiency improvement, additive manufacturing, etc., can solve the problems of large thermal influence, large heat input, long manufacturing cycle, etc., and achieve high hardness and impact toughness , reduce internal cracks and maintain uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

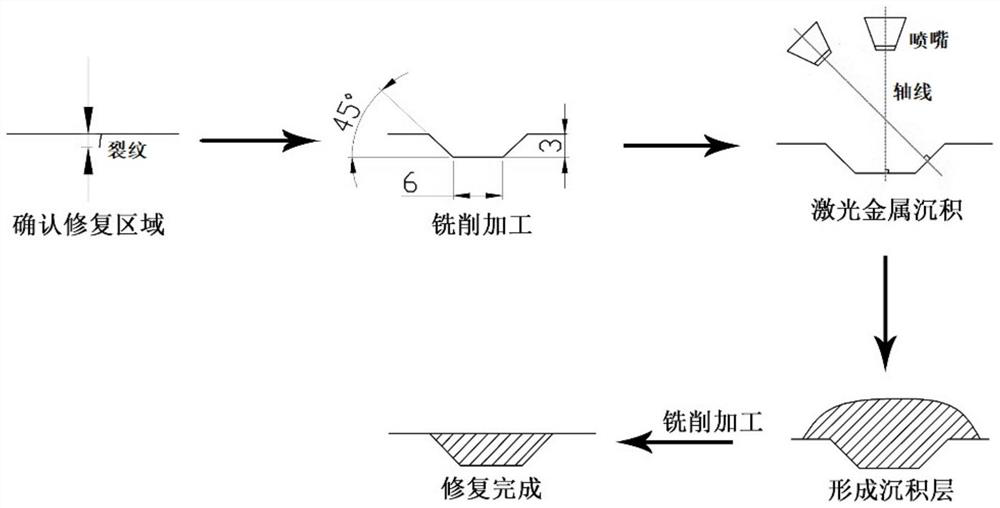

[0047] A kind of laser additive repairing method of H13 steel mould, it comprises the following steps (process flow chart as figure 1 shown):

[0048] 1) Determine the area to be repaired of the H13 steel mold. The area to be repaired is flat and has microcracks with a depth of 1 mm. First, the H13 steel that is 2 mm below the bottom of the area to be repaired and 3 mm outside the center is removed by milling, and the area to be repaired is processed into trapezoidal groove, and then use 400# sandpaper to grind the milling area to a surface roughness Ra value of 3.2, and then clean the milling area with absolute ethanol;

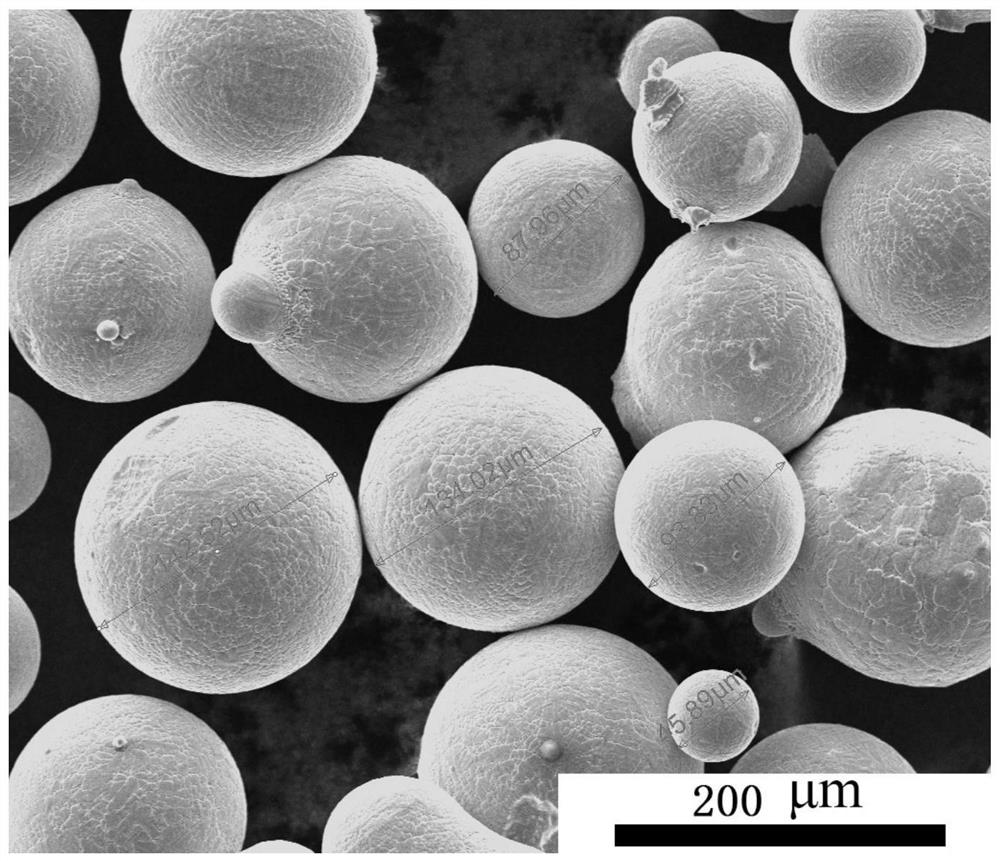

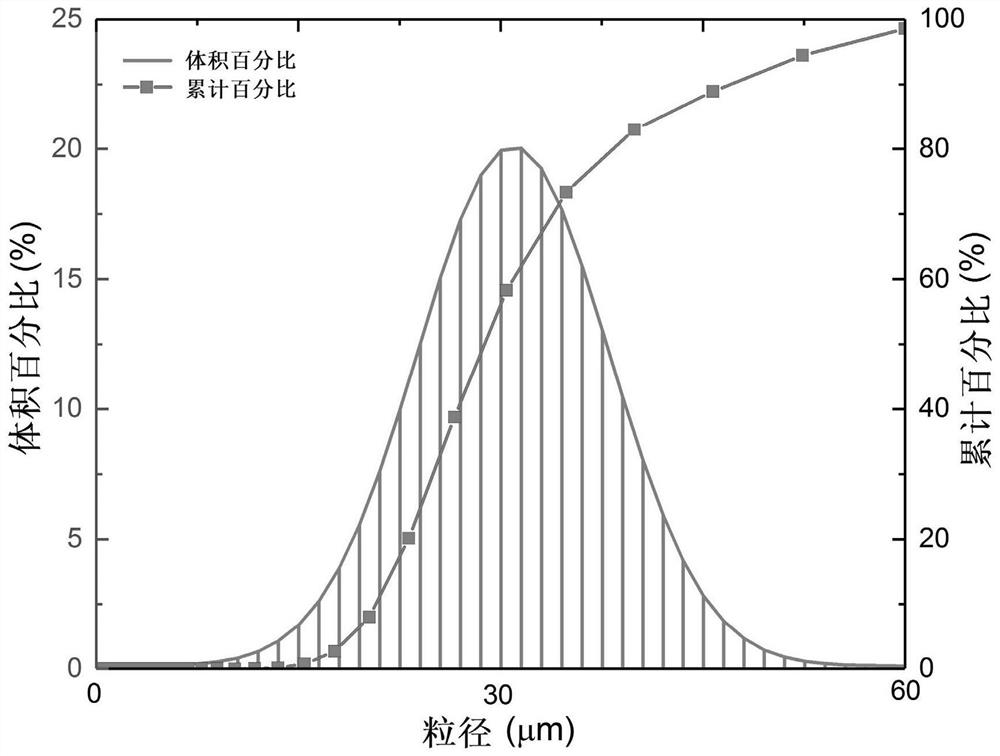

[0049] 2) Spherical H13 steel mixed powders with different particle size distribution were prepared by aerosol method (scanning electron microscope picture as figure 2 shown), the mass percentages of spherical H13 steel mixed powders with different particle size distributions are: C: 0.32% to 0.45%; V: 0.80% to 1.20%; Cr: 4.75% to 5.50%; Mo: 1.10% to 1.75%...

Embodiment 2

[0058] A kind of laser additive repairing method of H13 steel mould, it comprises the following steps (process flow chart as Figure 7 shown):

[0059] 1) Determine the area to be repaired of the H13 steel mold. The area to be repaired is a curved surface, and there are microcracks with a depth of 3 mm. First, remove the H13 steel 2 mm below the bottom of the area to be repaired and 3 mm outside the center by milling, and process the area to be repaired into Arc groove, and then use 400# sandpaper to grind the milling area to a surface roughness Ra value of 3.2, and then clean the milling area with absolute ethanol;

[0060] 2) Spherical H13 steel mixed powders with different particle size distributions were prepared by aerosol method. The element mass percentages of the spherical H13 steel mixed powders with different particle size distributions were: C: 0.32%-0.45%; V: 0.80%-1.20%; Cr: 4.75% to 5.50%; Mo: 1.10% to 1.75%; Mn: 0.20% to 0.50%; Si: 0.80% to 1.20%; P: 0.03%; Fe:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com