Patents

Literature

51 results about "Laser metal deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser metal deposition is a generative manufacturing method for metals. Internationally, it is generally known as "laser metal deposition", abbreviated to LMD.

Manufacturable geometries for thermal management of complex three-dimensional shapes

Uniform cooling of complex surface shapes in injection mold tooling can be accomplished with cooling channels that conform to the shapes of the mold cavity or mold cone. By conventional methods this can be very difficult to accomplish. By applying methods of material deposition or material sintering, which include but are not limited to, laser metal deposition, where material is deposited on a layer by layer basis, certain cooling or heating passages could be integrated into the manufactured component that follow the contours and profiles of the mold's complex surfaces. These passages would act as internal heat sinks with a much higher surface area for heat transfer than traditional drilled and plugged straight passages. These geometries could also be incorporated into complex geometries such as, but not limited to, turbine blades where the cooling passages can follow the contour of the outer shape, provide a more uniform or controlled heat transfer from the component. Multiple loops of cooling or heating channels could be designed and manufactured into solid objects for small-scale heat exchanger technologies.

Owner:OPTOMEC DESIGN CO

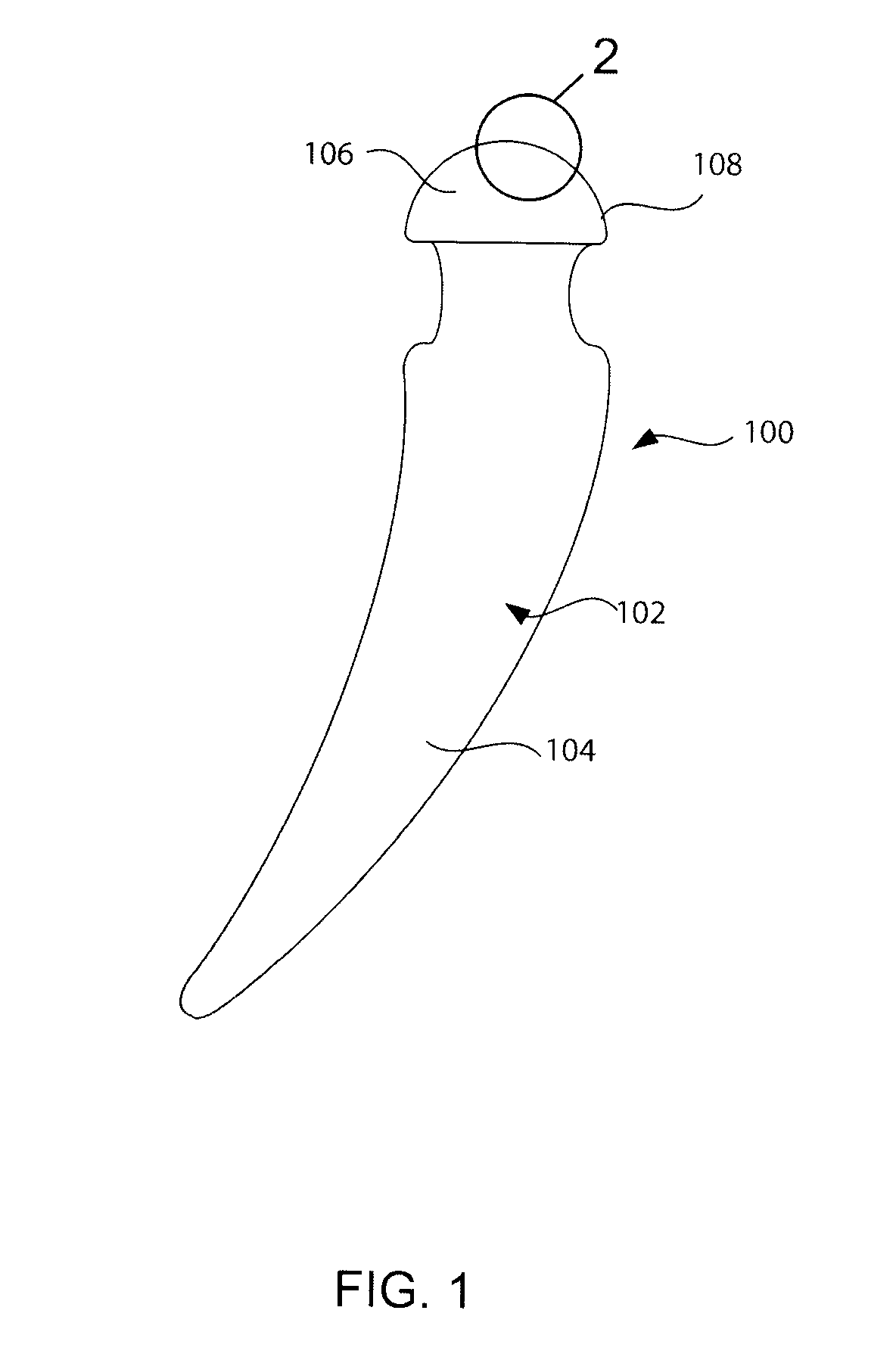

Laser based metal deposition (LBMD) of antimicrobials to implant surfaces

InactiveUS20070287027A1Improved bearing propertyImprove propertiesFinger jointsDental implantsWear resistantBearing surface

A method is provided for depositing a hard wear resistant surface onto a porous or non-porous base material of a medical implant. The wear resistant surface of the medical implant device may be formed by a Laser Based Metal Deposition (LBMD) method such as Laser Engineered Net Shaping (LENS). The wear resistant surface may include a blend of multiple different biocompatible materials. Further, functionally graded layers of biocompatible materials may be used to form the wear resistant surface. Usage of a porous material for the base may promote bone ingrowth to allow the implant to fuse strongly with the bone of a host patient. The hard wear resistant surface provides device longevity, particularly when applied to bearing surfaces such as artificial joint bearing surfaces or a dental implant bearing surfaces. An antimicrobial material such as silver may be deposited in combination with a metal to form an antimicrobial surface deposit.

Owner:MEDICINELODGE

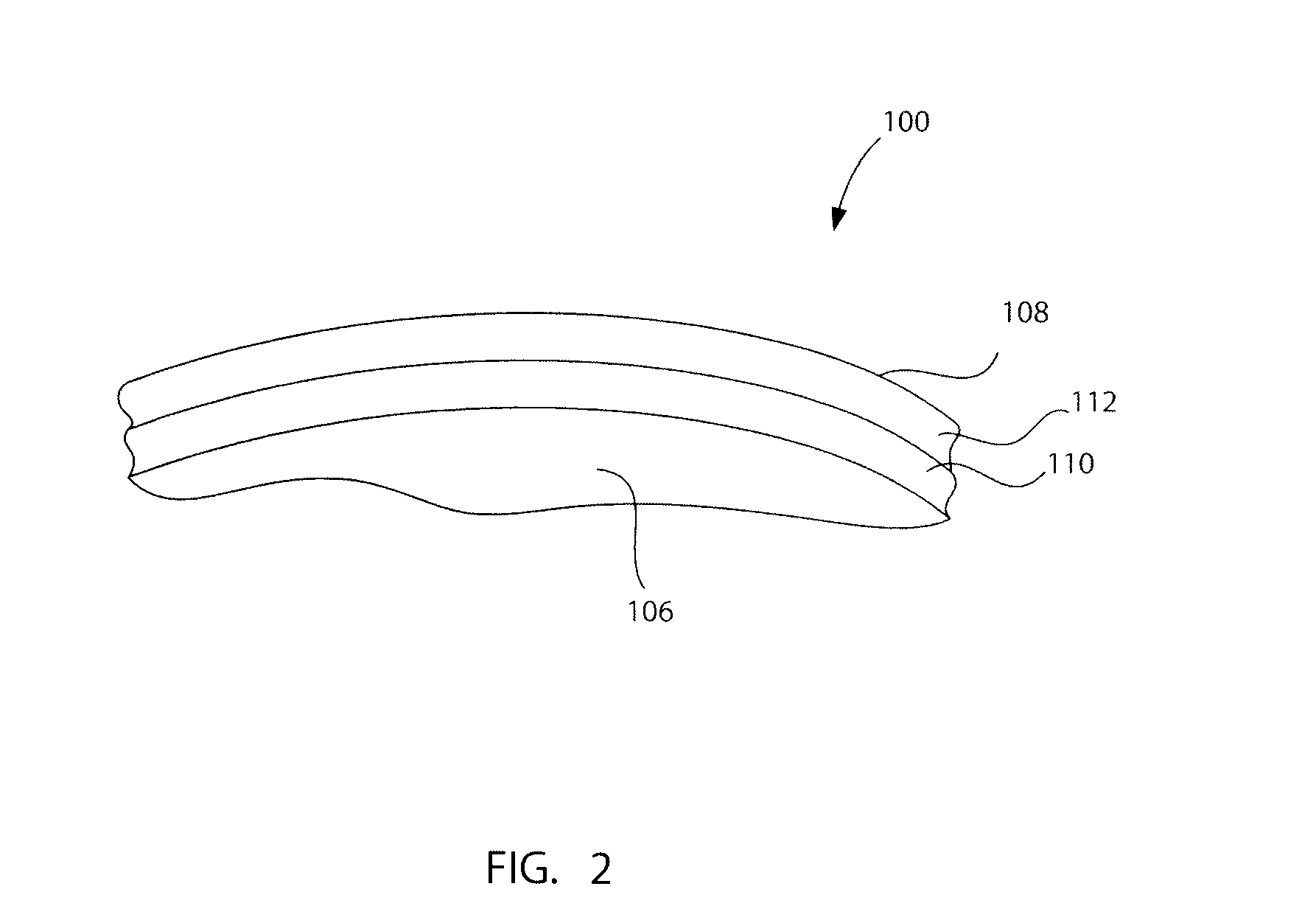

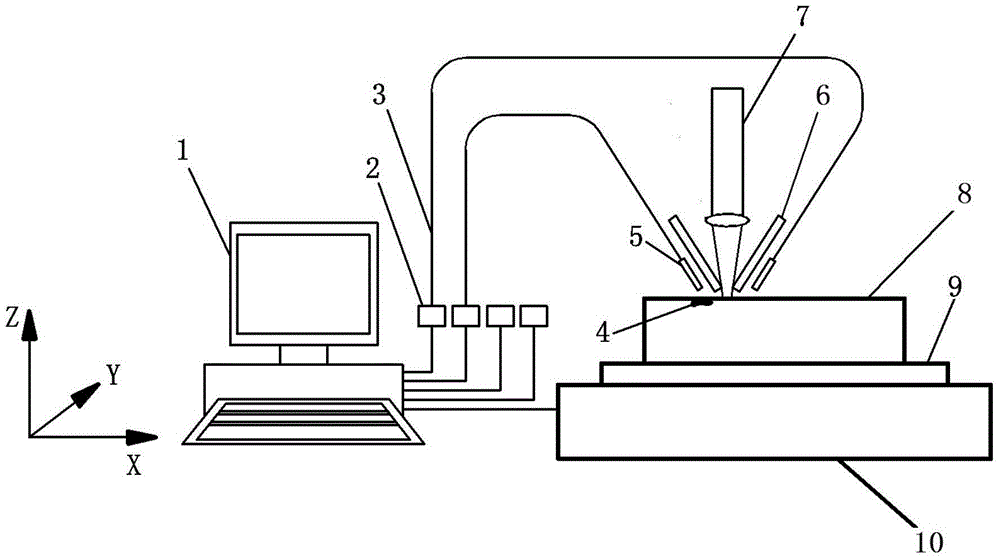

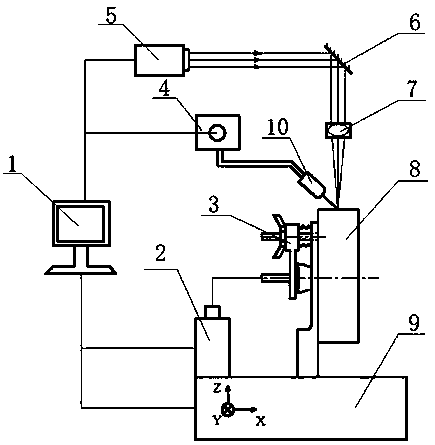

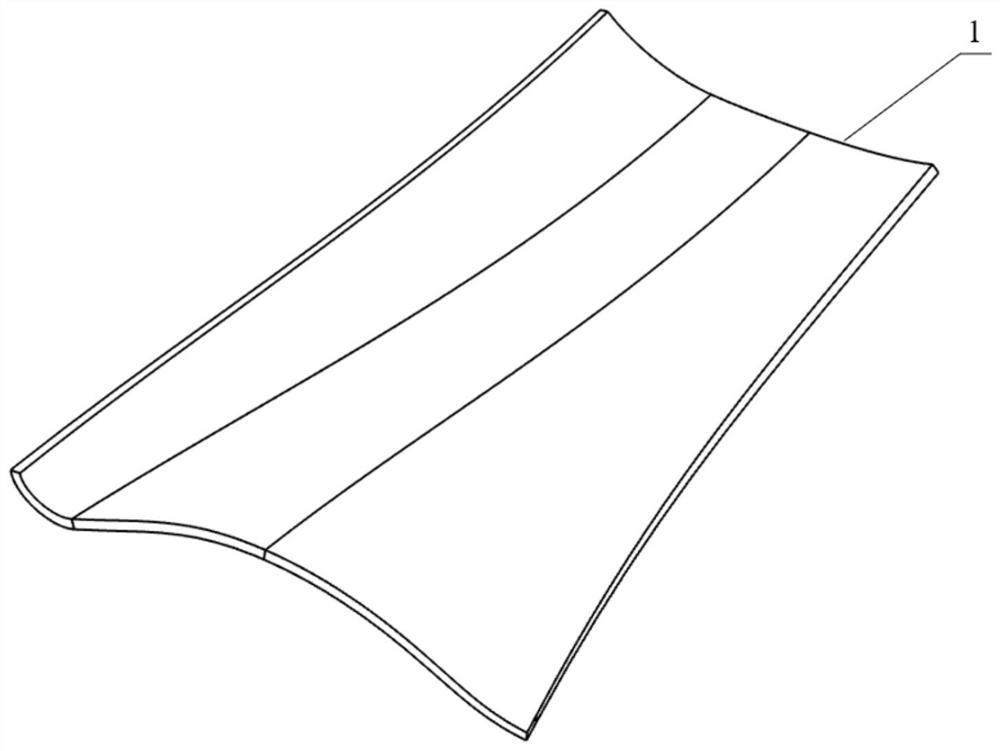

Complicated thin-walled workpiece formation system and method based on progressive formation and additive manufacturing

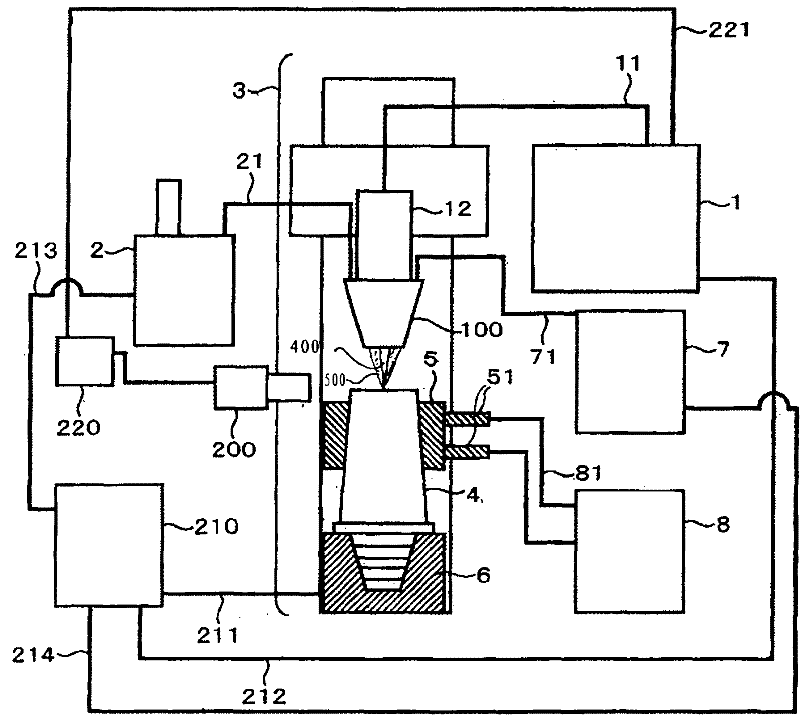

InactiveCN106311876AImprove sustainabilityEfficient preparationAdditive manufacturing apparatusIncreasing energy efficiencyControl systemSpray nozzle

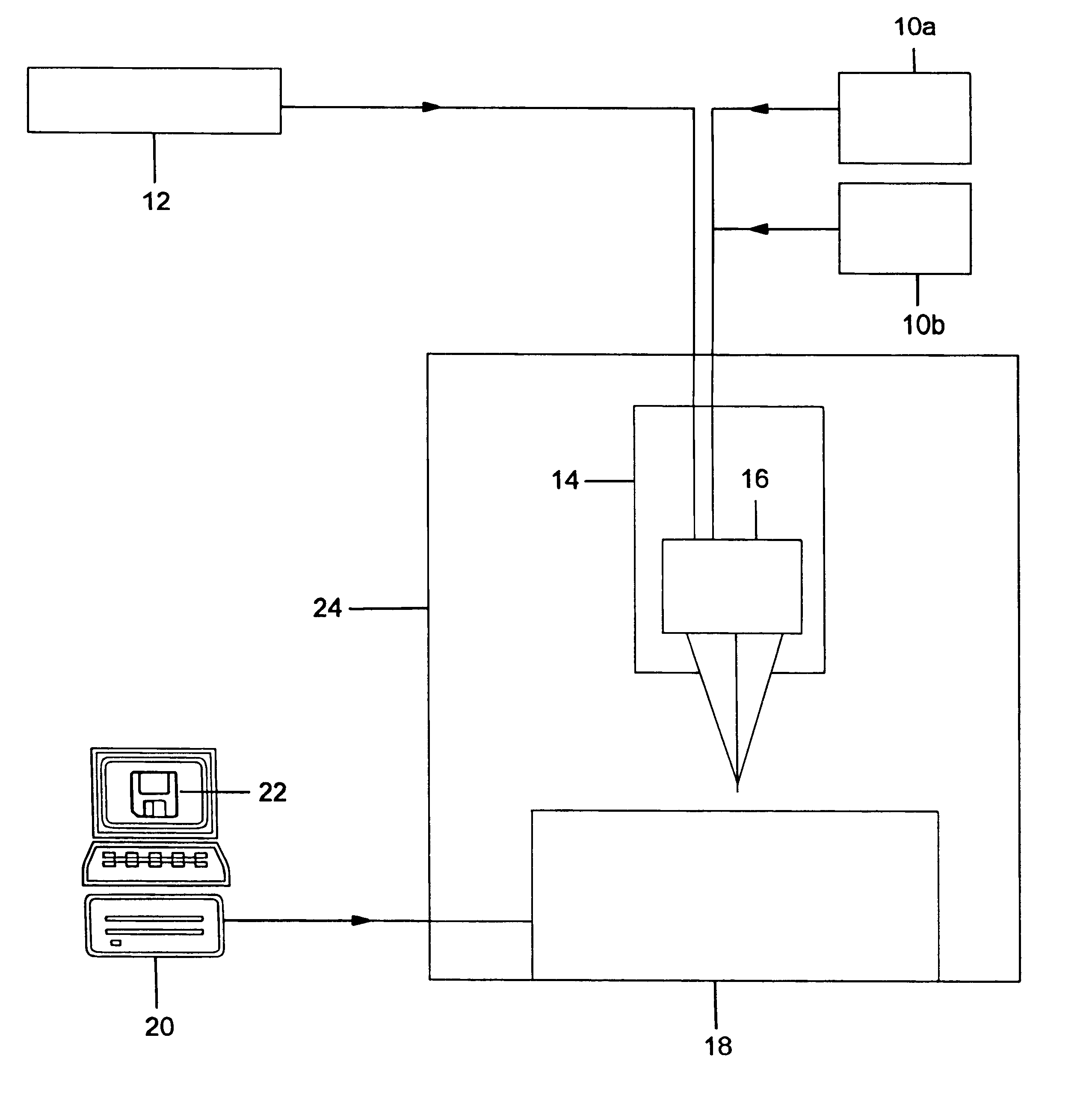

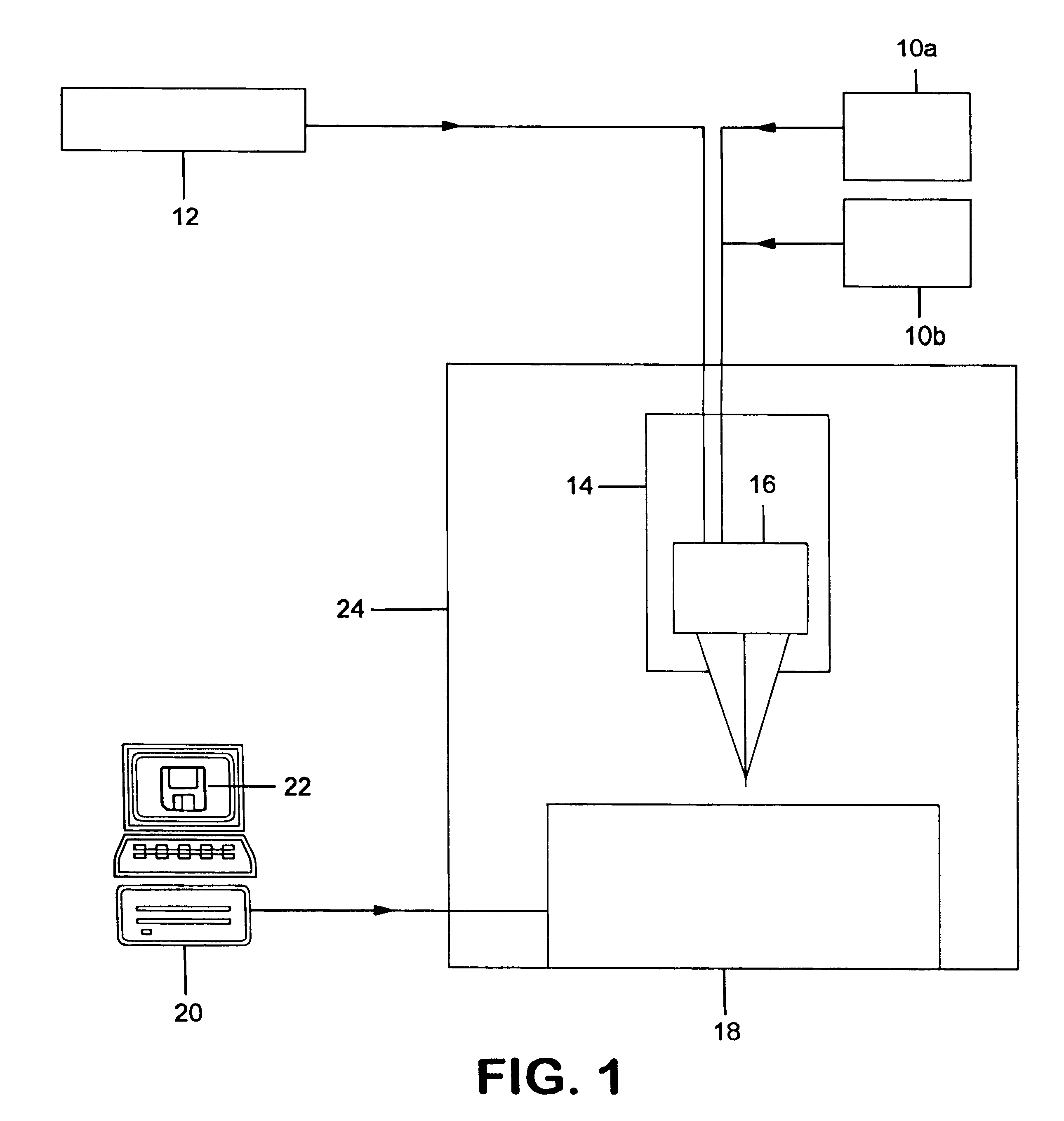

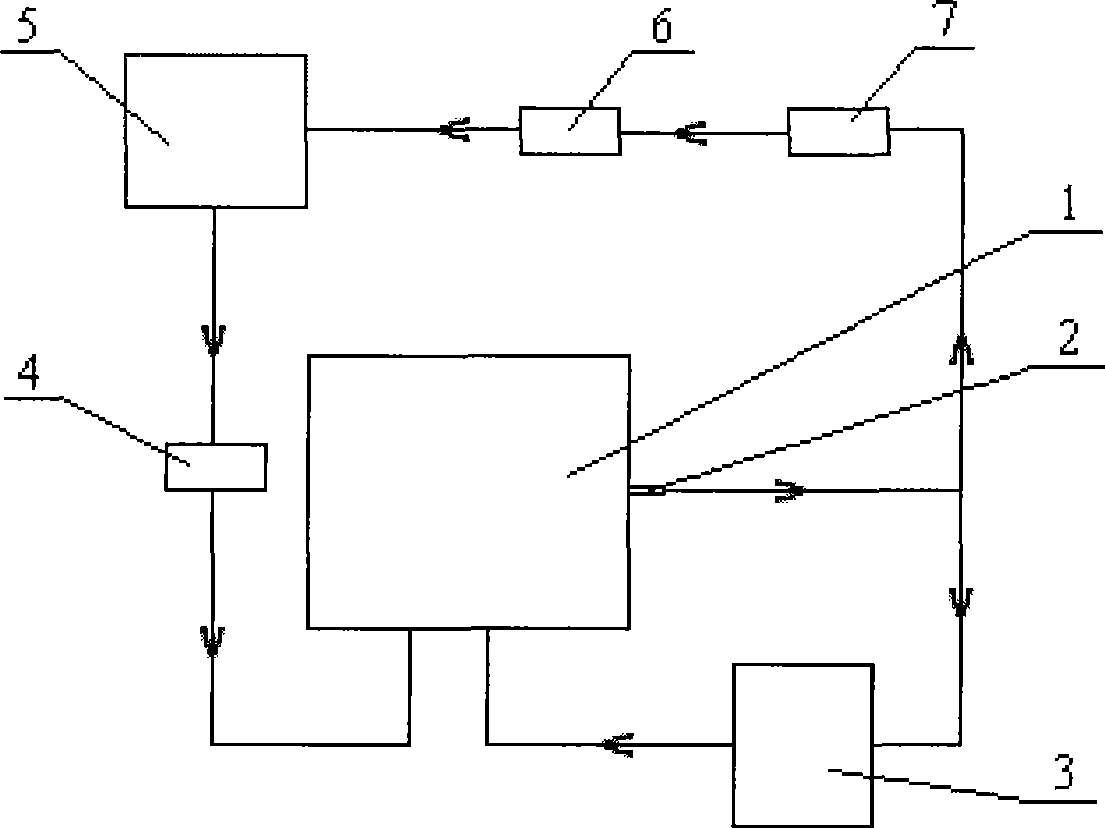

Disclosed is a complicated thin-walled workpiece formation system and method based on progressive formation and additive manufacturing. The system comprises a progressive forming system, a laser metal deposition system and a control system. The progressive forming system comprises a worktable, a three-dimensional movement platform and an electric spindle, wherein the electric spindle is mounted on the three-dimensional movement platform and provided with a tool bit, and the worktable is arranged below the electric spindle and provided with a clamp. The laser metal deposition system comprises a fiber laser, a laser head, a powder feeder and a nozzle. The formation method is to clamp the plate to the fixture of the worktable, the control system controls the electric spindle to drive the tool bit to form the sheet layer by layer and to form the thin-walled shell; and then through laser, metal powder is fused and deposited on the thin-walled shell, and the block-type characteristics are formed. The complicated thin-walled workpiece formation system can realize the small batch and efficient manufacture of the complicated thin-walled workpiece, and has the advantages of saving material, and eliminating the need of mold and the like, and the manufacturing cycle of the complicated thin-walled workpiece is shortened.

Owner:SHANDONG UNIV

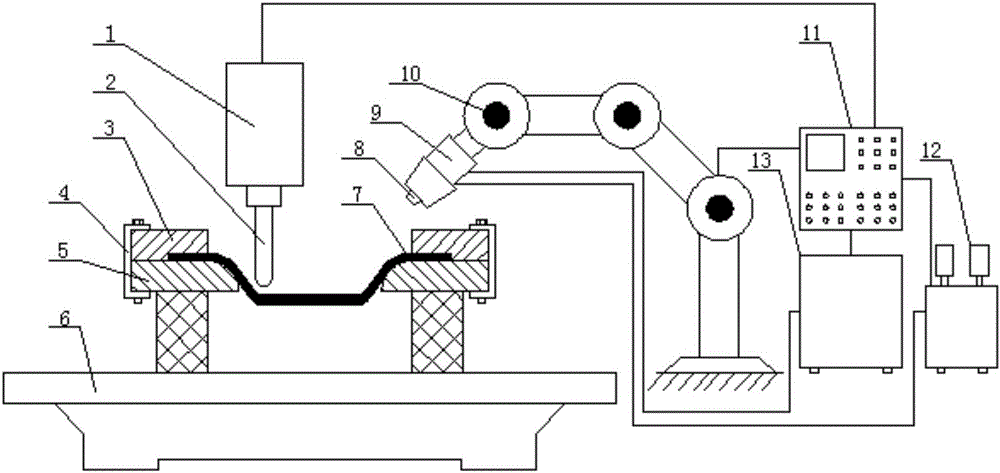

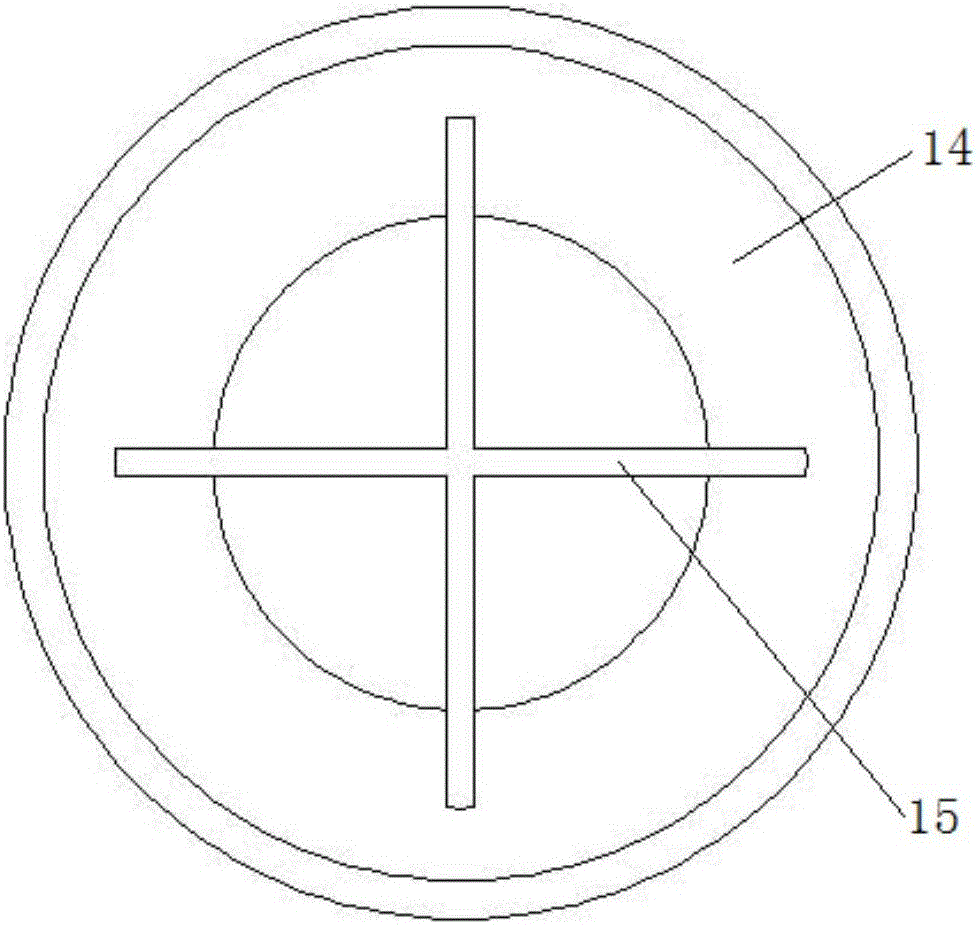

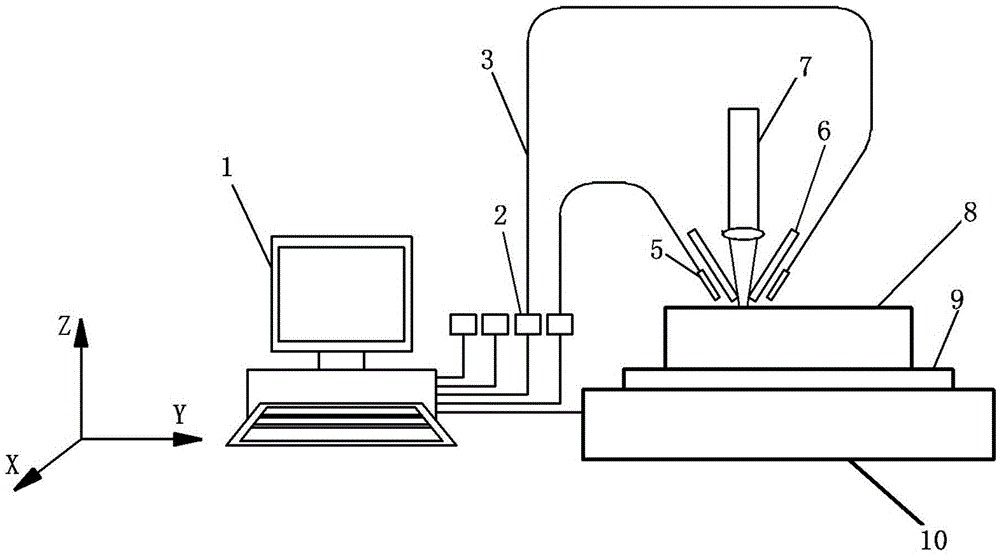

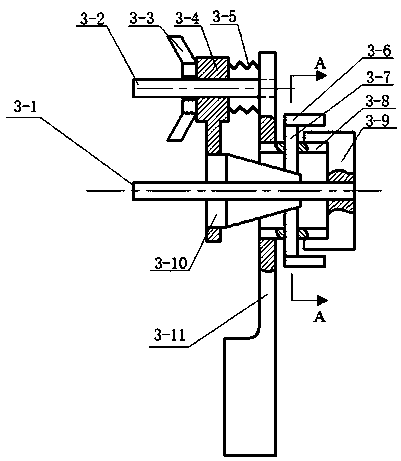

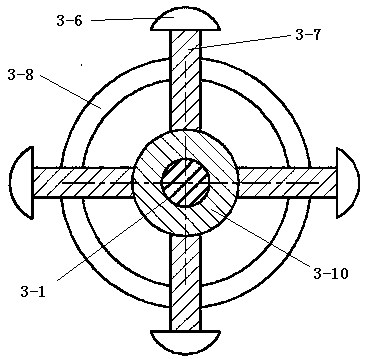

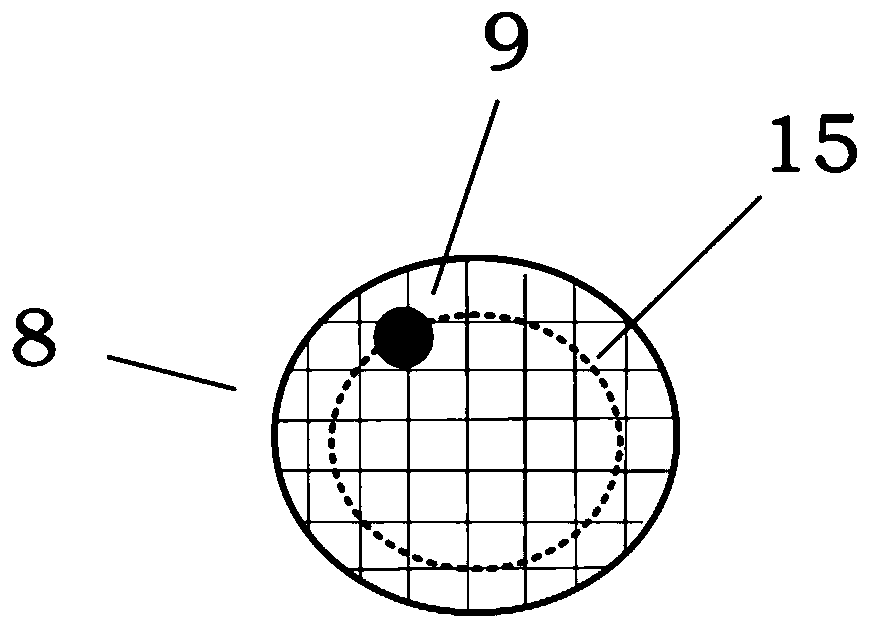

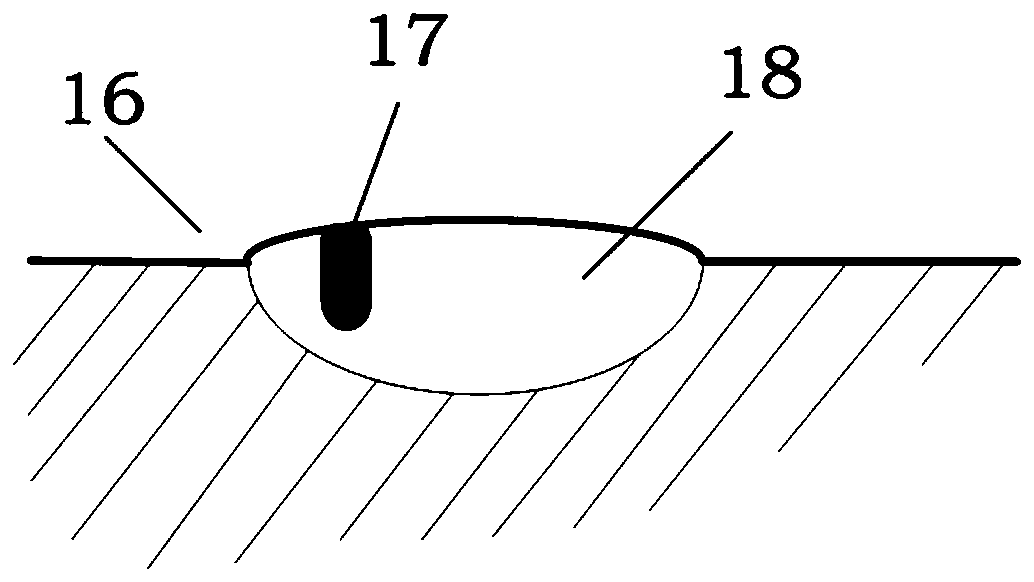

Online detecting and eliminating device and method for melt channel material defects in laser metal forming

InactiveCN105618740AEliminate internal material defectsEasy to useAdditive manufacturing apparatusThermometers using physical/chemical changesMaterial defectMetal forming

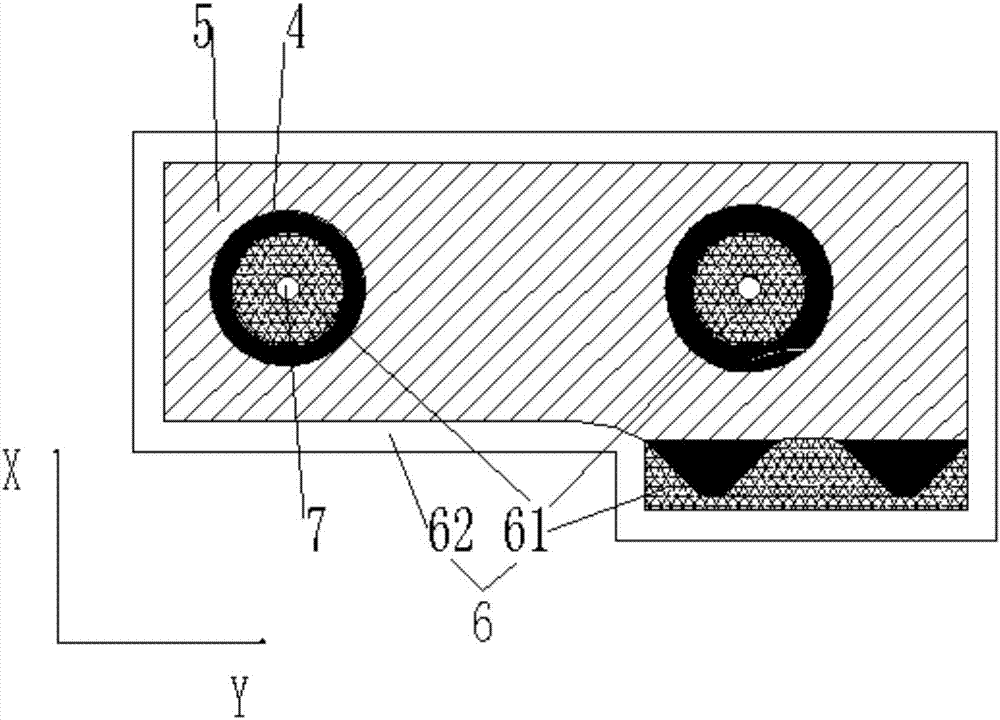

The invention discloses an online detecting and eliminating device and method for melt channel material defects in laser metal forming. The device and method are suitable for a laser metal deposition forming process. The device comprises four optical fiber type double-color temperature gauges, and four temperature measuring probes of the optical fiber type double-color temperature gauges are fixed to the left side, the right side, the front side and the back side of a coaxial powder feeding nozzle of a forming system correspondingly; detection aiming points of the four temperature measuring probes are aligned with the left side, the right side, the front side and the back side of a forming scanning laser spot on a forming plane correspondingly, the detection aiming points are away from the center of the laser spot by a certain micro-distance, and the four temperature measuring probes, the coaxial powder feeding nozzle and a laser beam move together; during forming, when the coaxial powder feeding nozzle and the laser beam conduct forming scanning in any one of the -X direction, the X direction, the -Y direction and the Y direction, the temperature measuring probe located at the side opposite to the scanning direction of the coaxial powder feeding nozzle is used for detecting the temperature of the position, away from the laser spot by a certain micro-distance, of a high-temperature melt channel, and when the temperature mutates abnormally, it is judged that the material defects exist in the position, the defect positions are determined, and laser targeted remelting is carried out on the defects.

Owner:XIAN UNIV OF TECH +2

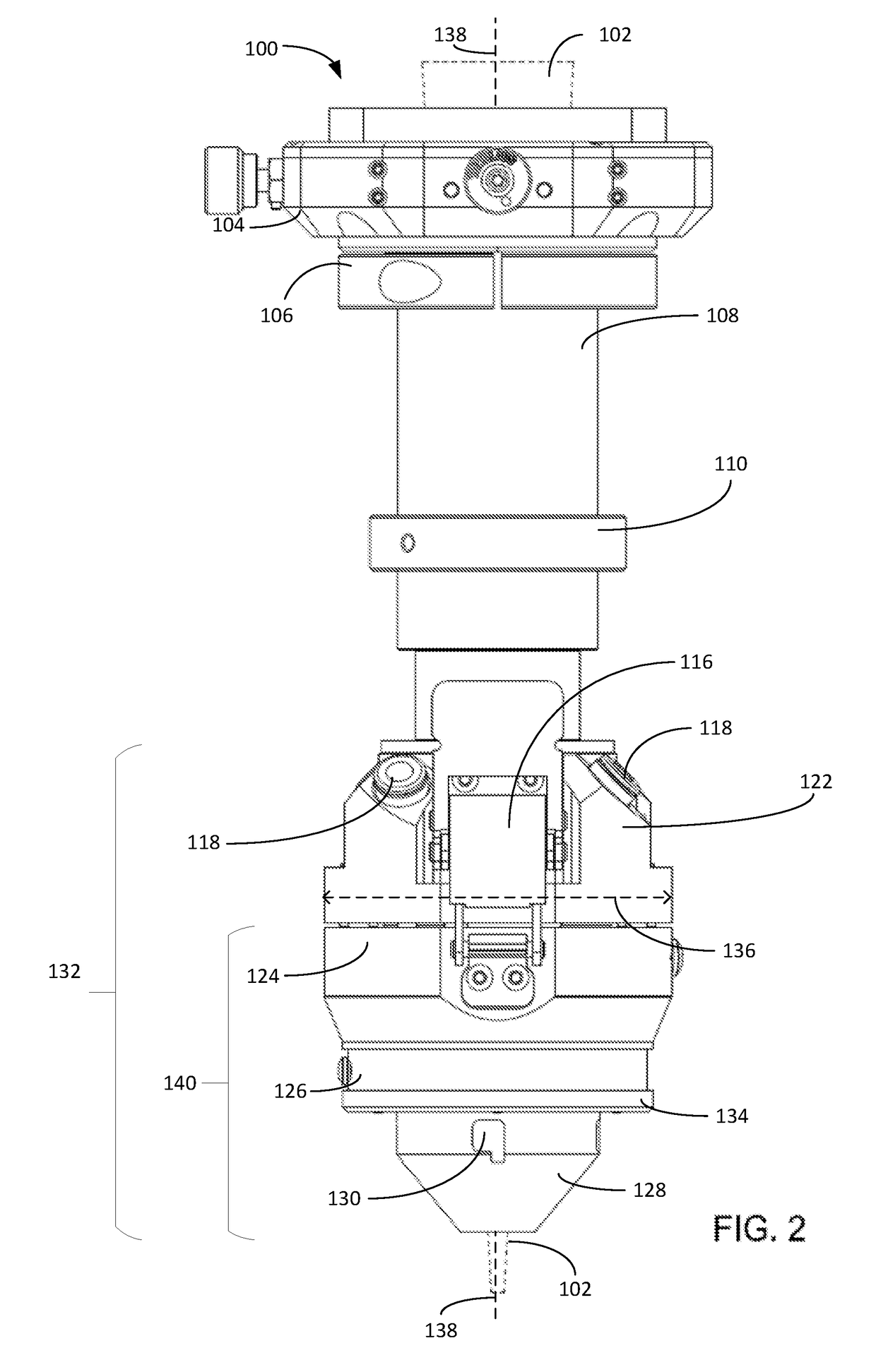

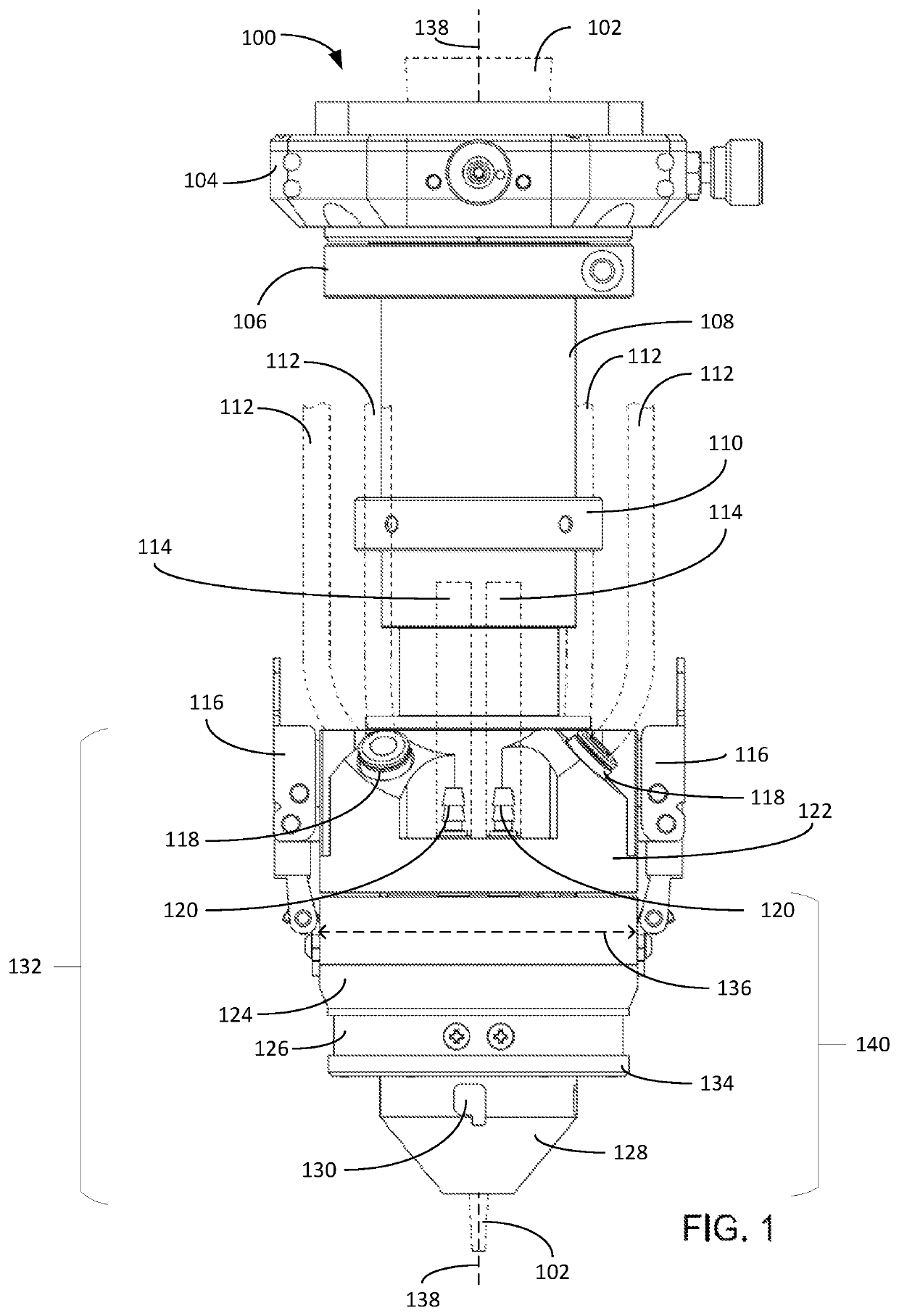

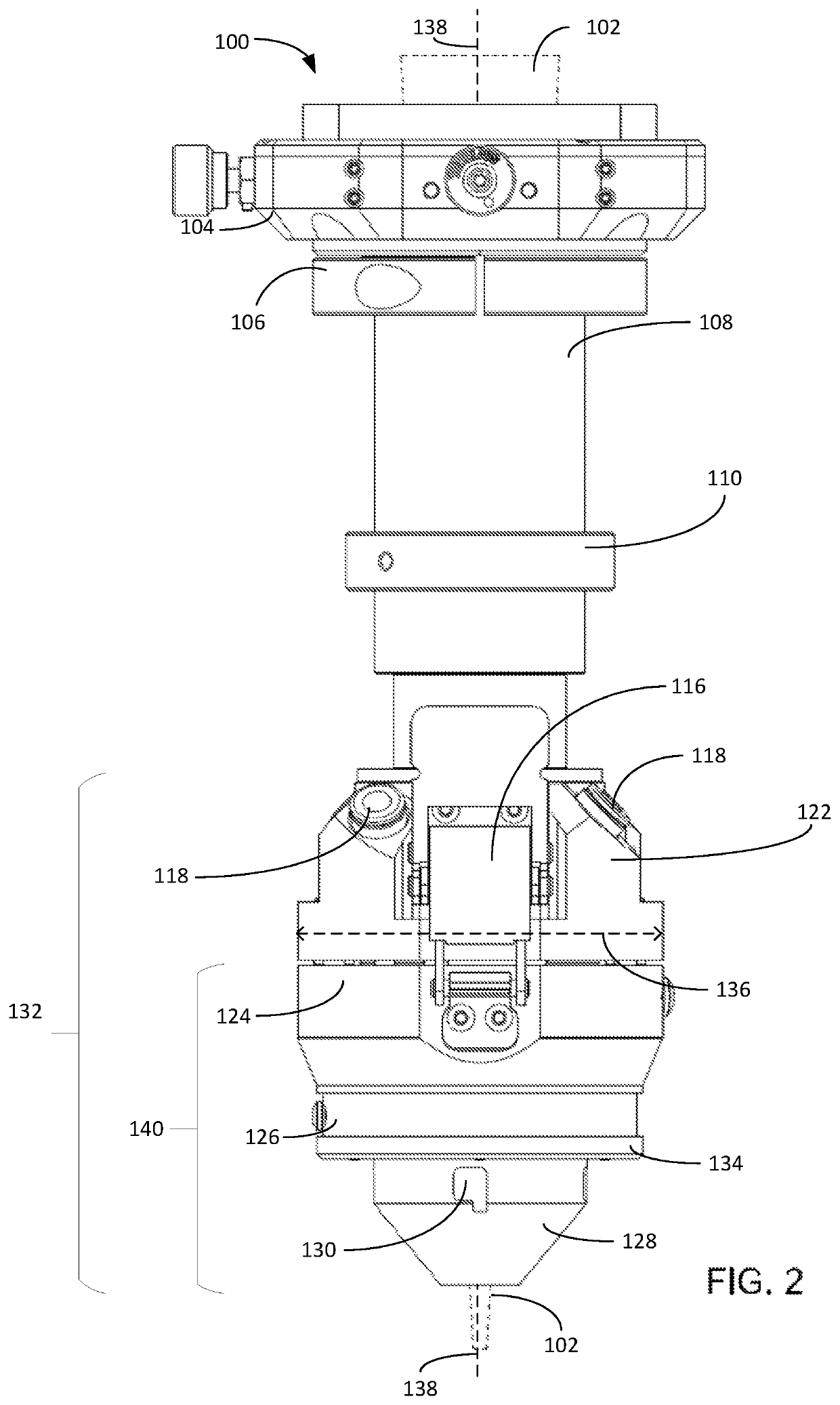

Laser metal deposition head

Aspects of the present disclosure relate to improved laser metal deposition heads. Various embodiments may include a main body, a nozzle seat, a powder flow guide, an inner nozzle, an outer nozzle, and a coolant sleeve. In some embodiments, powder inlets in the main body are angled relative to a primary axis of the laser metal deposition head. In some embodiments, the nozzle seat includes a plurality of powder distribution channels that are also angled relative to the primary axis of the laser metal deposition head.

Owner:FORMALLOY LLC

Laser based metal deposition (LBMD) of antimicrobials to implant surfaces

InactiveUS7951412B2Minimize adverse effectsHigh hardnessDental implantsFinger jointsWear resistantBone ingrowth

Owner:MEDICINELODGE

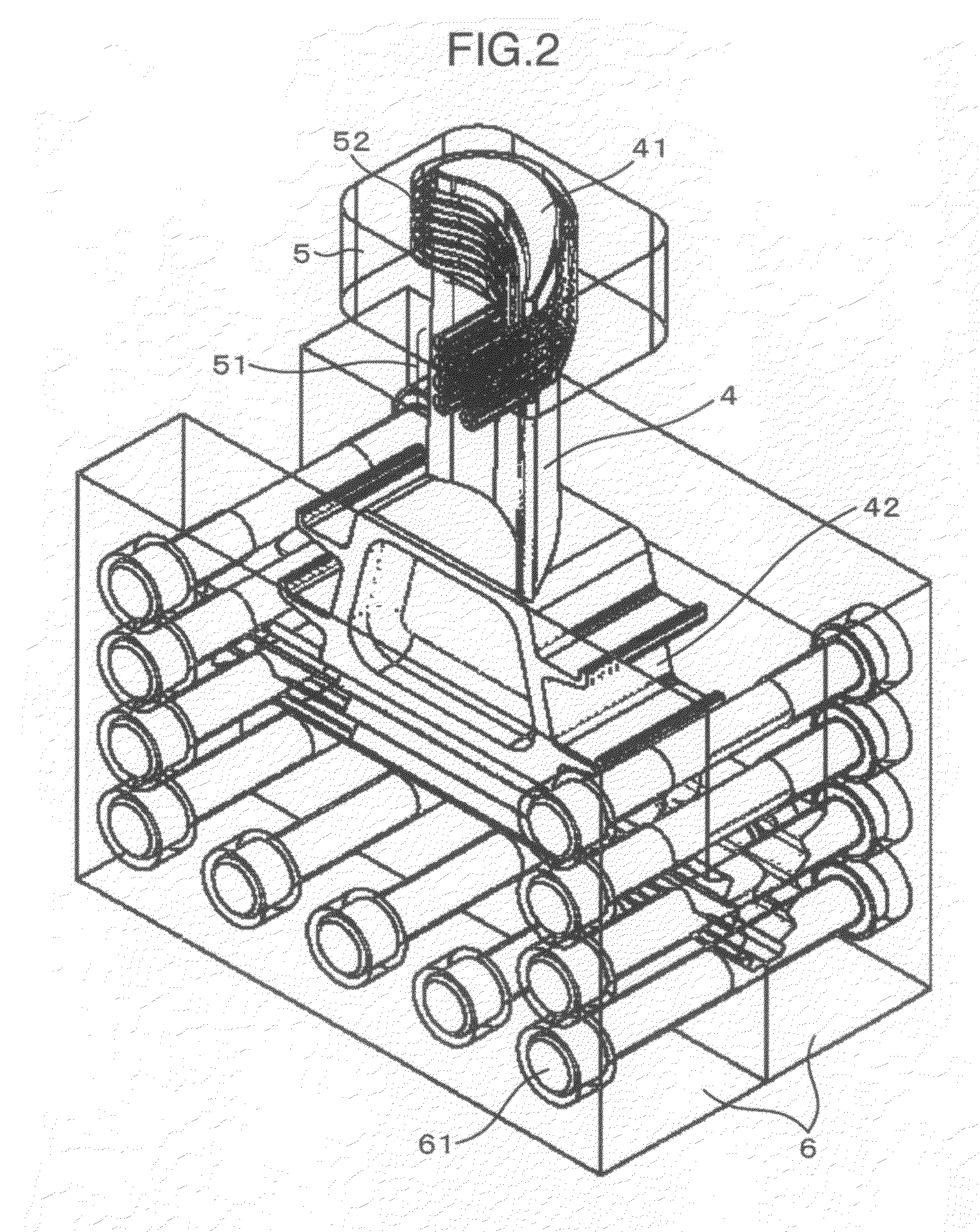

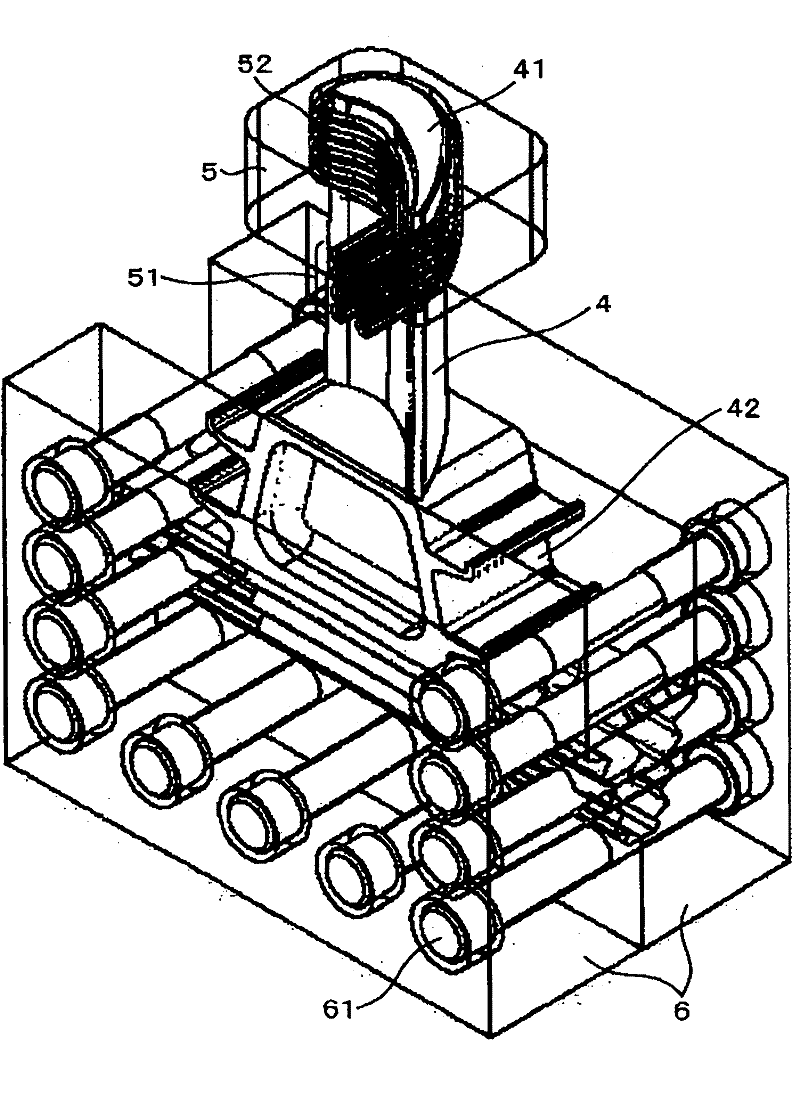

Metal deposition method and laser metal deposition apparatus

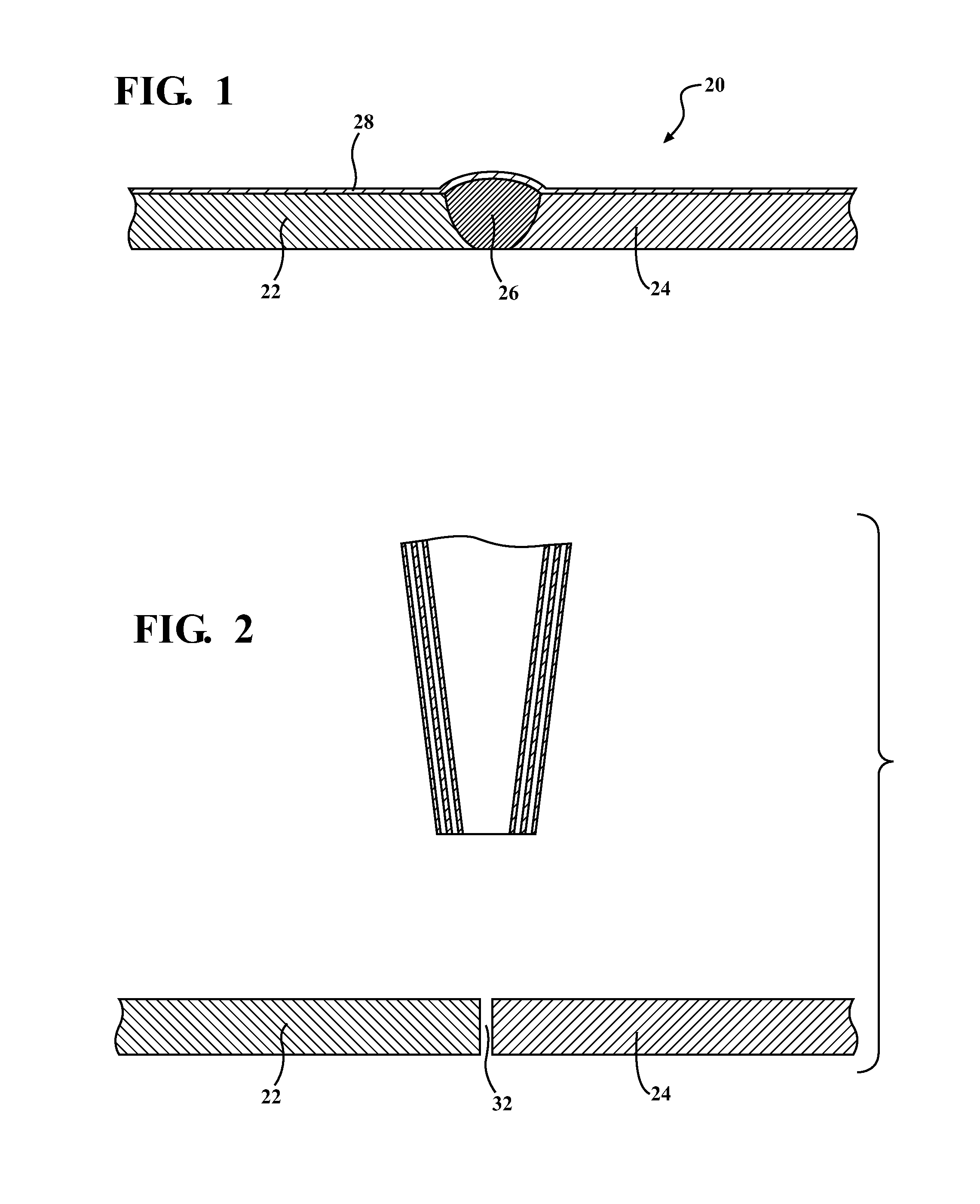

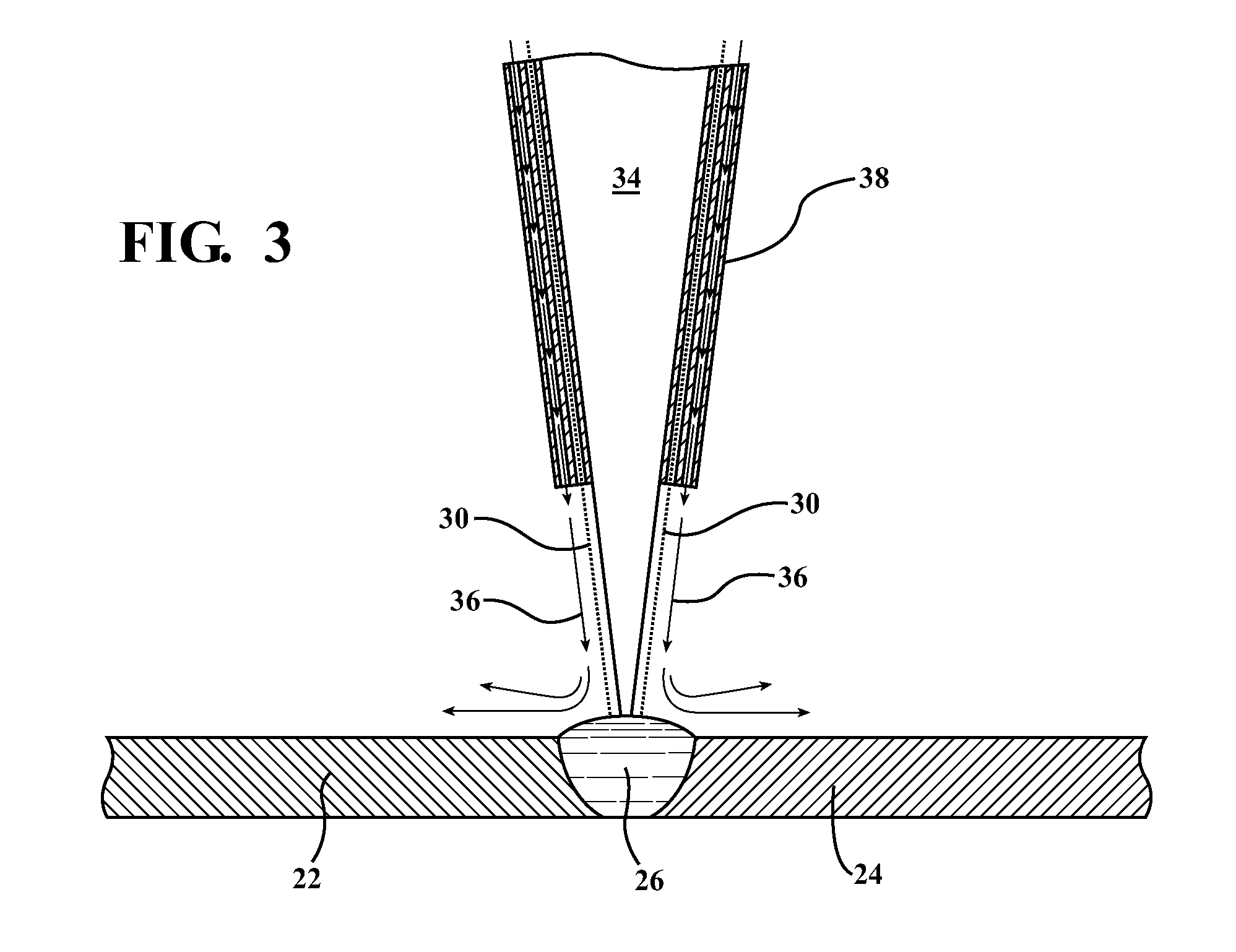

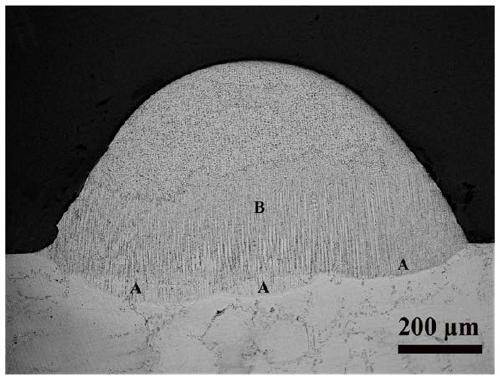

InactiveUS20110248001A1Control coarseningLimit solidification rateTurbinesPolycrystalline material growthSingle crystalDirectional solidification

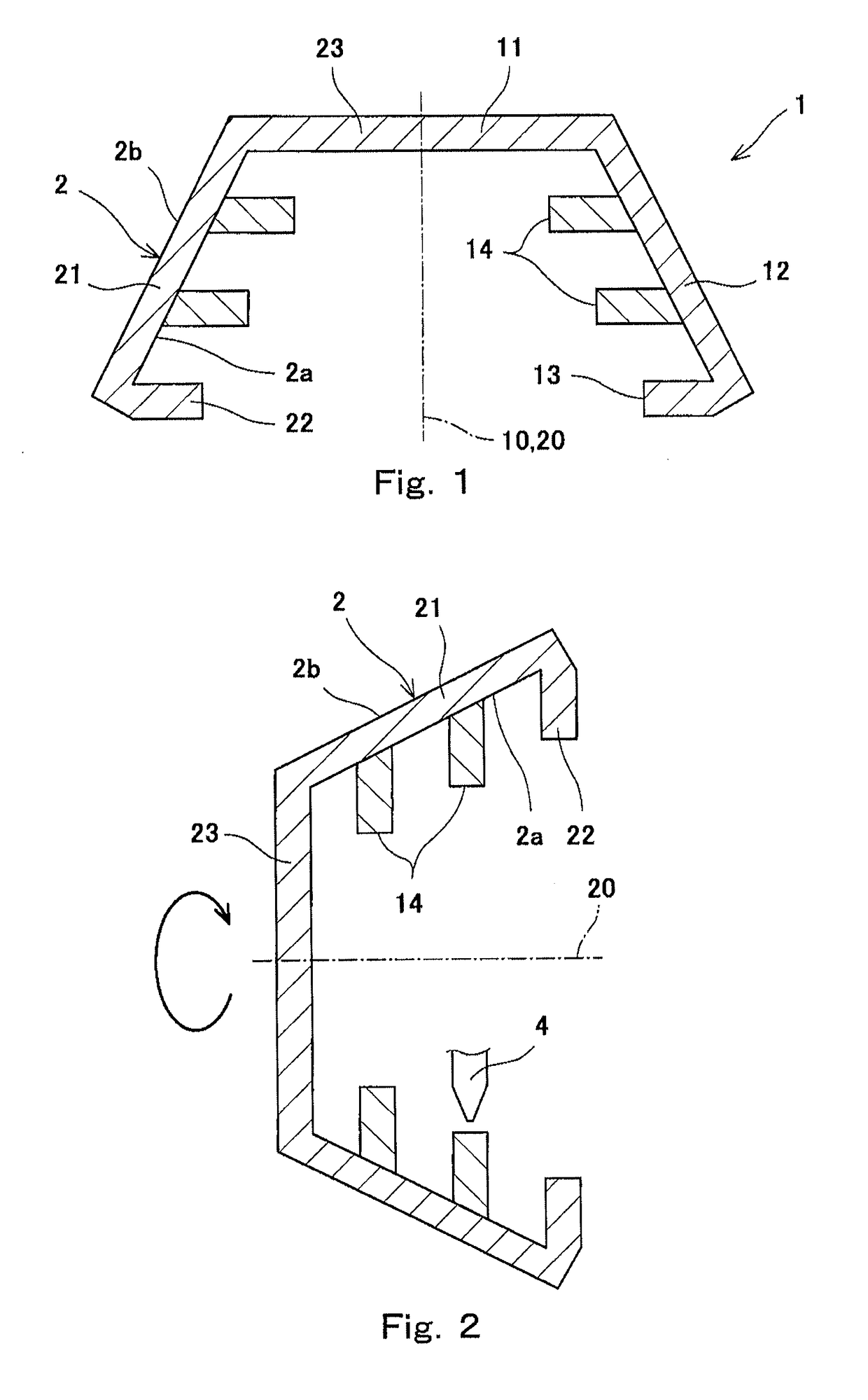

In a deposition method of forming a buildup on a single crystal or directionally solidified crystal parent material, metal deposition is performed from an extension in a preferential growth orientation of parent material crystals while forcedly cooling a portion of the parent material somewhat below a processed surface and beforehand giving a temperature gradient to the parent material so that a maximum temperature gradient is oriented along the preferential growth orientation of parent material crystals.

Owner:HITACHI LTD

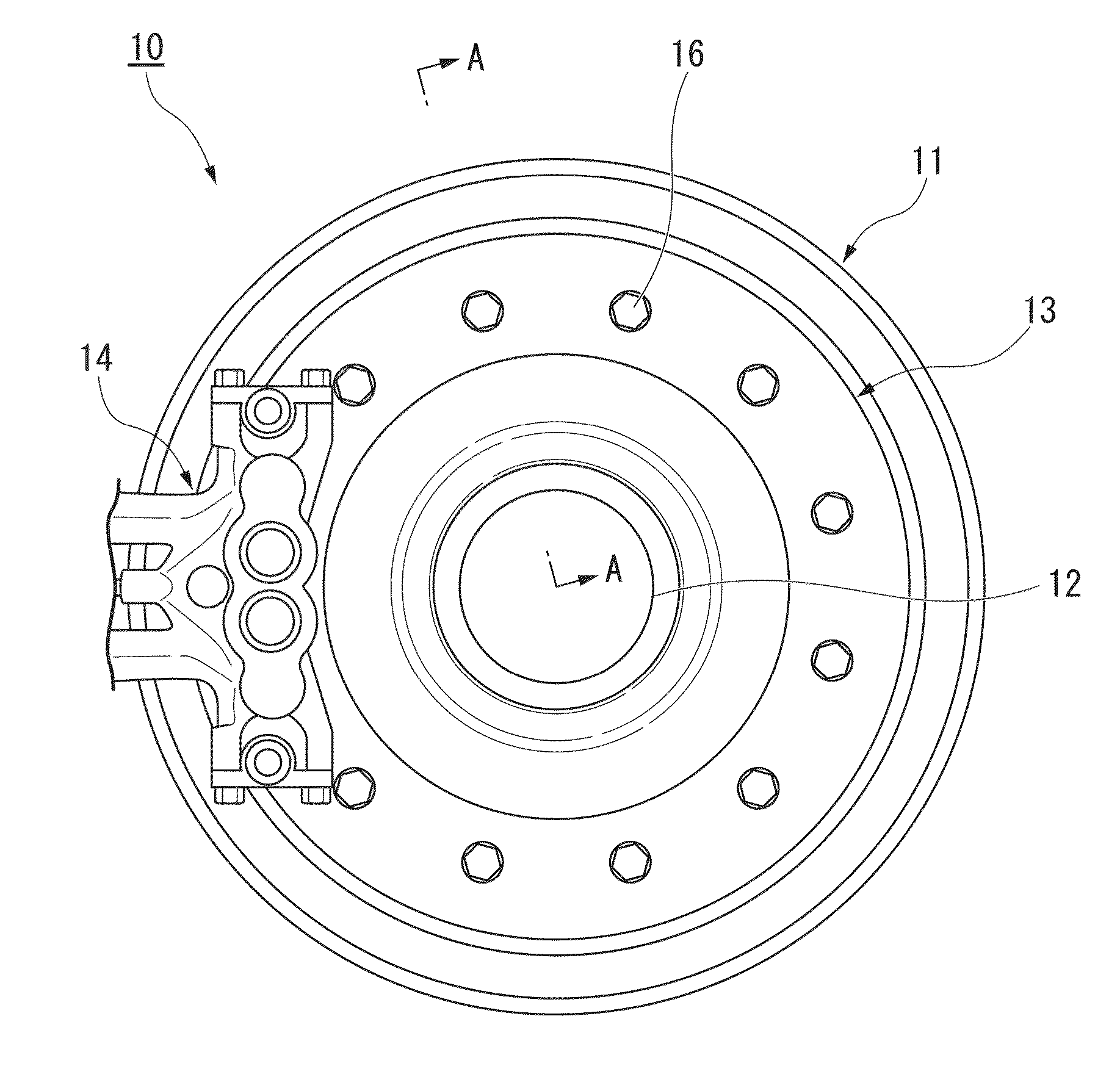

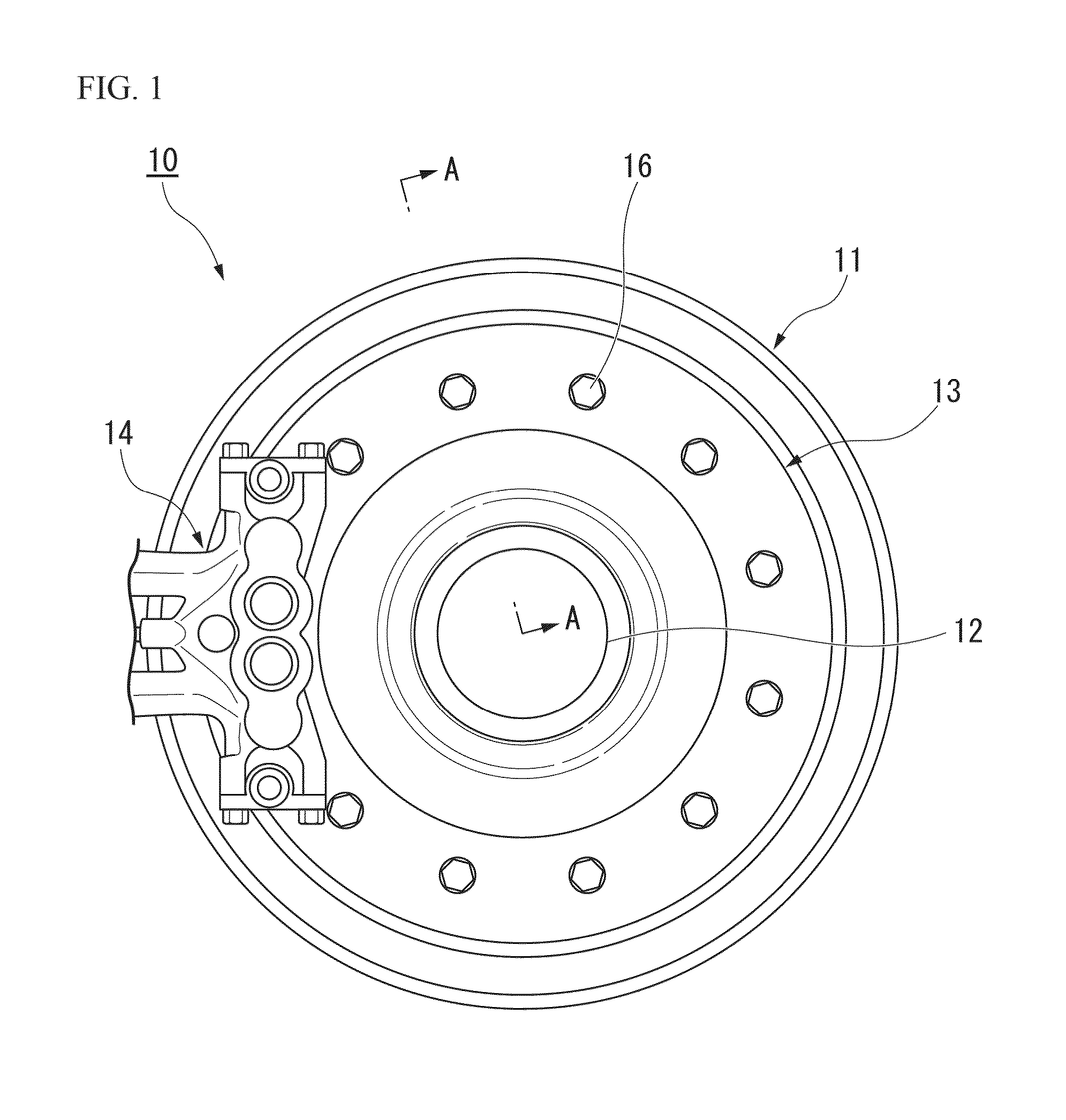

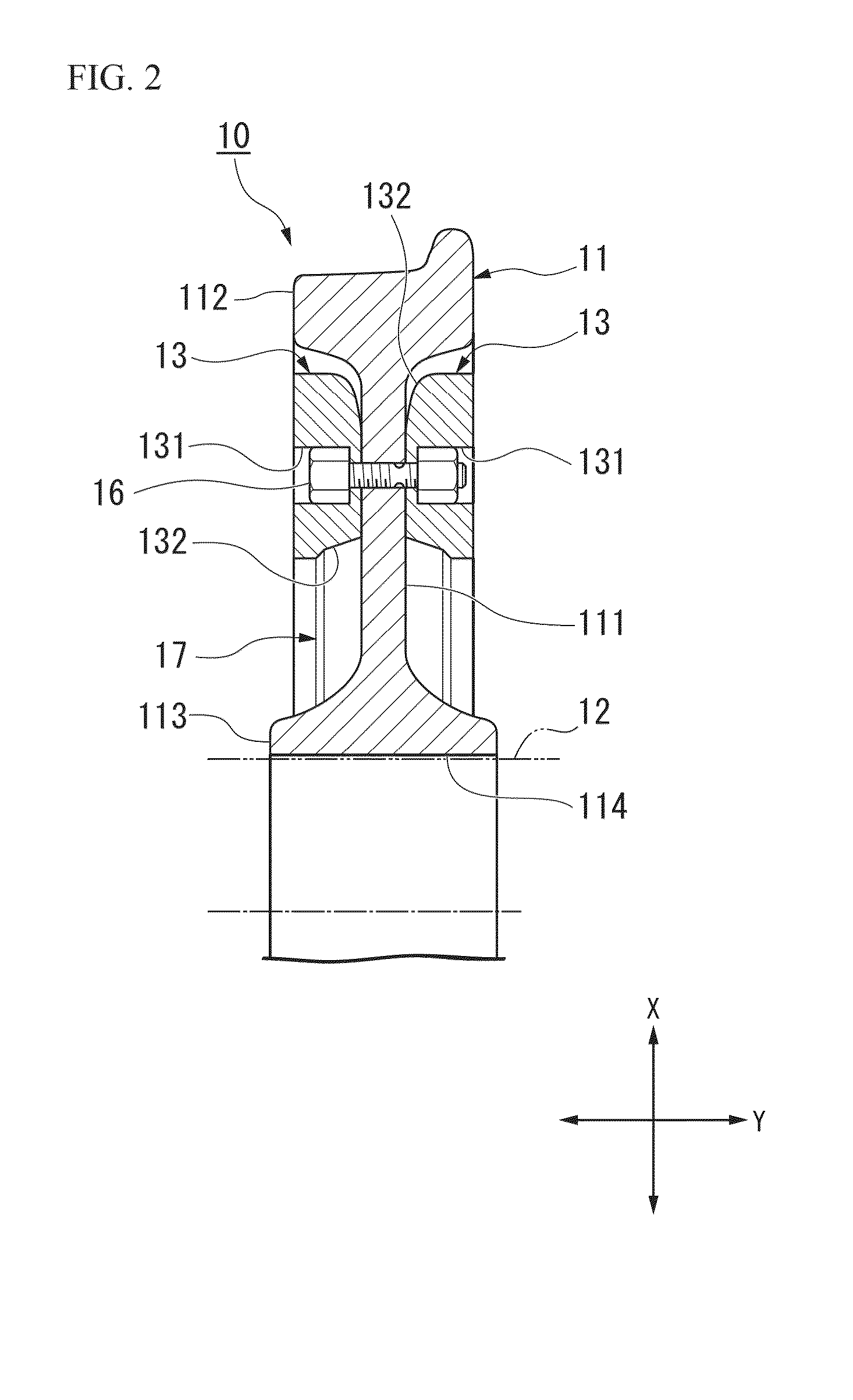

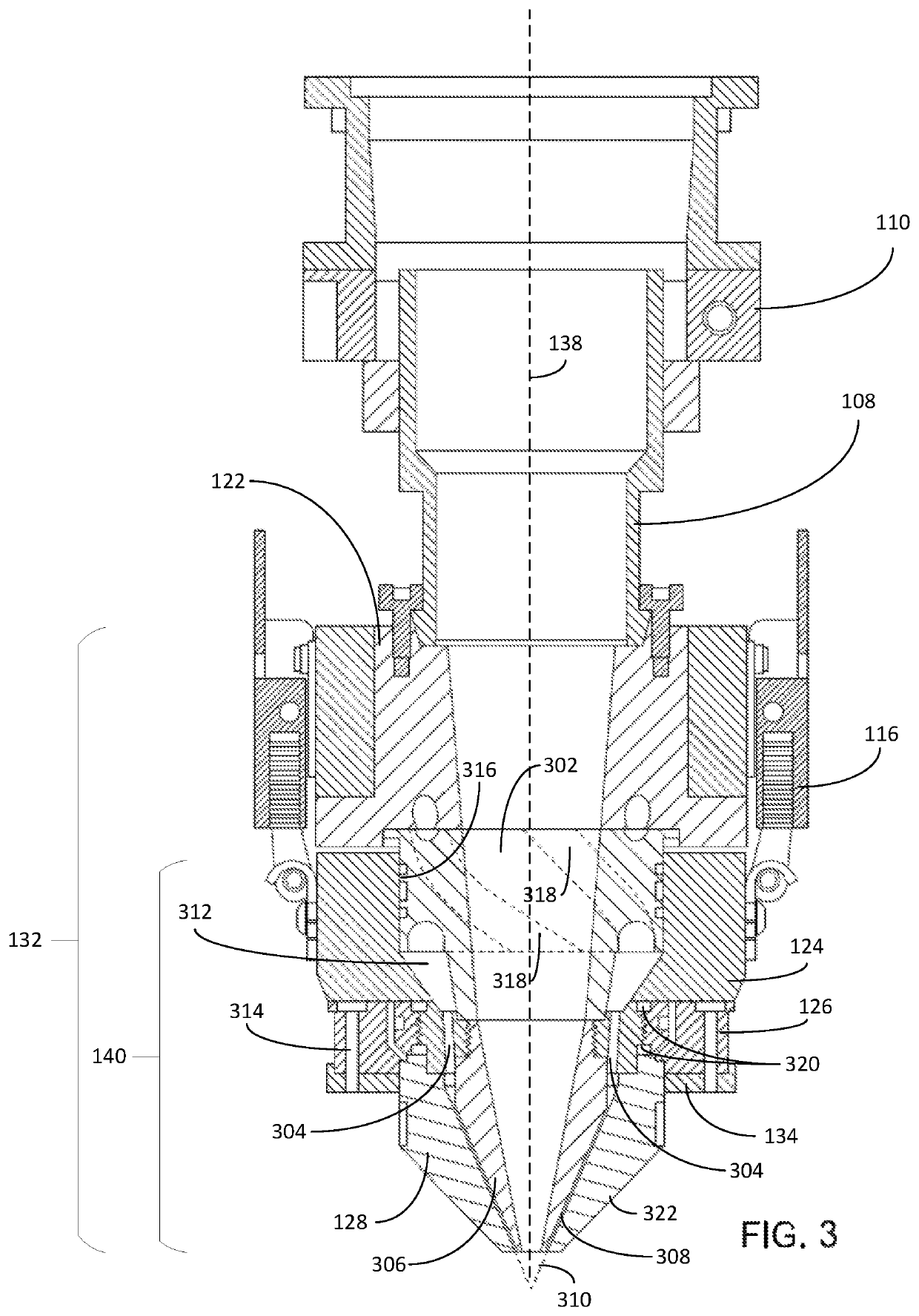

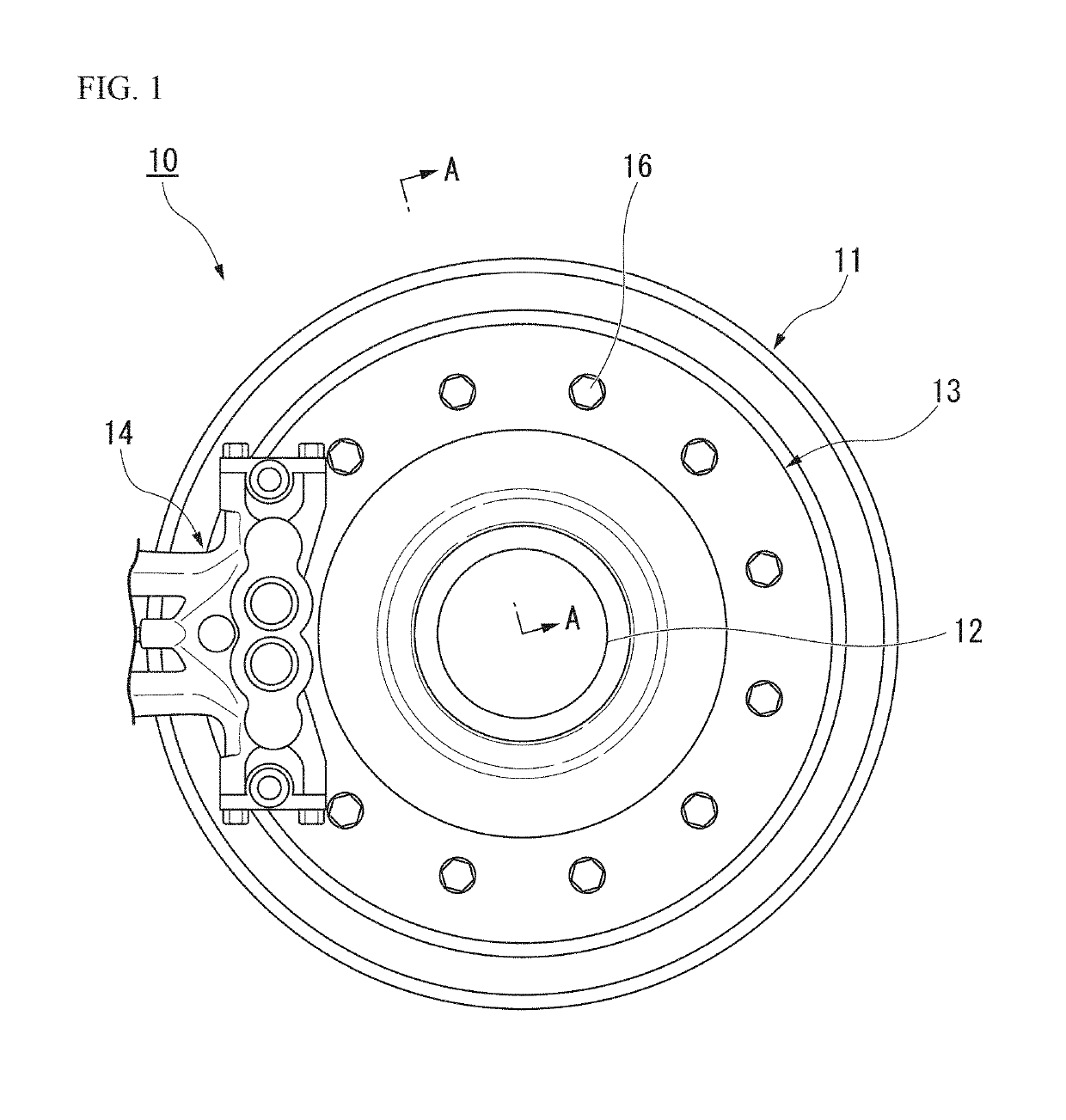

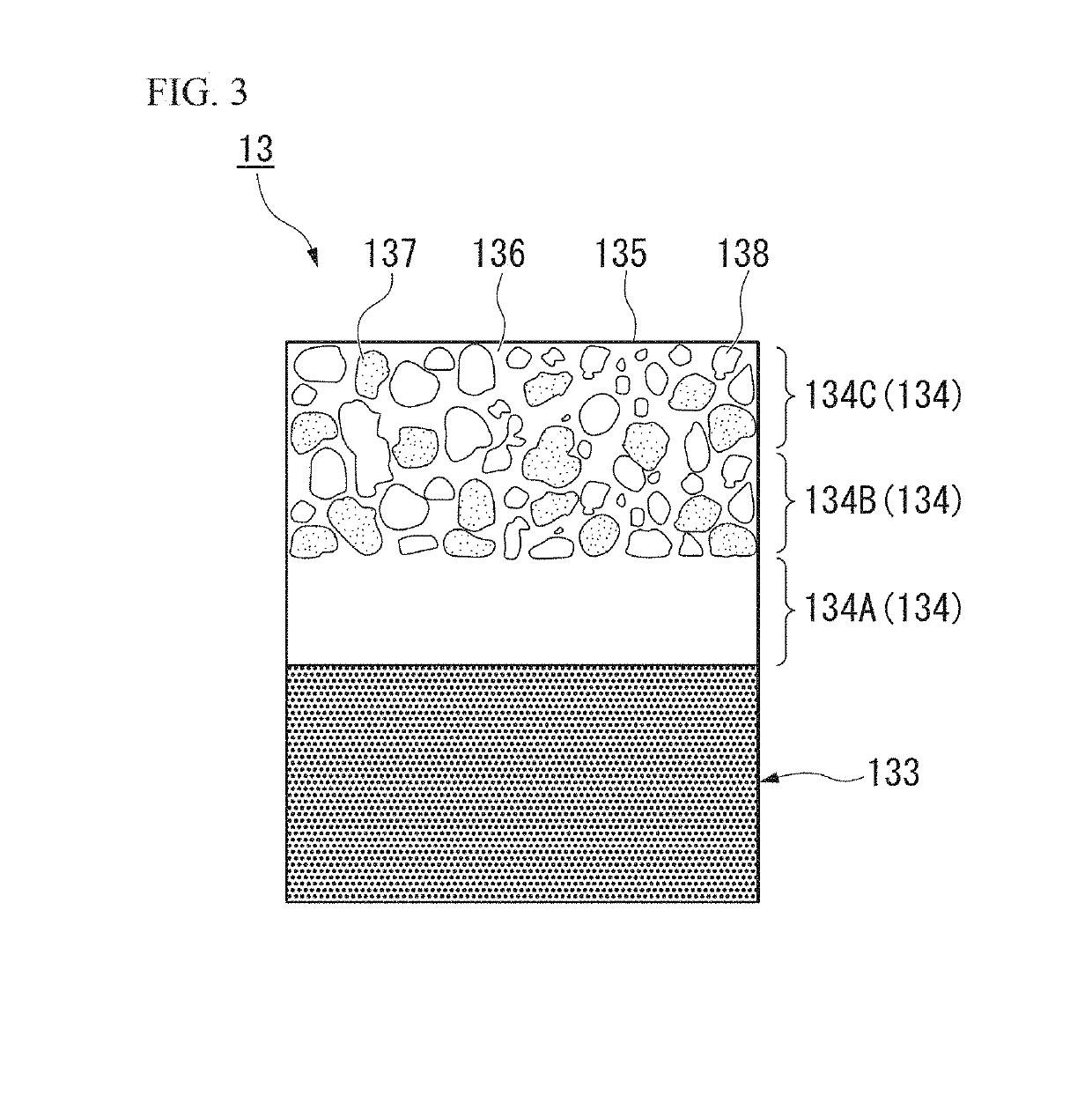

Brake disc and manufacturing method thereof

ActiveUS20160223041A1Reduce thicknessSuppression of distortionAdditive manufacturing apparatusBraking discsMechanical engineeringBrake pad

A brake disc of the present invention is a brake disc that stops the rotation of an axle when a brake pad is pressed on a surface of the brake disc, including a disc main body that is attached to a rotary body integrally rotating with the axle; and a plurality of build-up layers laminated on a surface of the disc main body, in which the build-up layers are laminated on the surface of the disc main body by means of laser metal deposition welding.

Owner:RAILWAY TECH RES INST +1

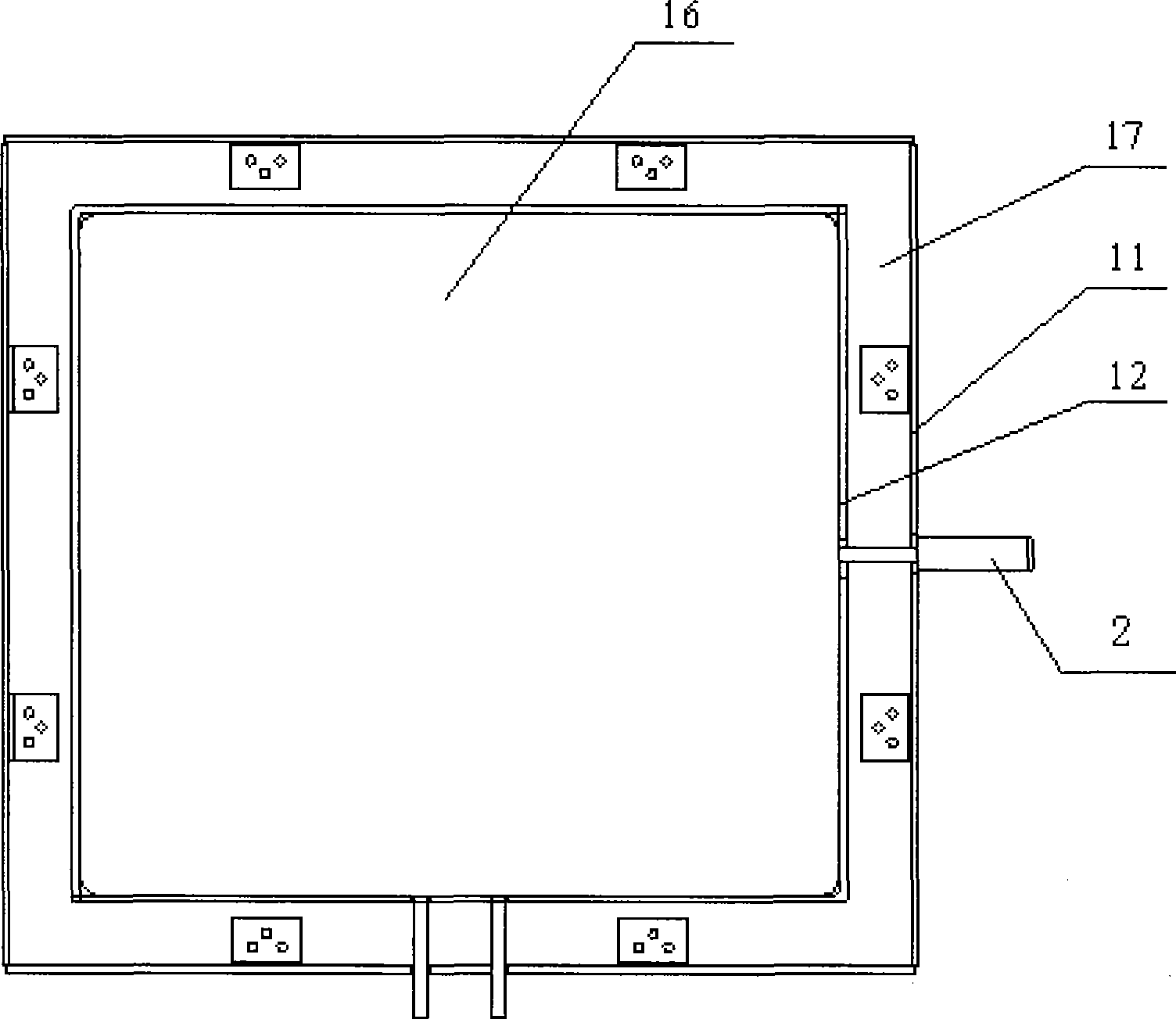

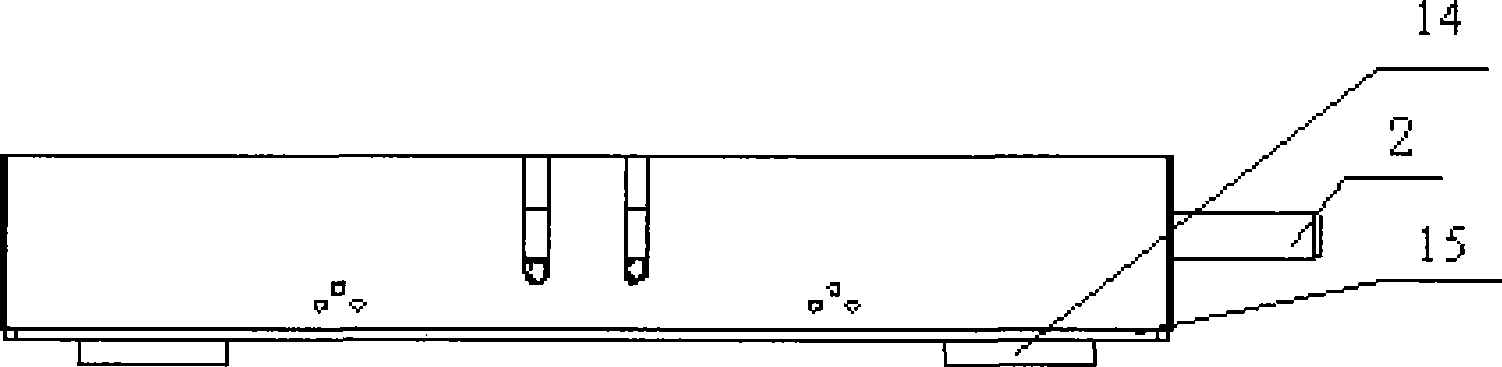

Basal plate preheating system formed by laser metal deposition

InactiveCN101392371AGuarantee quality requirementsGuaranteed dimensional accuracy requirementsMetallic material coating processesLaser beam welding apparatusTemperature controlEffective solution

The invention relates to a basic plate preheating system of laser metal deposition shaping. The basic plate preheating system comprises a basic plate pre-heater and a temperature control device thereof, wherein, the basic plate pre-heater has a box structure and is provided with a bottom plate, internal walls and external walls arranged around the bottom plate; heat insulating materials are arranged between the internal walls and the external walls; an electric heating pipe is installed on the bottom plate by the heat insulating materials and copper plates are arranged in the box body and over the electric heating pipe; and a wiring terminal of the electric heating pipe is connected with the temperature control device. The basic plate preheating system provides a stable temperature field for the laser metal deposition shaping technique, effectively reduces the temperature gradient of a sample and the basic plate during the shaping, and has high automation, good uniformity in preheating of the basic plate and high control precision, thus providing an effective solution to cracks or even breaks existing in the laser metal deposition shaping technique.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

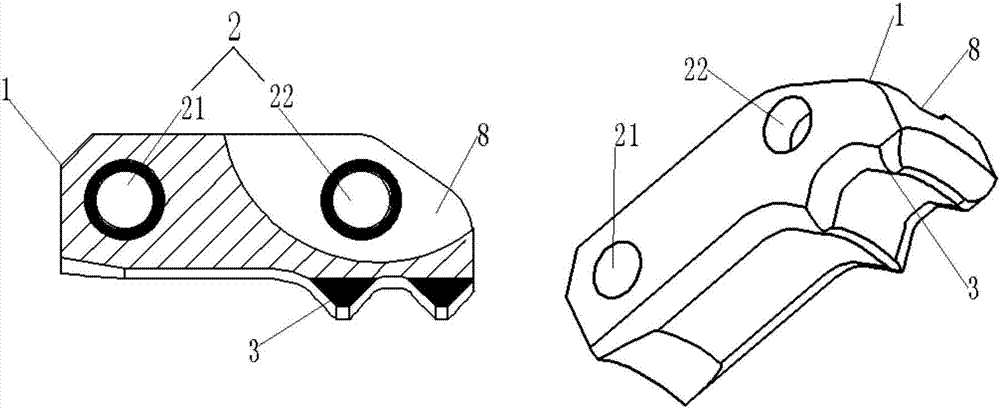

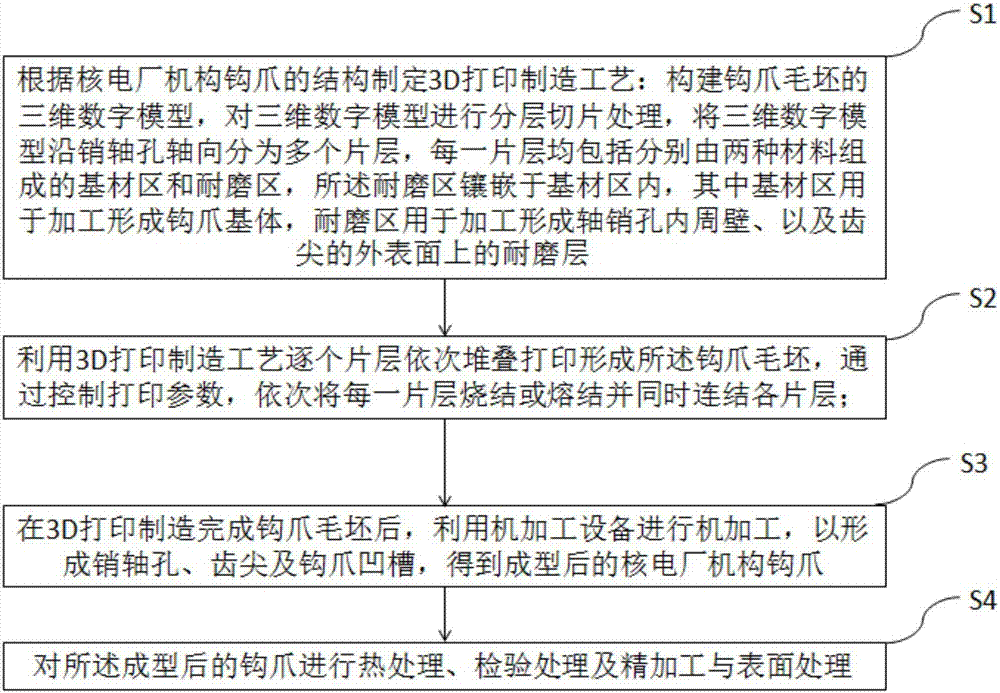

Nuclear power plant control rod driving mechanism hook jaw and preparation method thereof

ActiveCN107351104AImprove reliabilityImprove mechanical propertiesAdditive manufacturing apparatusGripping headsEngineeringWear resistance

The invention discloses a nuclear power plant control rod driving mechanism hook jaw and a preparation method thereof. The hook jaw comprises a hook jaw body formed by printing two materials by multiple layers in a sequential stacking manner, and wear resisting layers; and the wear resisting layers are formed on the inner peripheral wall of a shaft pin hole and the outer surface of a tooth tip in an embedding manner. The preparation method comprises the following steps: (S1) a 3D printing manufacturing process is formulated according to the structure of the hook jaw; (S2) the 3D printing manufacturing process is used for sequentially stacking multiple layers to print a hook jaw blank; and (S3) after the hook jaw blank is manufactured by 3D printing, machining equipment is used for machining to form the pin shaft hole, the tooth tip and a hook jaw groove to obtain the molded hook jaw. The material organization of the hook jaw is improved by dint of laser metal deposition, so that each part of the hook jaw manufactured by dissimilar materials is more compact and more uniform, the mechanical performance is greatly improved, the surface wear resistance and the impact resistance are improved, and meanwhile, the yield of the hook jaw and the long-time service reliability are improved.

Owner:CHINA NUCLEAR POWER DESIGN COMPANY +2

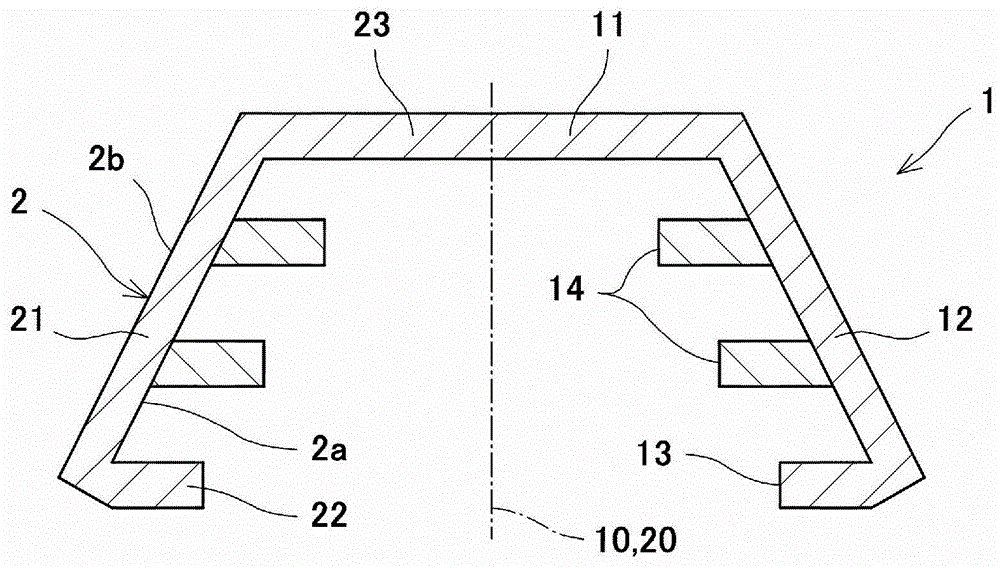

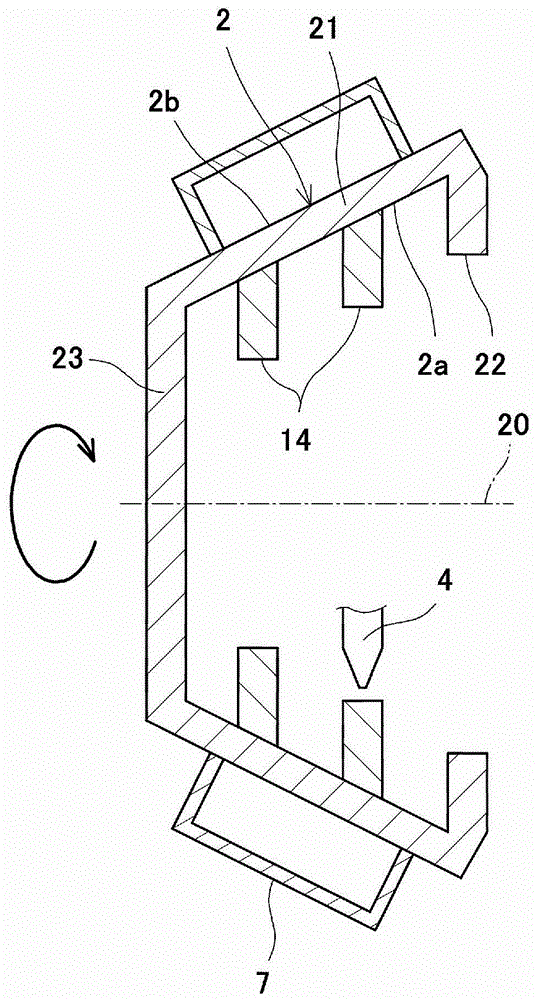

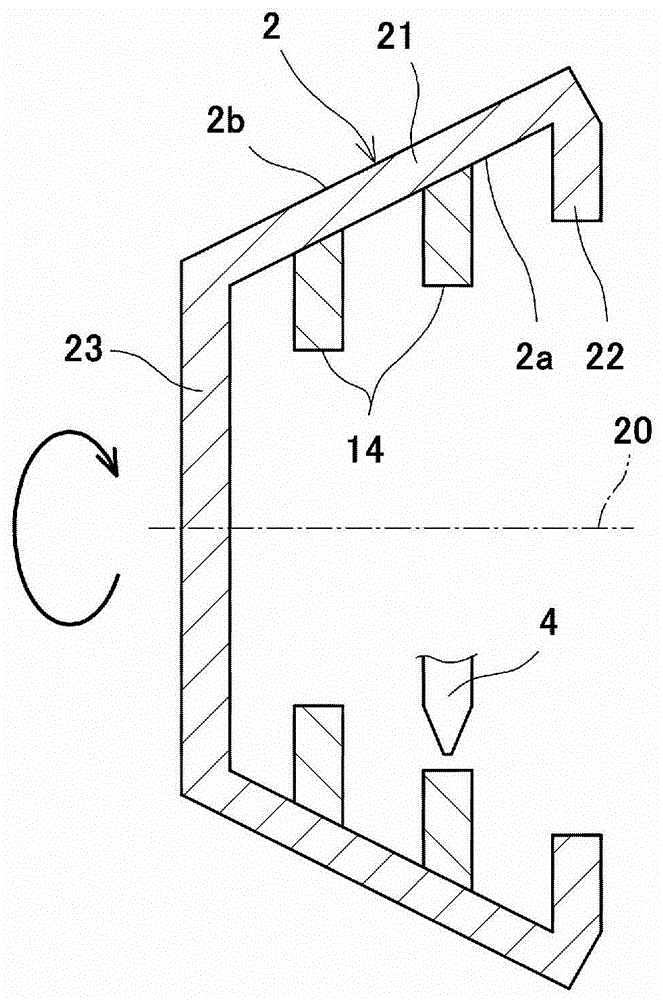

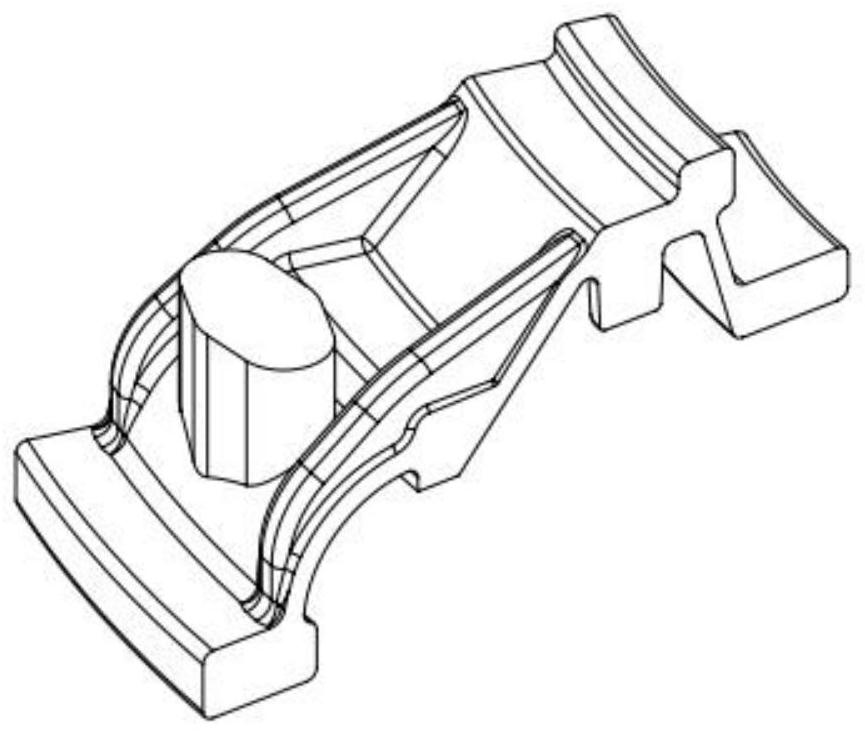

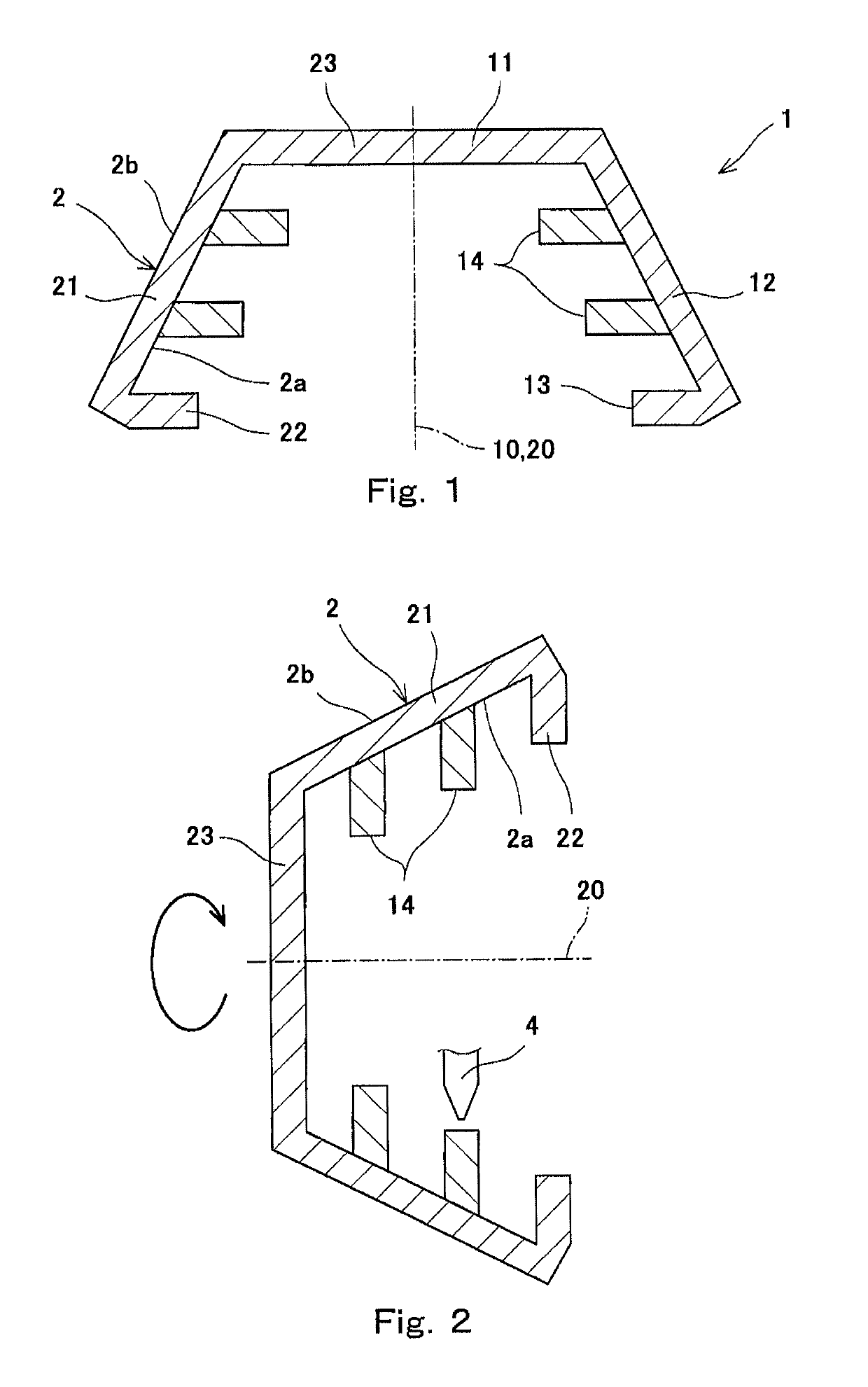

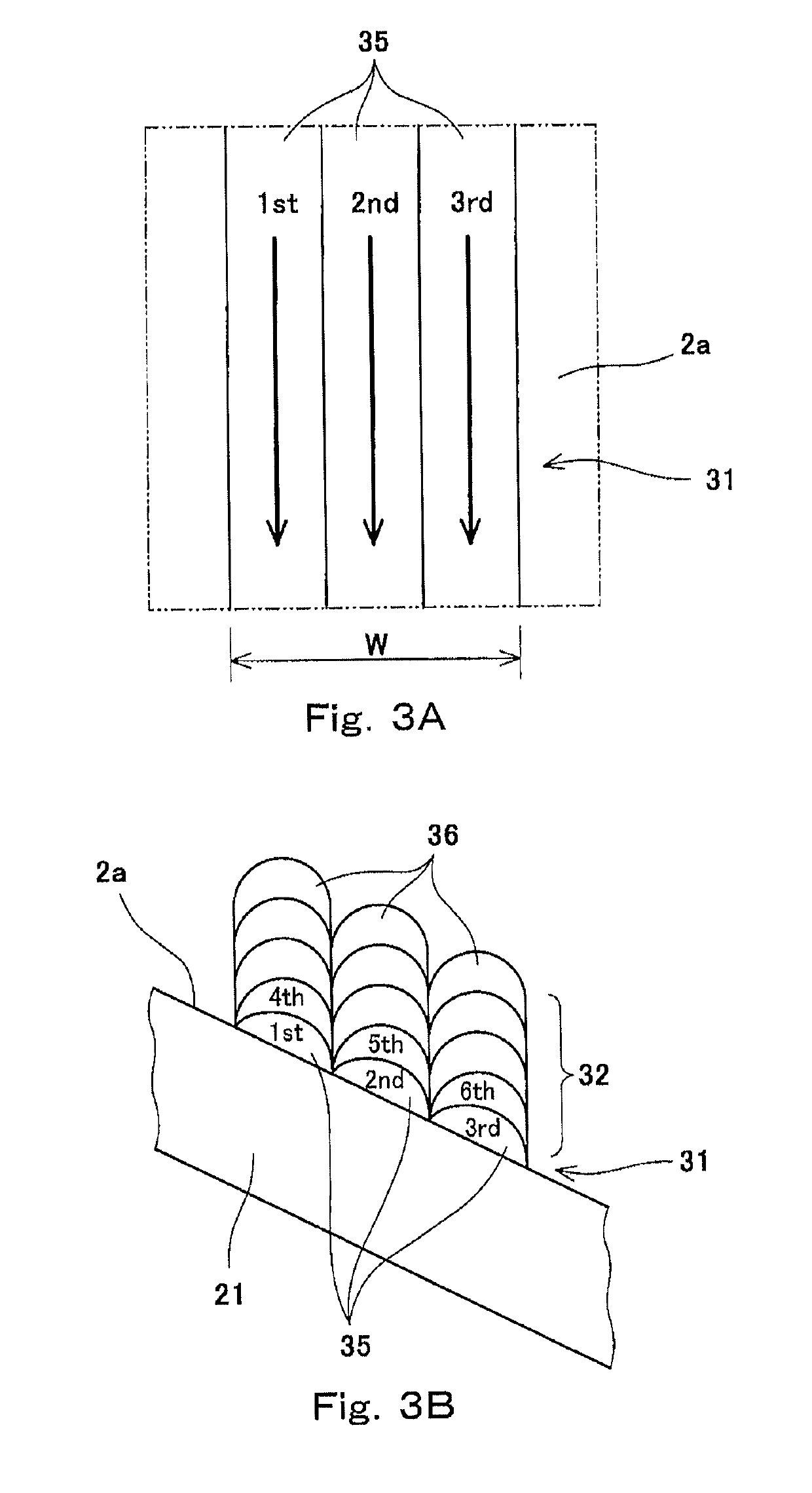

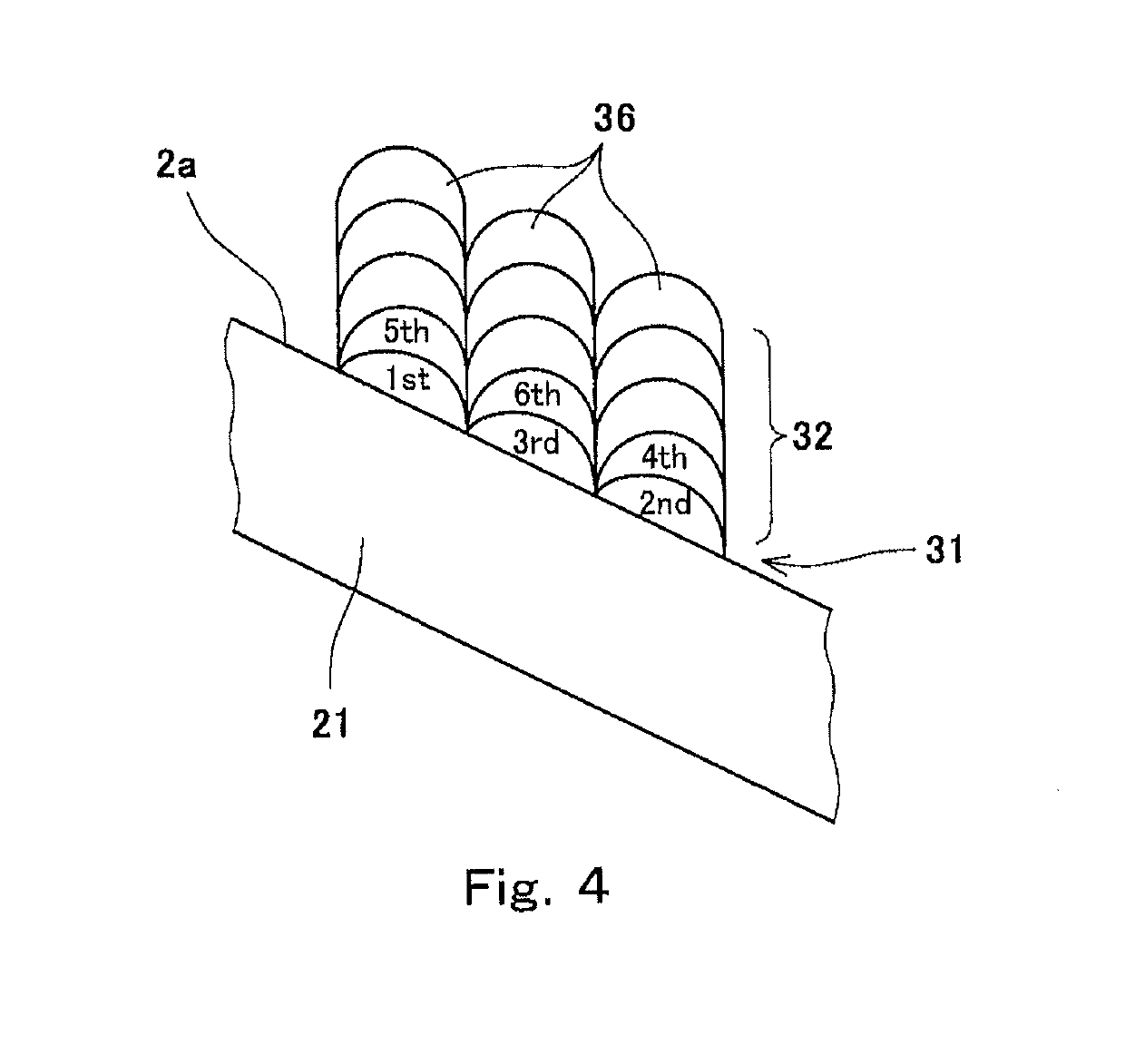

Methods of manufacturing axisymmetric body and axisymmetric product

ActiveUS20170120385A1Wider widthAdditive manufacturing apparatusIncreasing energy efficiencyHeat-affected zoneEngineering

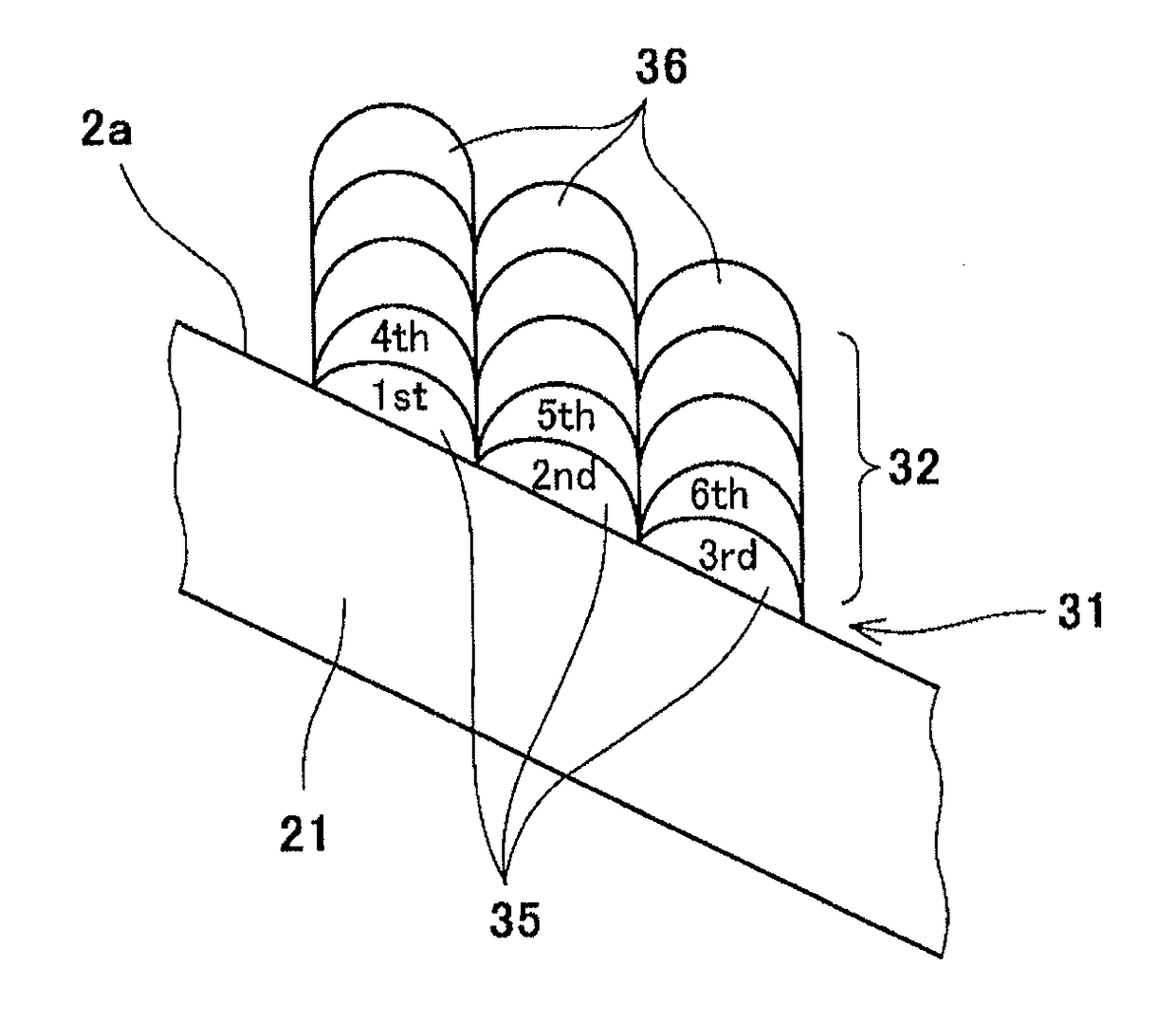

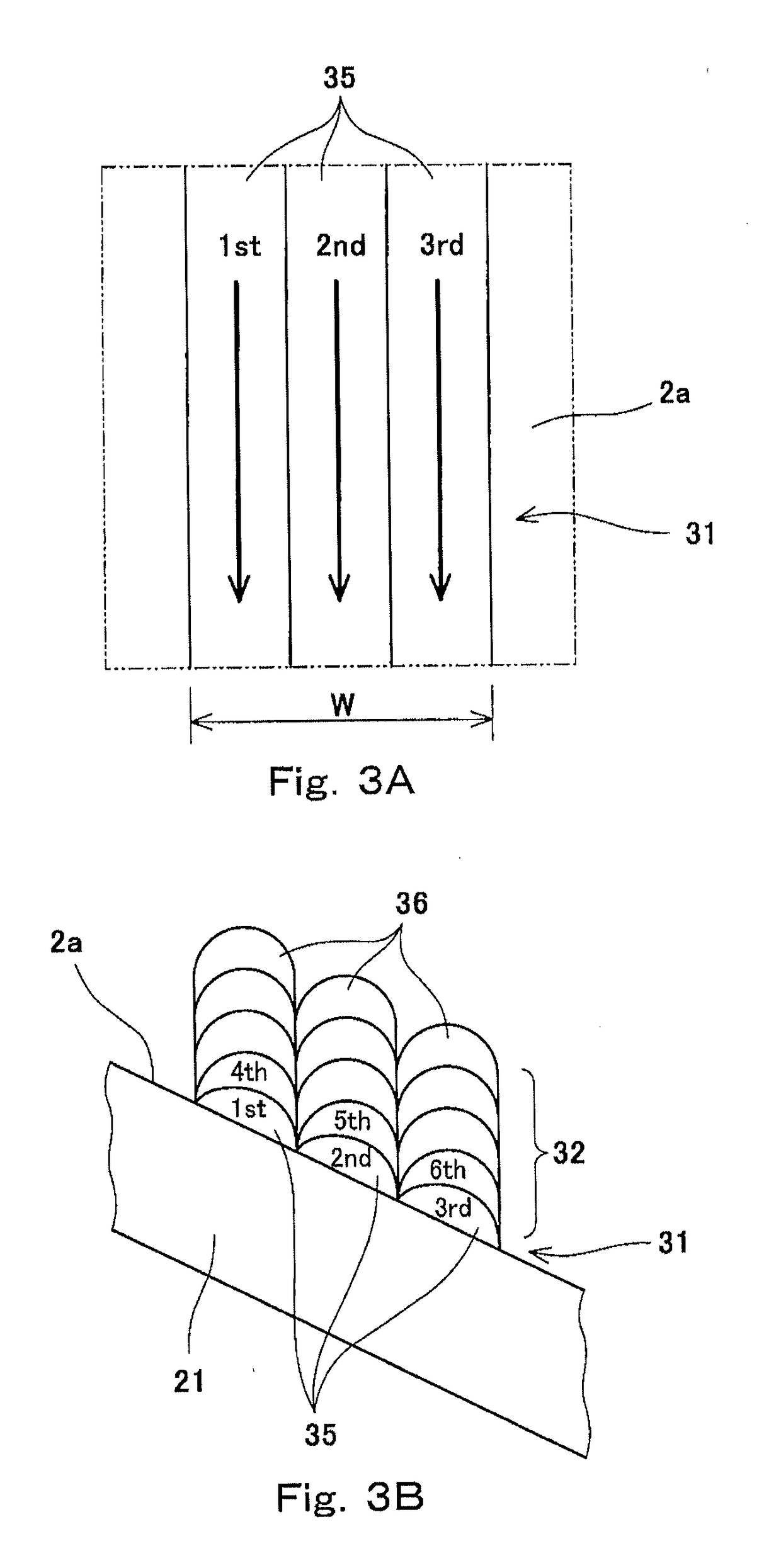

First, an annular first layer including a plurality of beads and having a width that is not less than twice a width of the bead is formed by laser metal deposition on a peripheral surface of a base metal, the peripheral surface facing outward or inward in a radial direction. Next, a plurality of annular height raising layers each including a plurality of beads are stacked on the first layer by the laser metal deposition. According to this configuration, an axisymmetric body including a flange portion having a relatively wide width can be manufactured while making a heat affected zone in the base metal extremely small.

Owner:KAWASAKI HEAVY IND LTD

Axially symmetric body, and axially symmetric body manufacturing method

InactiveCN106660175AAdditive manufacturing apparatusIncreasing energy efficiencyHeat-affected zoneOptoelectronics

An annular initial layer (31) comprising multiple beads (35, 36) is formed by laser metal deposition on the radially inwards- or outwards-facing peripheral surface of a base material (2), the width of the initial layer (31) being at least twice the width of the beads (35, 36), and multiple annular raised layers (32), each comprising multiple beads, are laminated on the initial layer by laser metal deposition. By this means, an axially symmetric body (5) having a relatively wide flange can be manufactured while the portion of the base material (2) that is affected by heat is kept extremely small.

Owner:KAWASAKI JUKOGYO KK

Laser metal deposition welding of automotive parts

ActiveUS20150251274A1Smoother and harderEfficient and cost-effectivePhosphatisationElectrophoretic coatingsMotor vehicle partWeld seam

A part, such as an automotive part, is provided. The part includes at least two work pieces of steel which are joined together at a weld seam which includes at least one of nickel and iron and is substantially entirely free of silicate islands. The part also includes a painted, phosphated or electrocoated coating which is bonded with at least a portion of the substantially entirely silicate island free weld seam.

Owner:MAGNA INTERNATIONAL INC

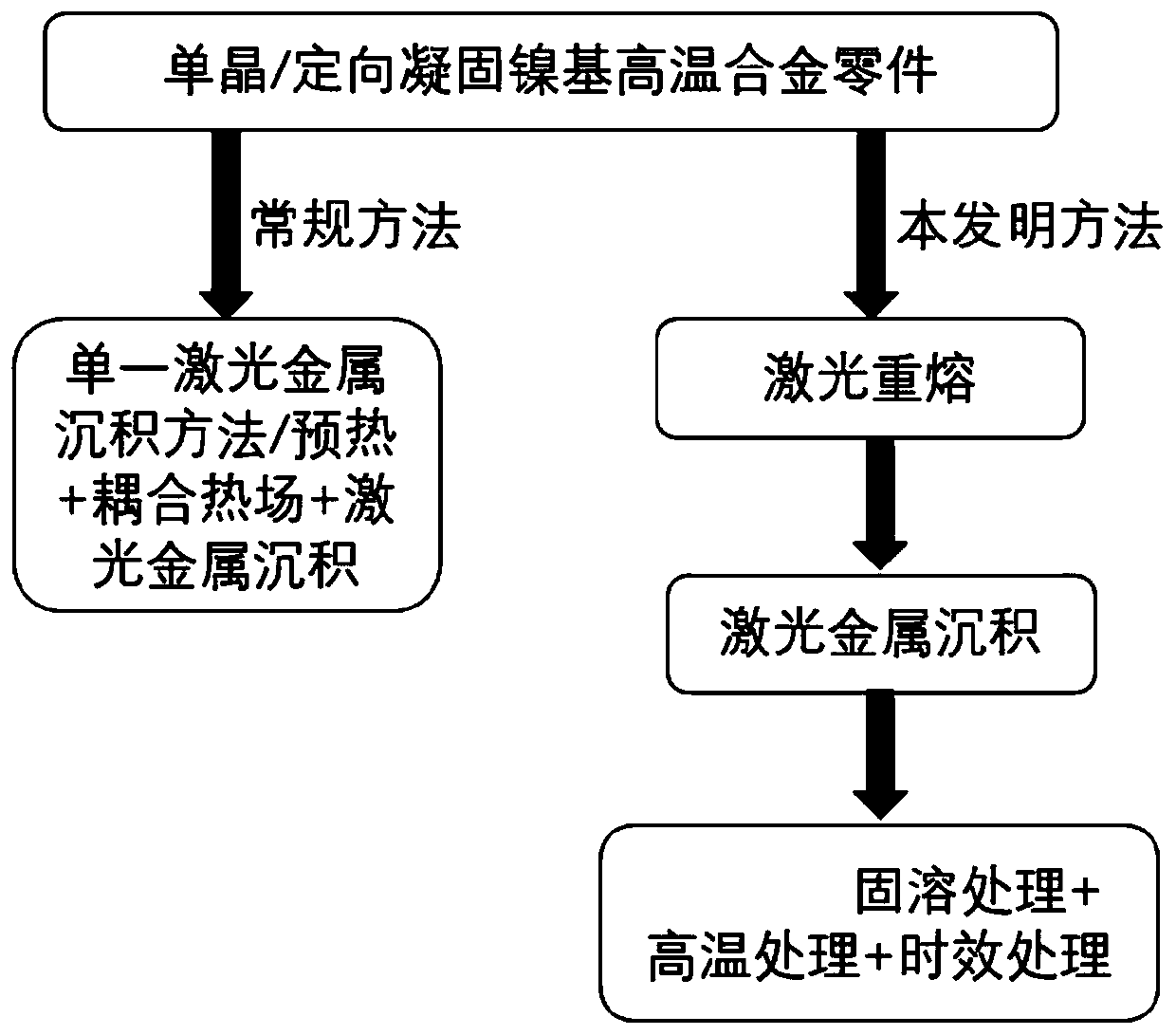

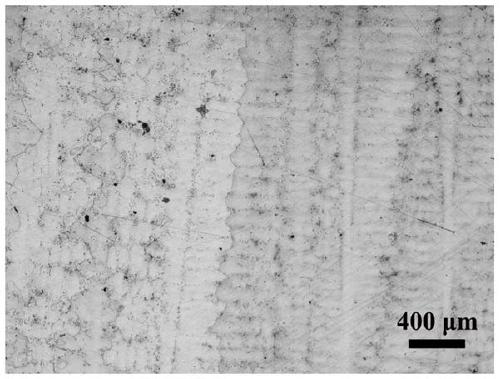

Repair method of single crystal/directional solidified nickel-based high-temperature alloy and application of repair method

ActiveCN110344049AInhibition of hot cracksInhibitionAdditive manufacturing apparatusIncreasing energy efficiencyMetal machiningSingle crystal

The invention relates to the field of metal machining, and particularly discloses a repair method of a single crystal / directional solidified nickel-based high-temperature alloy and application of therepair method. The method comprises the following steps that 1, a transition layer is formed on the surface of a to-be-repaired part of the single crystal / directional solidified nickel-based high-temperature alloy through a thermal conductance type melting mode; and 2, laser metal deposition treatment is performed on the transition layer to form a deposition layer, wherein the laser peak power ofthe laser metal deposition is 600 W-1200 W, the laser peak valley power is 50 W-150 W, the ratio of the laser peak power duration to the laser peak valley power duration is 1:4 to 3:2, and the laser frequency is 50 Hz-250 Hz. According to the repair method and the application, the method is simple to operate and remarkable in effect, compared with a traditional repair method, the method is beneficial to simultaneously guarantee the inhibition of thermal cracks and the continuous growth of columnar crystals, so that the production period is reduced.

Owner:TSINGHUA UNIV

Laser metal deposition cladding of weld seams in automotive parts

ActiveUS20150273629A1Improve bindingEfficient and cost-effectiveElectric discharge heatingPhosphatisationMotor vehicle partWeld seam

A part, such as an automotive part, is provided. The part includes at least two work pieces which are joined together at a weld seam. The weld seam has a laser metal deposition layer with at least one of nickel and iron, and the laser metal deposition layer is substantially entirely free of silicate islands. The part further includes a painted, phosphate or electrocoated coating which is bonded with at least a portion of the laser metal deposition layer of the weld seam.

Owner:MAGNA INTERNATIONAL INC

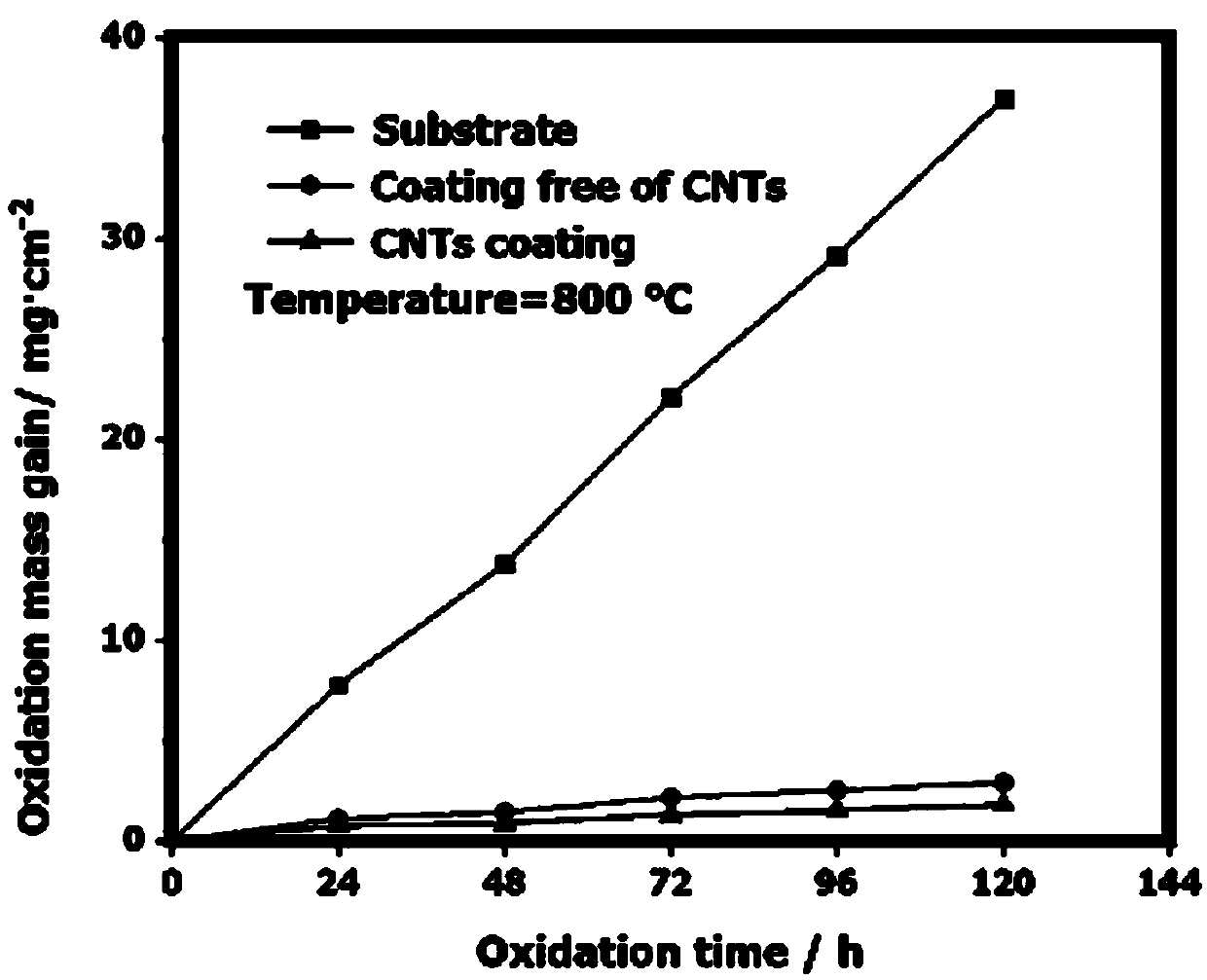

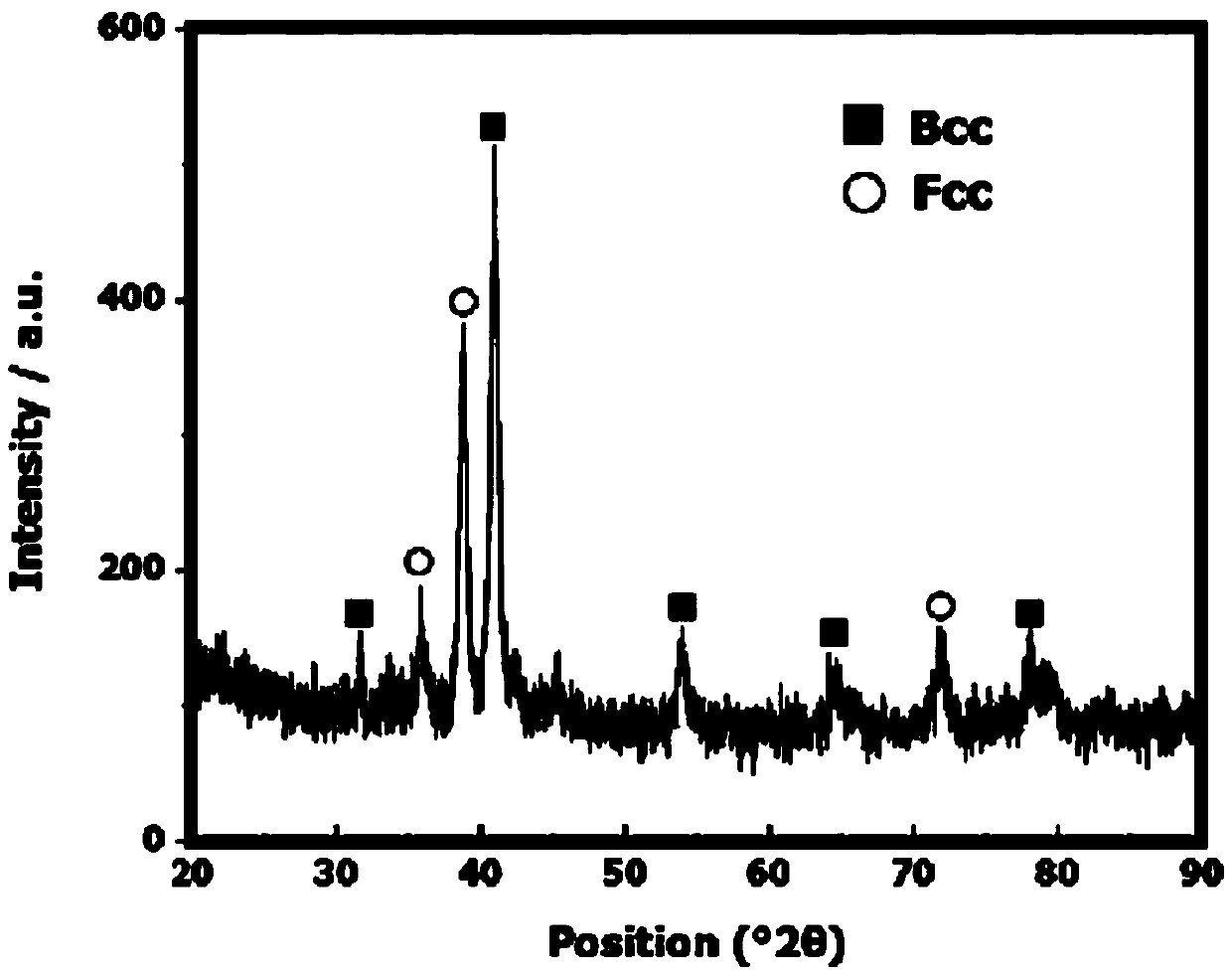

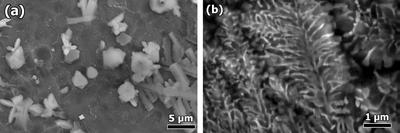

Method for preparing CNTs (carbon nanotubes) reinforced high-entropy alloy laser deposition composite material

ActiveCN110438493AFully protectedHigh hardnessAdditive manufacturing apparatusMetallic material coating processesHigh entropy alloysArgon atmosphere

The invention discloses a method for preparing a CNTs (carbon nanotubes) reinforced high-entropy alloy laser deposition composite material. According to the method, FeCoCrAlCu-SiB6-(Ni / Ag coated-CNTs)mixed powder is deposited on the surface of a TA2 titanium alloy by laser melting with a coaxial powder feeding method in argon atmosphere, an LMD (laser metal deposition) coating is formed, the coating has bcc and fcc structures, hardness of the bcc structure is higher and toughness of the fcc structure is better; a large quantity of CNTs are attached to the surface of ceramic crystallization phase in the coating, growth of the crystallization phase can be effectively inhibited, the organization structure is refined, and therefore, the structure property of the prepared composite material isremarkably enhanced; a high-temperature oxidation test result indicates that high-temperature oxidation property of the CNTs reinforced LMD coating is obviously better than that of a FeCoCrAlCu-SiB6laser deposition layer and the TA2 titanium alloy base material without addition of CNTs. The CNTs reinforced high-entropy alloy laser deposition composite material with compact organization structureand good high-temperature oxidizability can be obtained.

Owner:SHANDONG JIANZHU UNIV

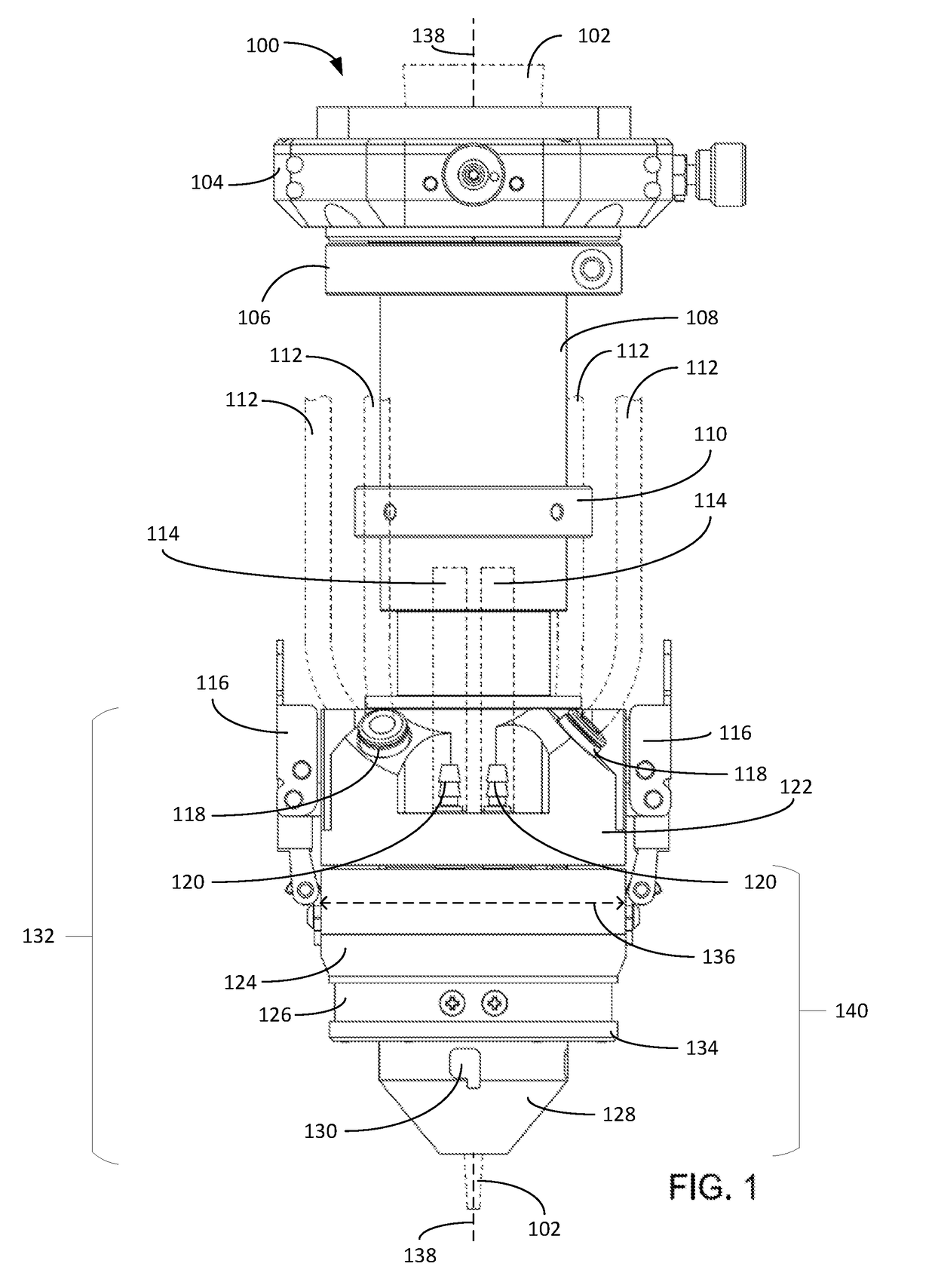

Laser metal deposition head

ActiveUS10875123B2Additive manufacturing apparatusIncreasing energy efficiencyEngineeringMechanical engineering

Aspects of the present disclosure relate to improved laser metal deposition heads. Various embodiments may include a main body, a nozzle seat, a powder flow guide, an inner nozzle, an outer nozzle, and a coolant sleeve. In some embodiments, powder inlets in the main body are angled relative to a primary axis of the laser metal deposition head. In some embodiments, the nozzle seat includes a plurality of powder distribution channels that are also angled relative to the primary axis of the laser metal deposition head.

Owner:FORMALLOY LLC

Brake disc and manufacturing method thereof

ActiveUS10260585B2Thermal strain generated during welding is suppressedReduce thicknessAdditive manufacturing apparatusBraking discsEngineeringMechanical engineering

A brake disc of the present invention is a brake disc that stops the rotation of an axle when a brake pad is pressed on a surface of the brake disc, including a disc main body that is attached to a rotary body integrally rotating with the axle; and a plurality of build-up layers laminated on a surface of the disc main body, in which the build-up layers are laminated on the surface of the disc main body by means of laser metal deposition welding.

Owner:RAILWAY TECH RES INST +1

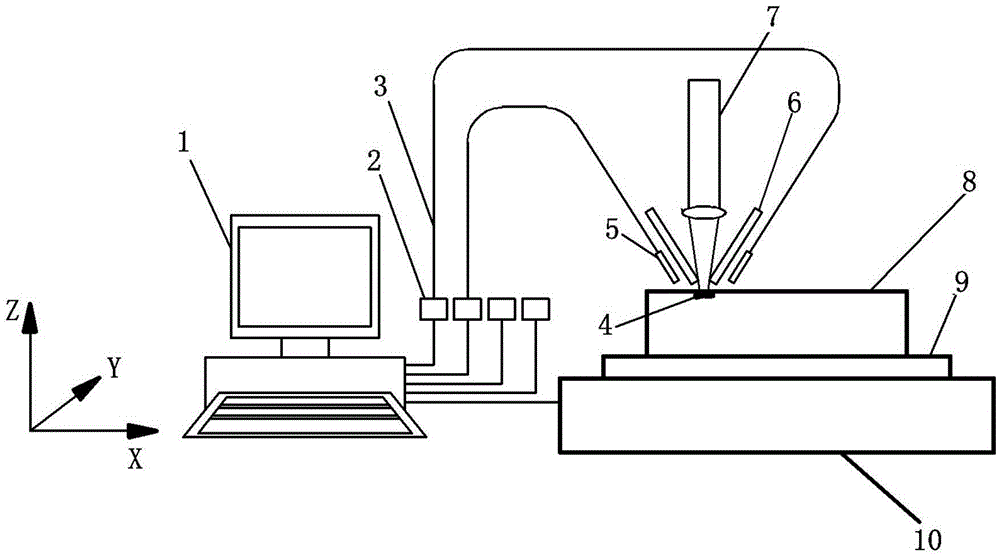

Device for repairing gears by means of laser cladding

ActiveCN108866546AQuality improvementImprove efficiencyMetallic material coating processesLaser processingProgrammable logic controller

The invention discloses a device for repairing gears by means of laser cladding, belonging to the field of laser processing. The device comprises a three-dimensional mobile platform, a programmable logic controller (PLC) system, a laser metal deposition system, a fixture and a motor. When the device is in use, the gear to be repaired is fixed on the fixture, and the broken teeth of the gear are enabled to be placed on a horizontal plane by controlling the motor. The device has the advantages of being simple in structure and convenient to operate, improving gear repairing quality and efficiency, having higher flexibility, and being capable of clamping the gears with different inner hole sizes.

Owner:JIANGSU UNIV

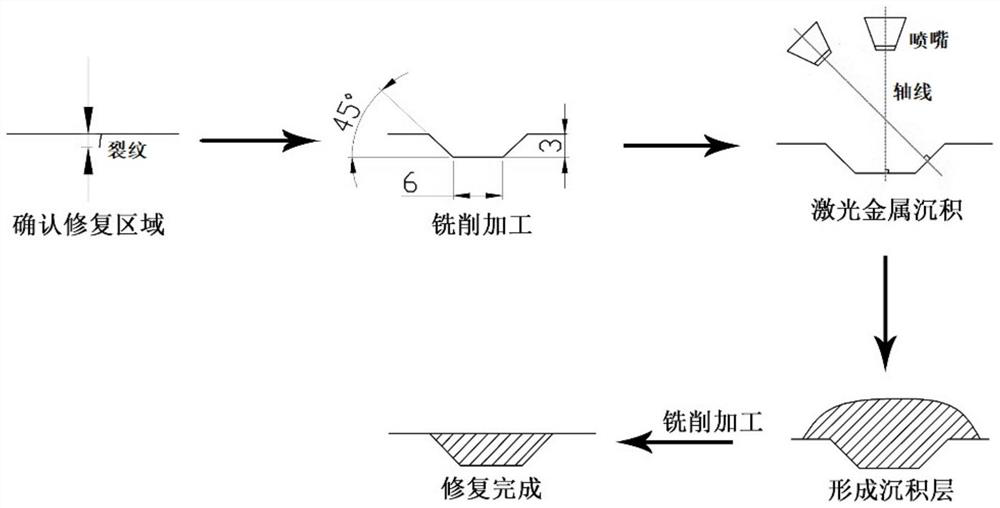

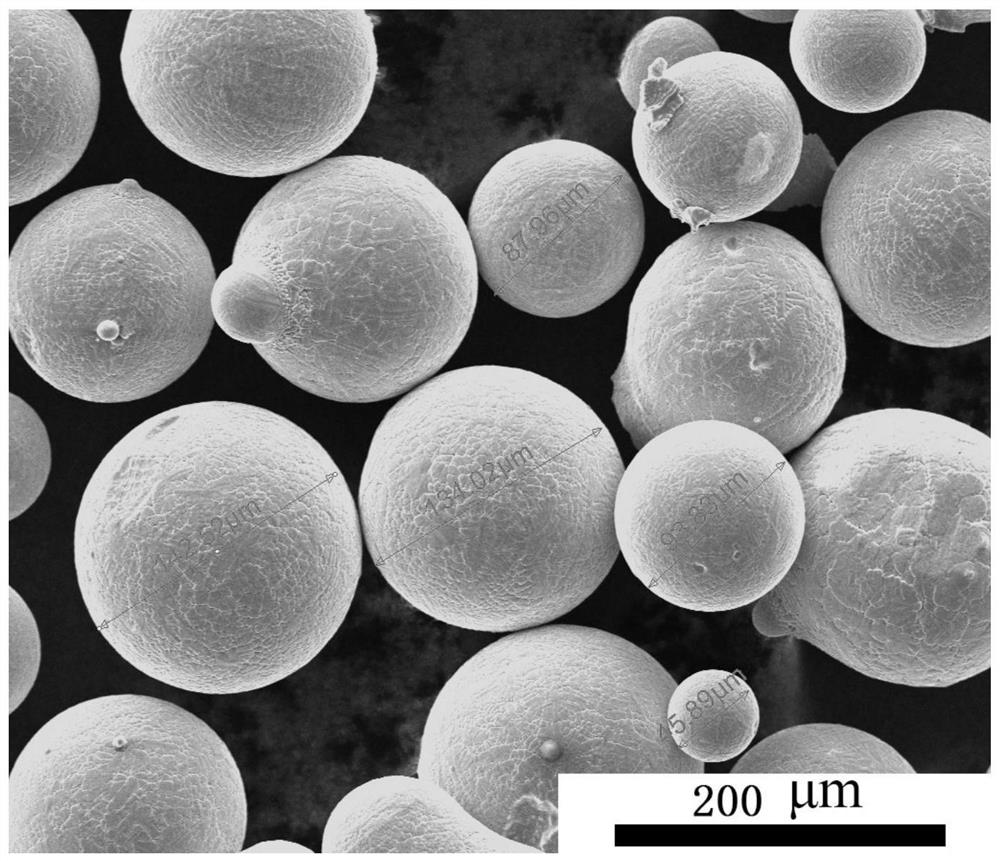

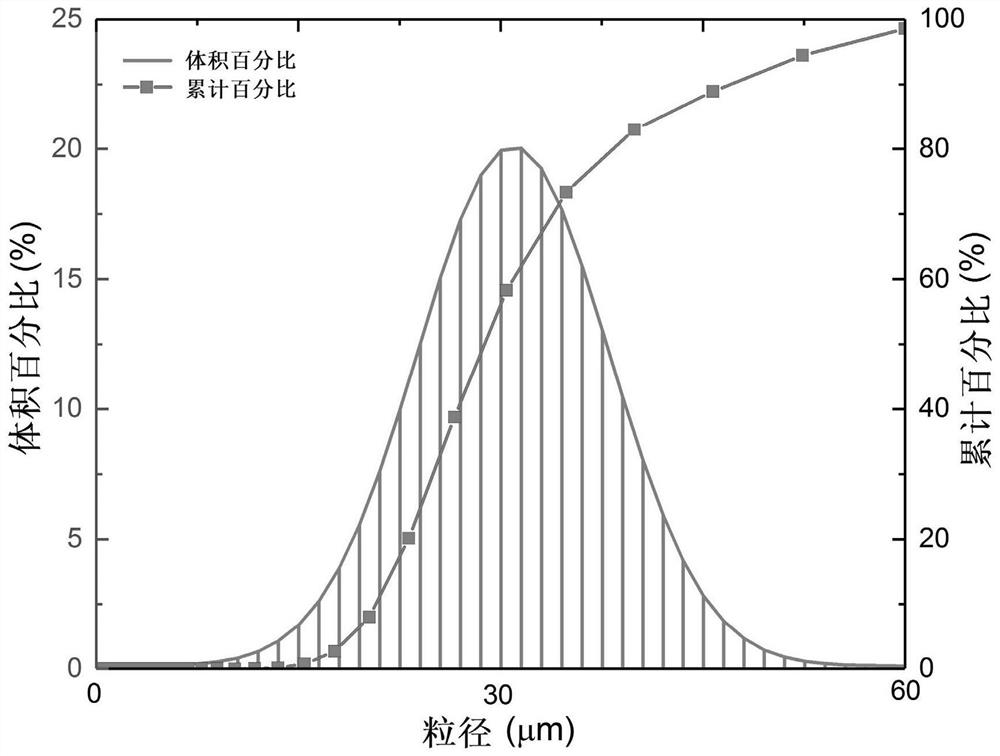

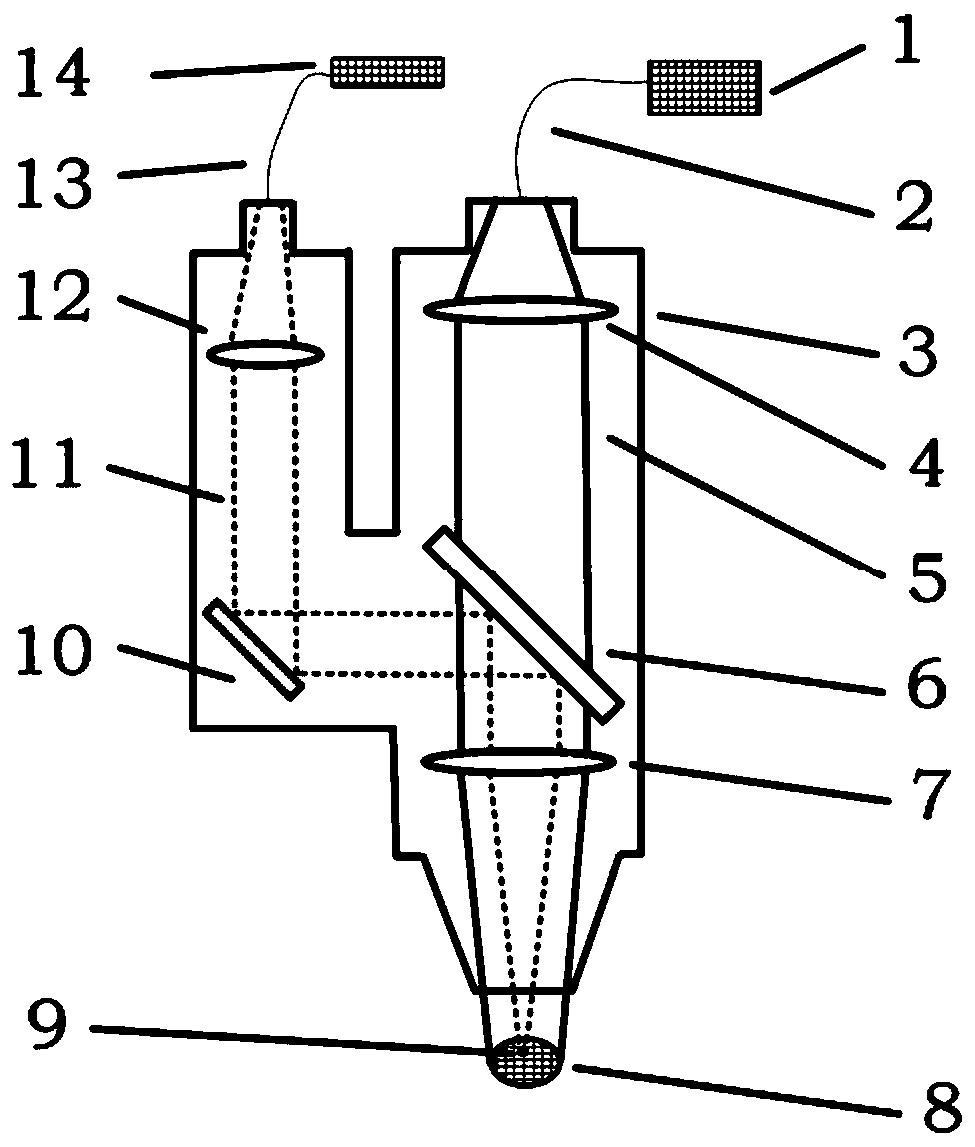

Laser additive repairing method for H13 steel mold

ActiveCN114226751AHigh strengthHigh hardnessAdditive manufacturing apparatusIncreasing energy efficiencyHardnessLaser additive manufacturing

The invention discloses a laser additive repairing method for an H13 steel mold. The laser additive repairing method comprises the following steps that (1) a to-be-repaired area of the H13 steel mold is pretreated; (2) spherical H13 steel mixed powder with different particle size distribution is adopted for conducting laser metal deposition on the to-be-repaired area through laser additive manufacturing, the position and angle of a nozzle are dynamically adjusted according to the characteristics of the to-be-repaired area, and laser power is dynamically adjusted according to the number of deposition layers; and (3) milling a deposition layer formed by laser metal deposition. By means of the method, laser additive repairing can be conducted on various surfaces such as the plane, the inclined face and the arc face of the H13 steel mold, the strength, hardness and impact toughness of a repairing area are large, and good metallurgical bonding is formed between the repairing area and an H13 steel mold base body.

Owner:SOUTH CHINA UNIV OF TECH +1

Device and method for refining structure crystalline grains in metal additive manufacturing process

ActiveCN110802229AGuaranteed simultaneityGrain refinementAdditive manufacturing apparatusIncreasing energy efficiencyPhysical chemistryErbium lasers

The invention provides a device and method for refining structure crystalline grains in the metal additive manufacturing process. The device comprises a main laser device and an auxiliary laser device. A main laser path and an auxiliary laser path transmit lasers to the same concentration lens through a light combination lens. The concentration lens generates a composite laser spot composed of a main laser spot and an auxiliary laser spot. The auxiliary laser spot is smaller than that of the main laser spot and can move in the main laser spot. By the adoption of the device and method for refining the structural crystalline grains in the metal additive manufacturing process, a bath is formed through the main laser spot, a key hole is formed through the auxiliary laser spot, the key hole ismade to move in a specific manner to achieve the function of stirring the bath, and therefore the structure crystalline grains are refined; the depth and shape of the key hole can be adjusted by adjusting the parameter of the auxiliary laser; the device and method for refining the structure crystalline grains in the metal additive manufacturing process have no limitation to matrix and powder adopted in the laser metal deposition process and are suitable for formation motion in any form, the situation that in the process of refining the structural crystalline grains, after one cladding layer isobtained, the track is repeated is avoided, and high efficiency is achieved.

Owner:XI AN JIAOTONG UNIV

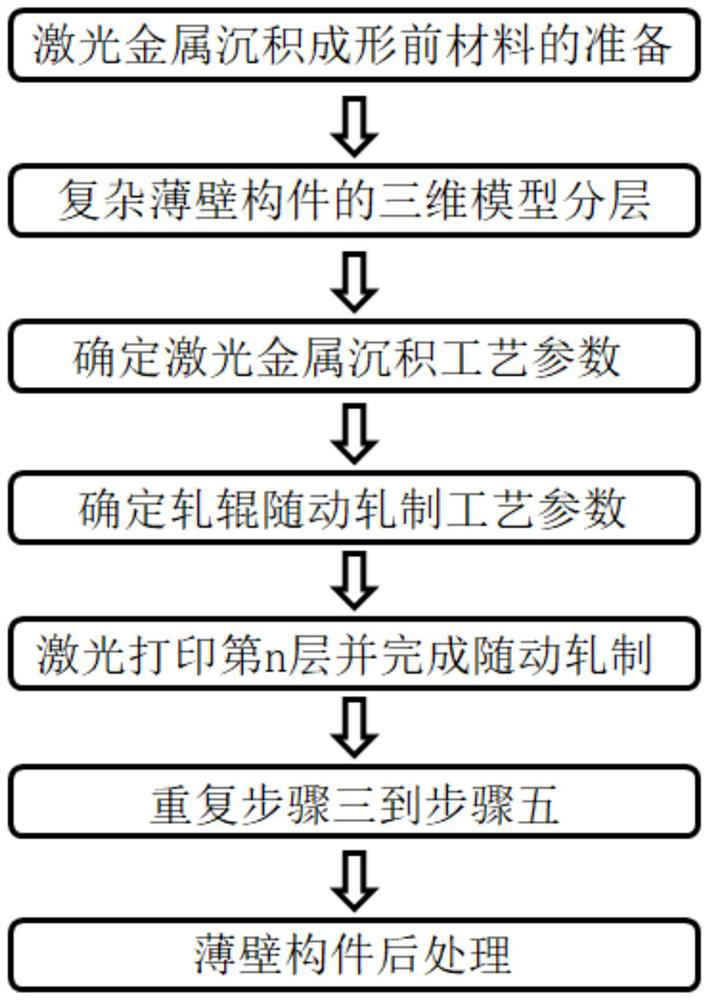

Method for preparing complex thin-wall component through laser metal deposition and follow-up rolling

ActiveCN113732310ASolve quality problemsSolve the accuracy problemAdditive manufacturing apparatusRoll force/gap control deviceLaser additive manufacturingLaser beams

The invention belongs to the technical field of laser additive manufacturing, and provides a method for preparing a complex thin-wall component through laser metal deposition and follow-up rolling, which comprises the following steps of: preparing materials before laser metal deposition forming; layering a three-dimensional model of the complex thin-wall component; determining laser metal deposition process parameters; determining roll follow-up rolling process parameters; conducting laser printing on the nth layer, and completing follow-up rolling; repeating the step 3 to the step 5; and performing post-treatment on the thin-wall component. The method can solve problems that when an existing laser metal deposition technology is used for preparing a complex special-shaped thin-wall component, component deformation is caused by residual stress, and a laser beam cannot act on the end face of the component, and the problems that the surface quality is poor and the reliability is reduced due to convex-concave peaks caused by interlayer lap joint on the surface of the formed component, and secondary deformation is easily caused during subsequent machining or laser polishing treatment on the surface of the component.

Owner:DALIAN UNIV OF TECH

Metal deposition method and laser metal deposition apparatus

The invention provides a metal deposition method and a laser metal deposition apparatus. In the metal deposition method, a buildup is formed on a single crystal or directionally solidified crystal parent material such that the deposition part and the parent material are deposited in the same direction. In a deposition method of forming a buildup on a single crystal or directionally solidified crystal parent material, metal deposition is performed from an extension in a preferential growth orientation of parent material crystals while forcedly cooling a portion of the parent material somewhat below a processed surface and beforehand giving a temperature gradient to the parent material so that a maximum temperature gradient is oriented along the preferential growth orientation of parent material crystals.

Owner:HITACHI LTD

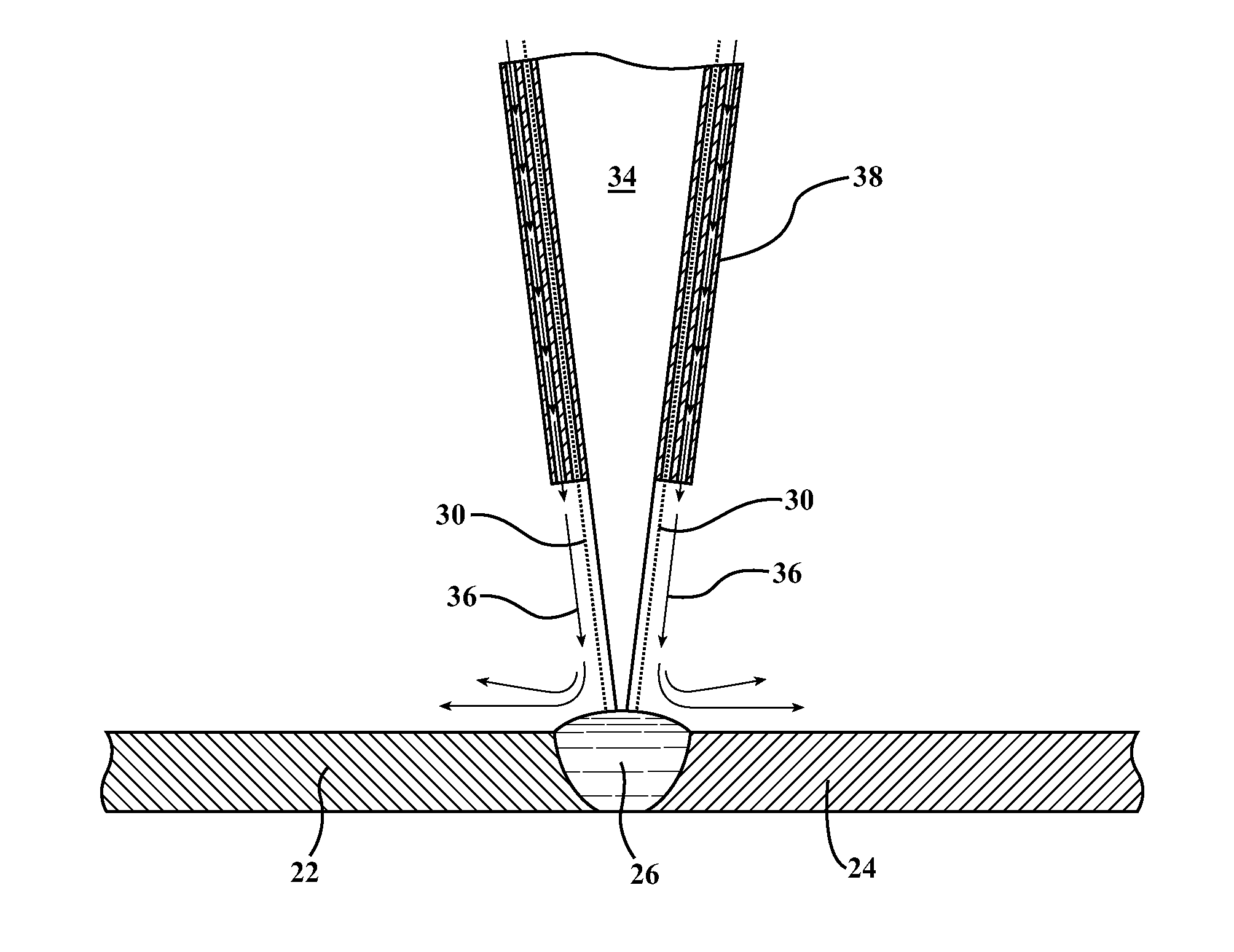

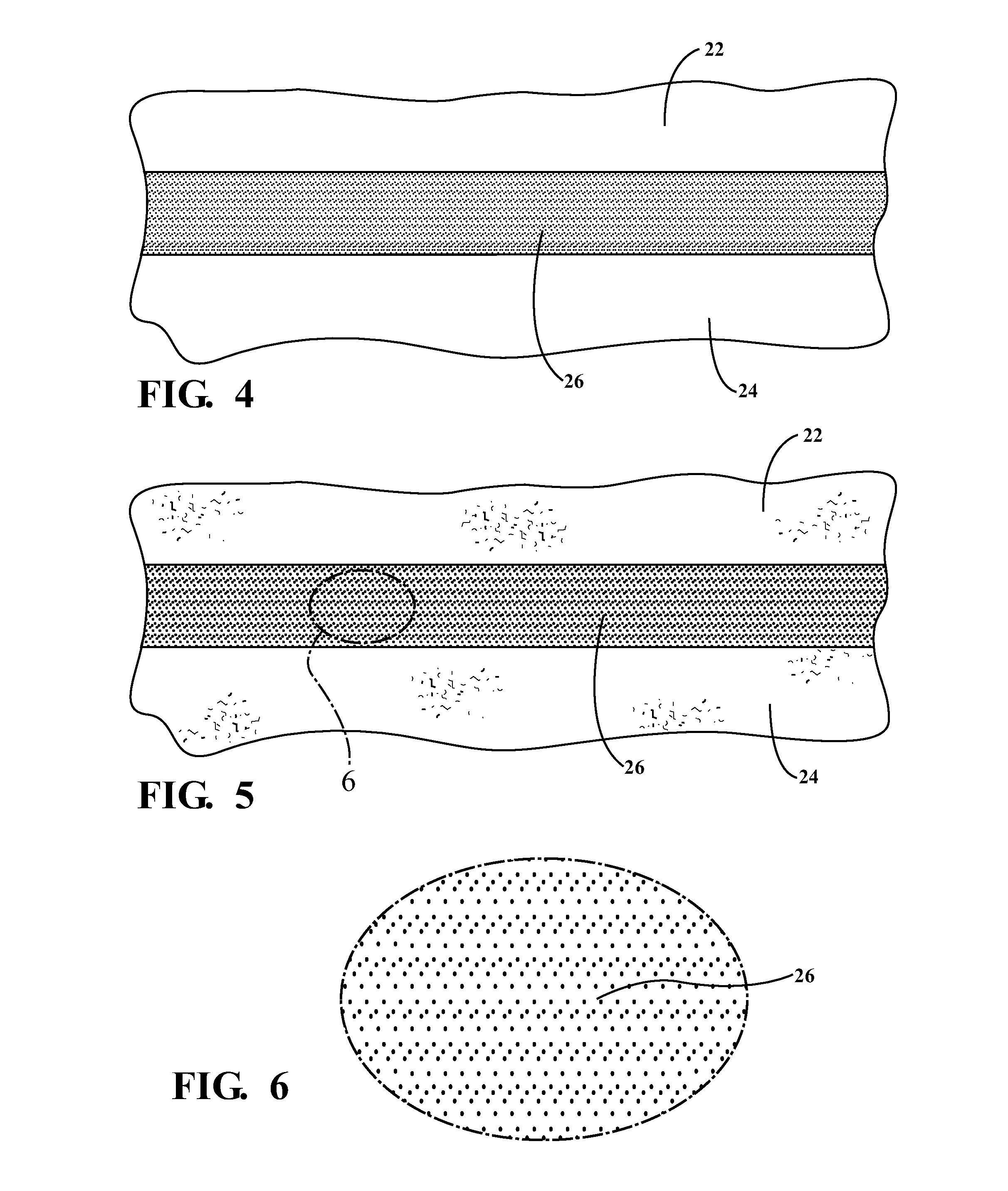

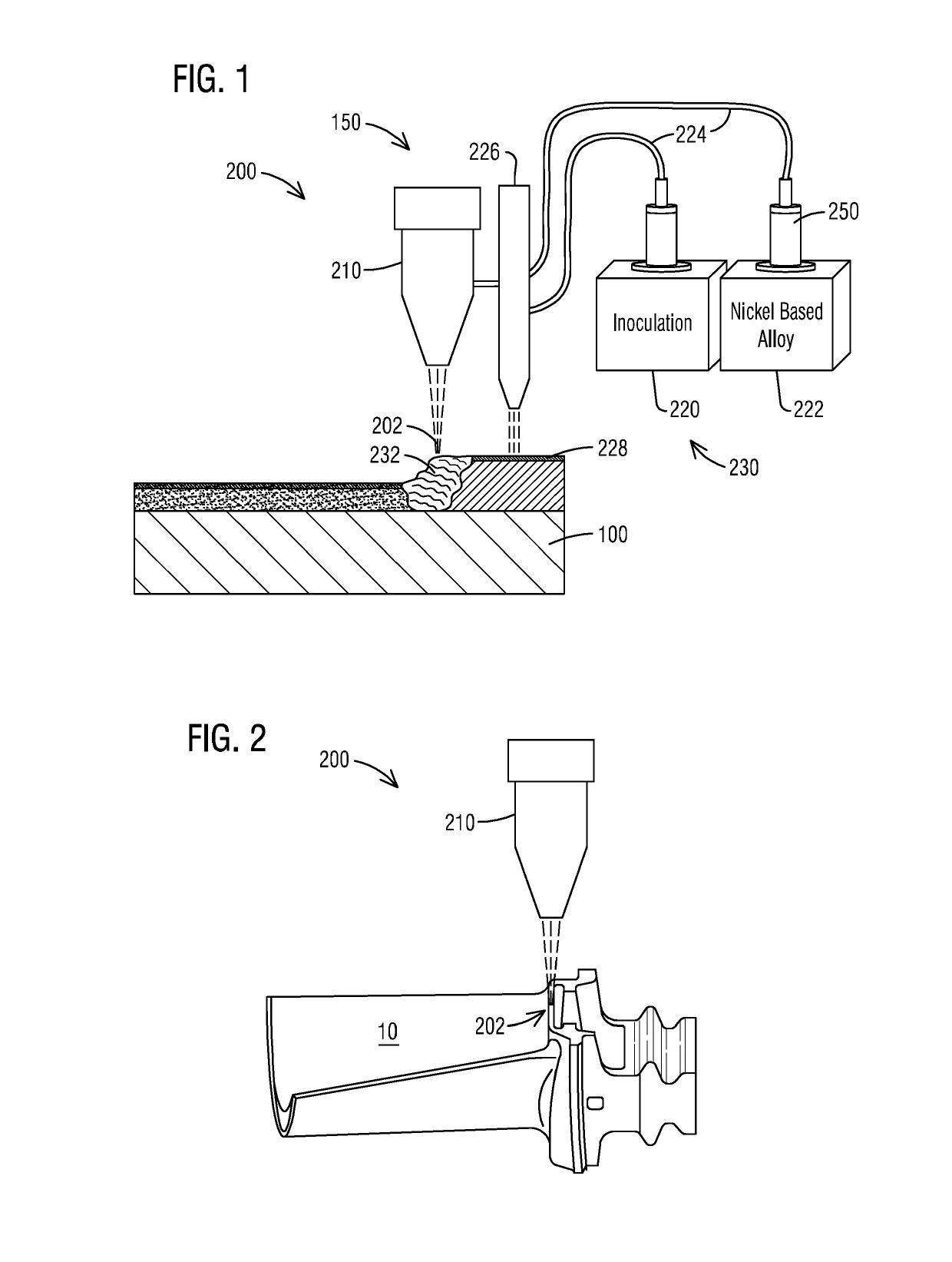

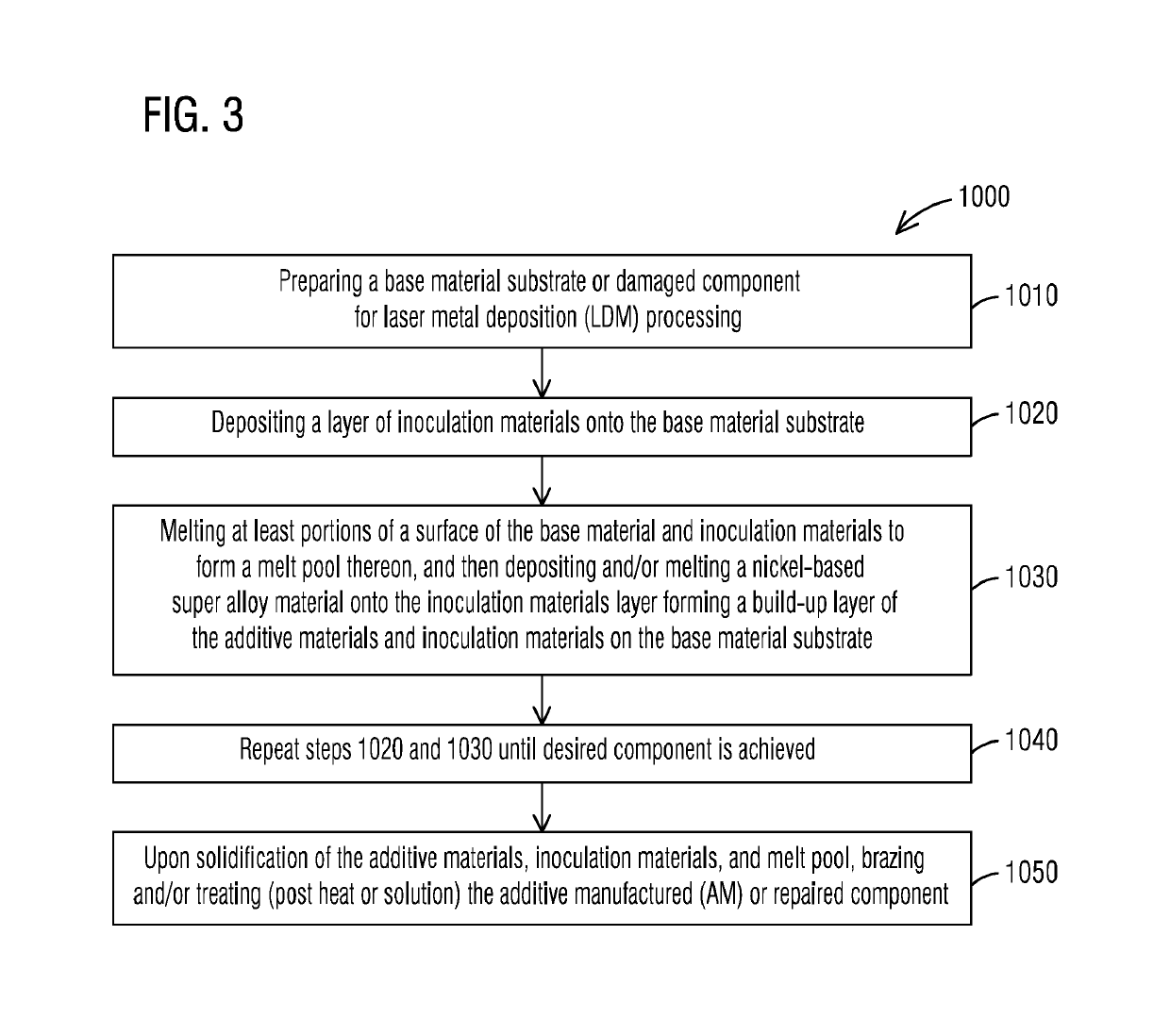

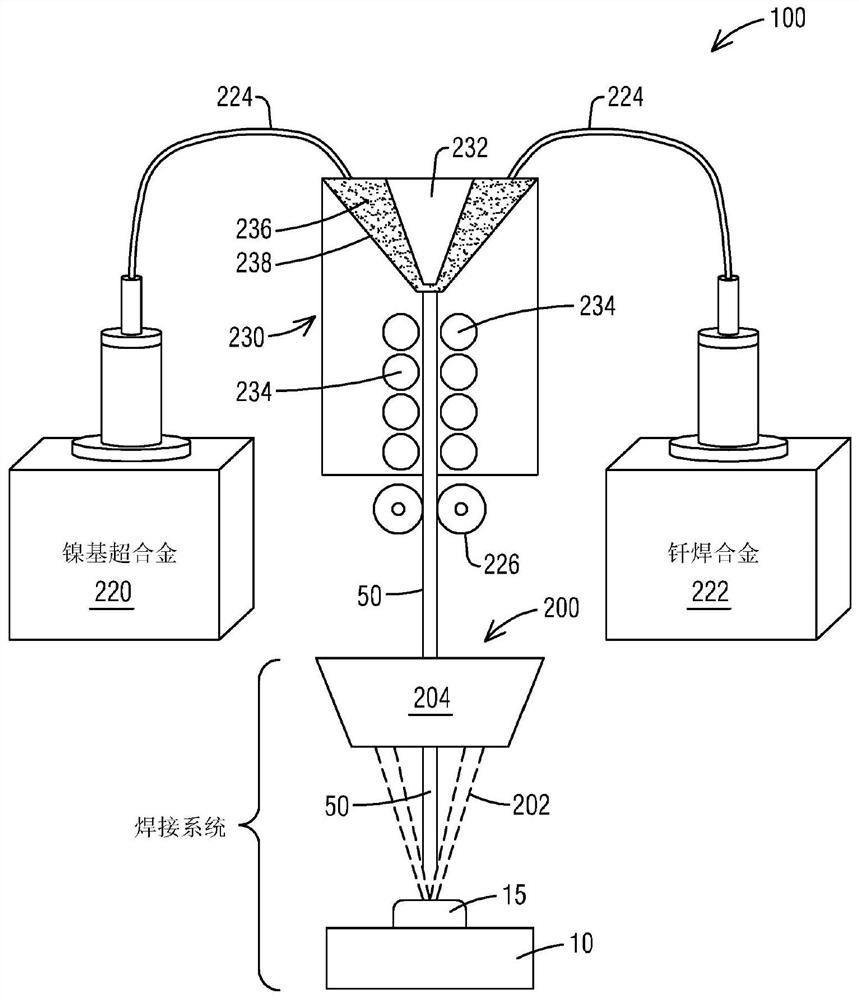

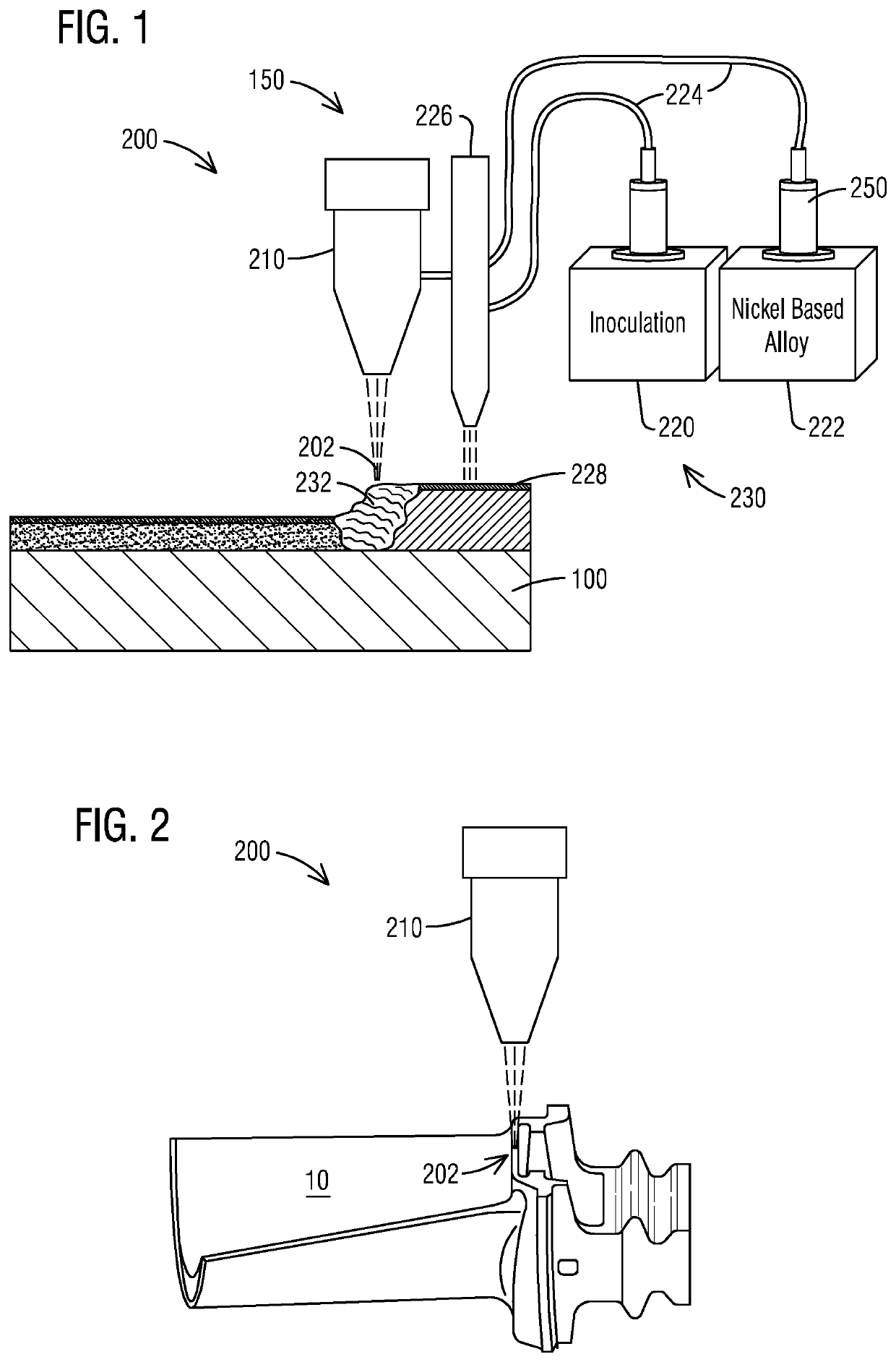

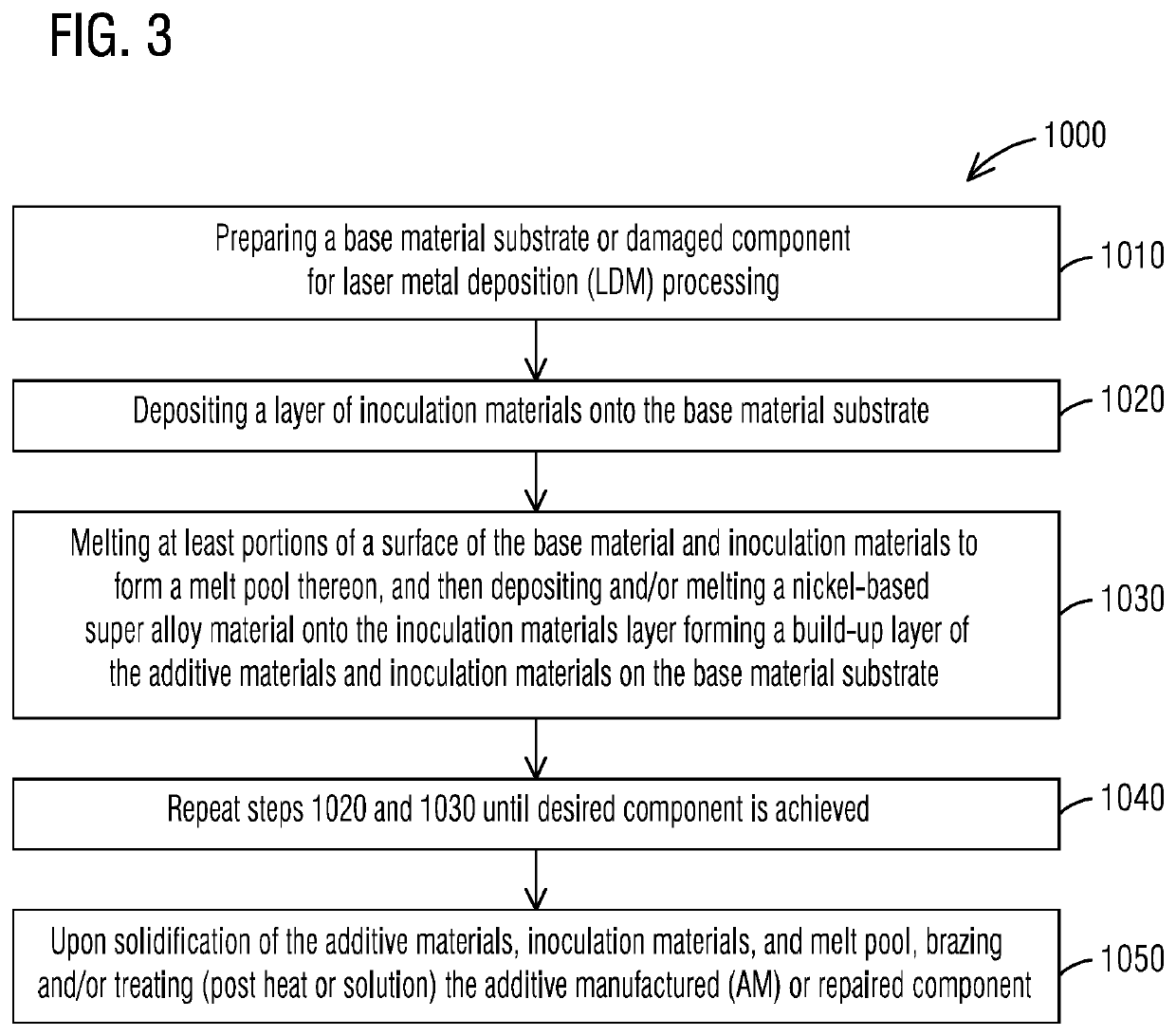

Laser metal deposition with inoculation

Systems and methods for additively manufacturing or repairing a component from a base material. The system may include an inoculation source to direct inoculation materials and a laser metal deposition (LMD) system to direct laser energy during laser processing of additive materials deposited in a melt pool on the base material. The LMD system includes a laser energy source configured to direct laser energy towards the base material and inoculation materials to form the melt pool thereon and to process the deposited additive materials and inoculation materials to form layers on the base material upon solidification.

Owner:SIEMENS ENERGY INC

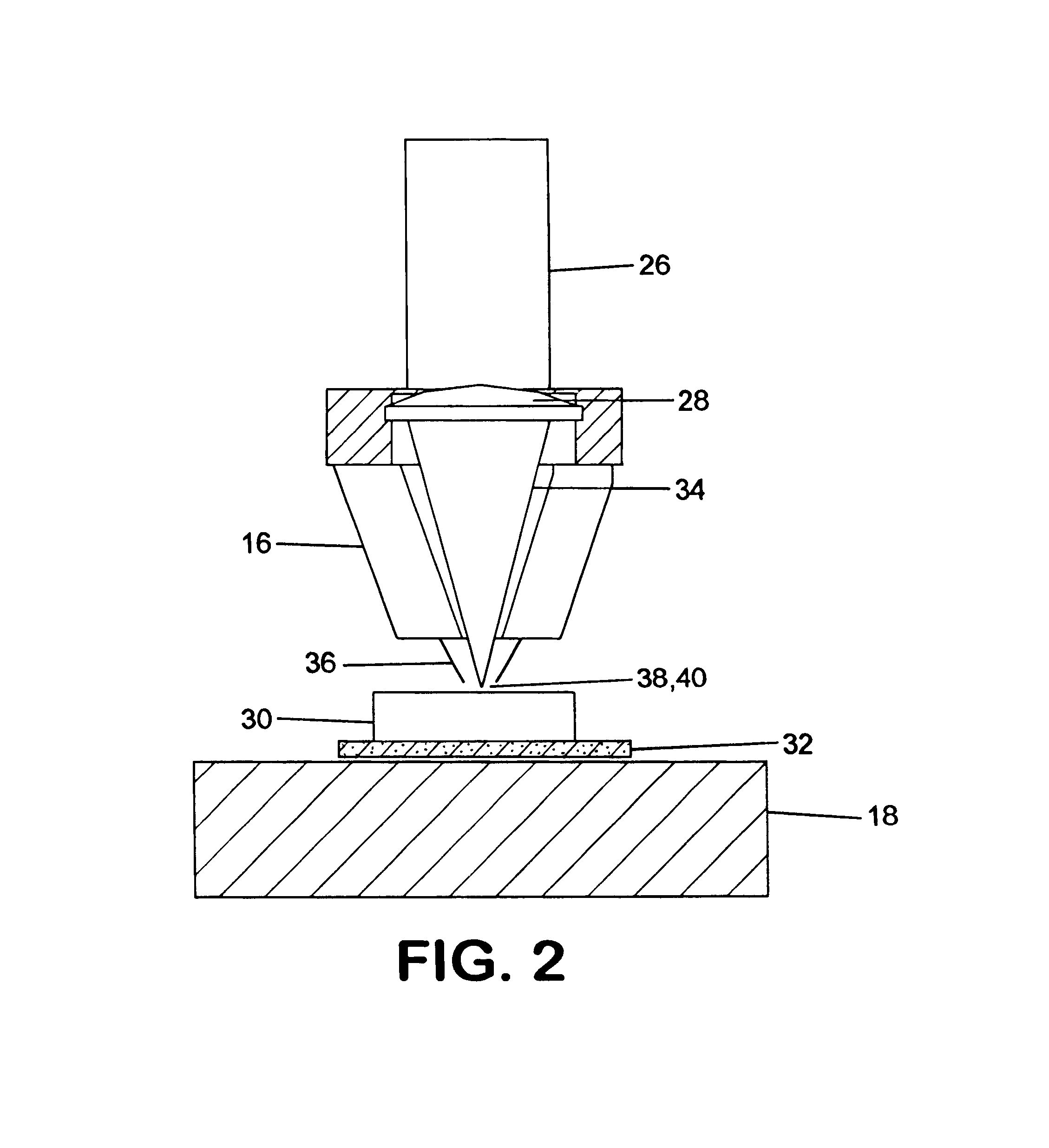

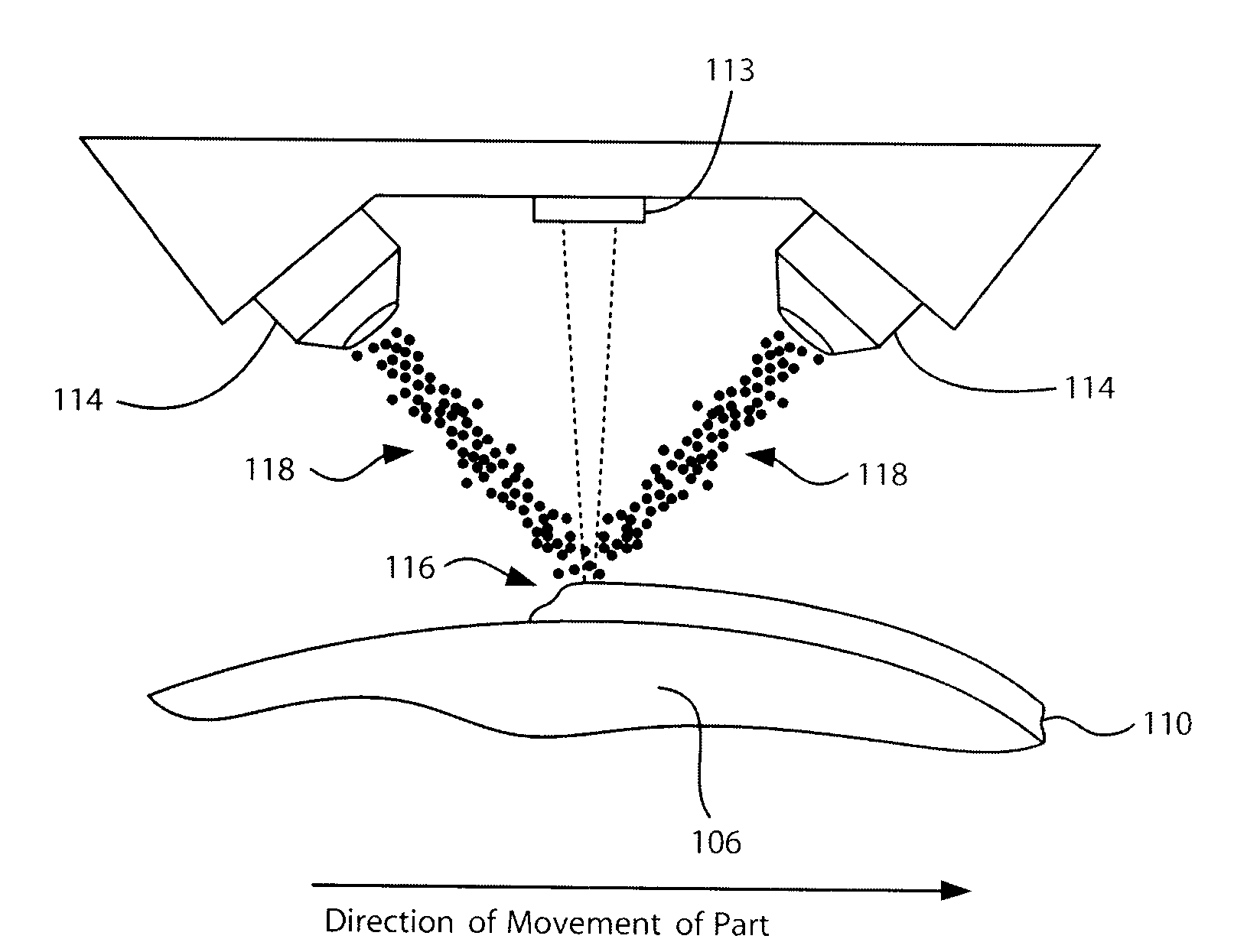

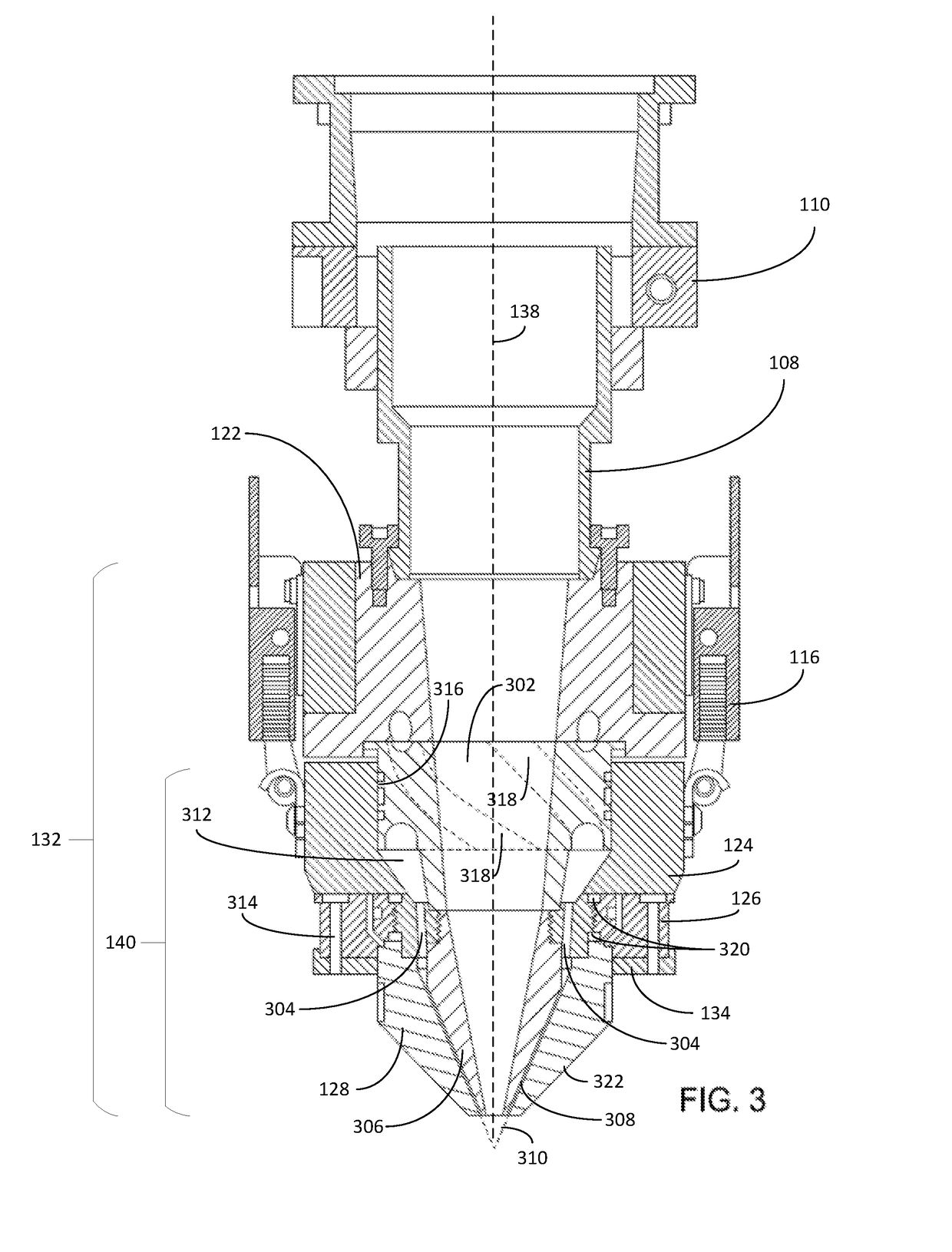

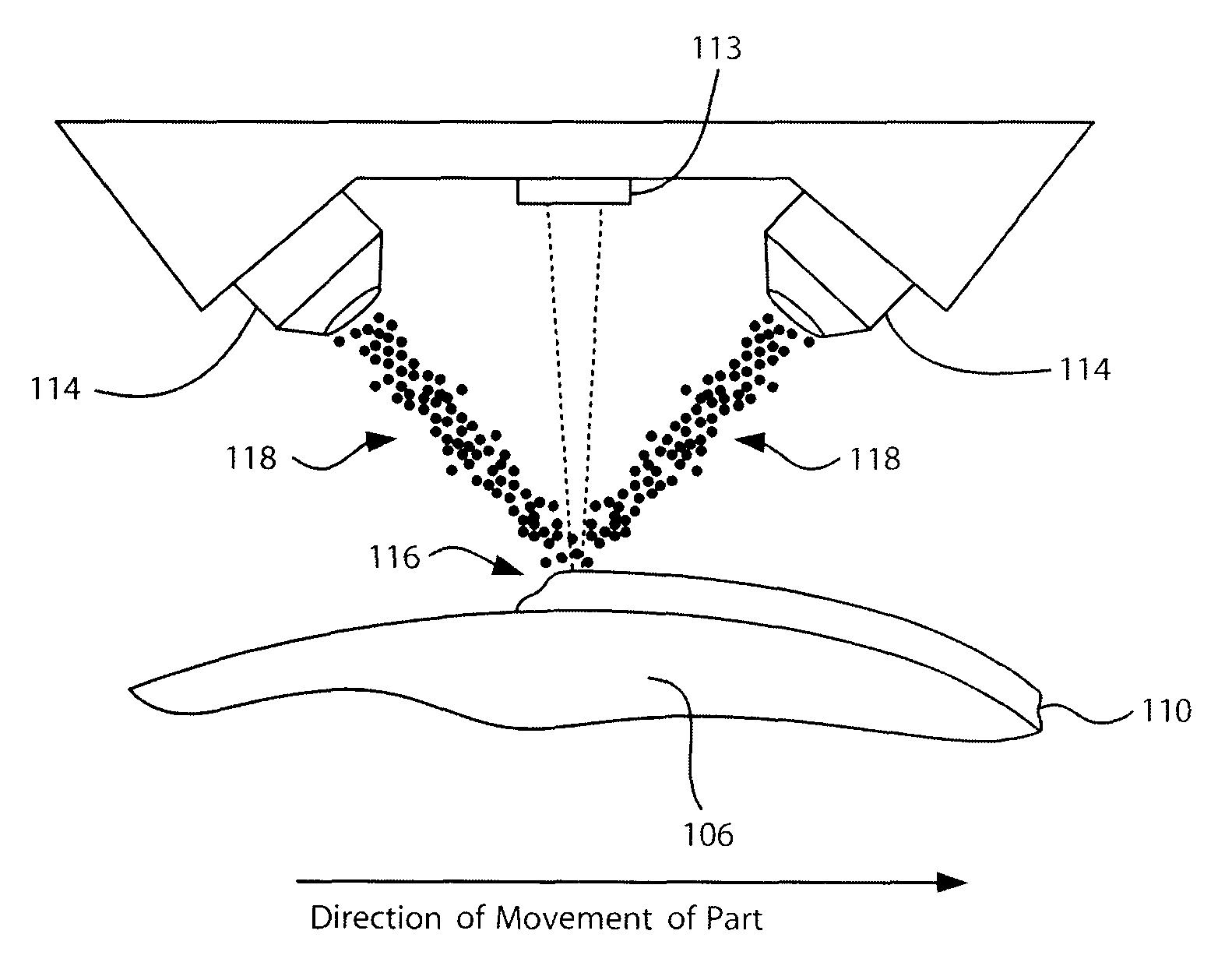

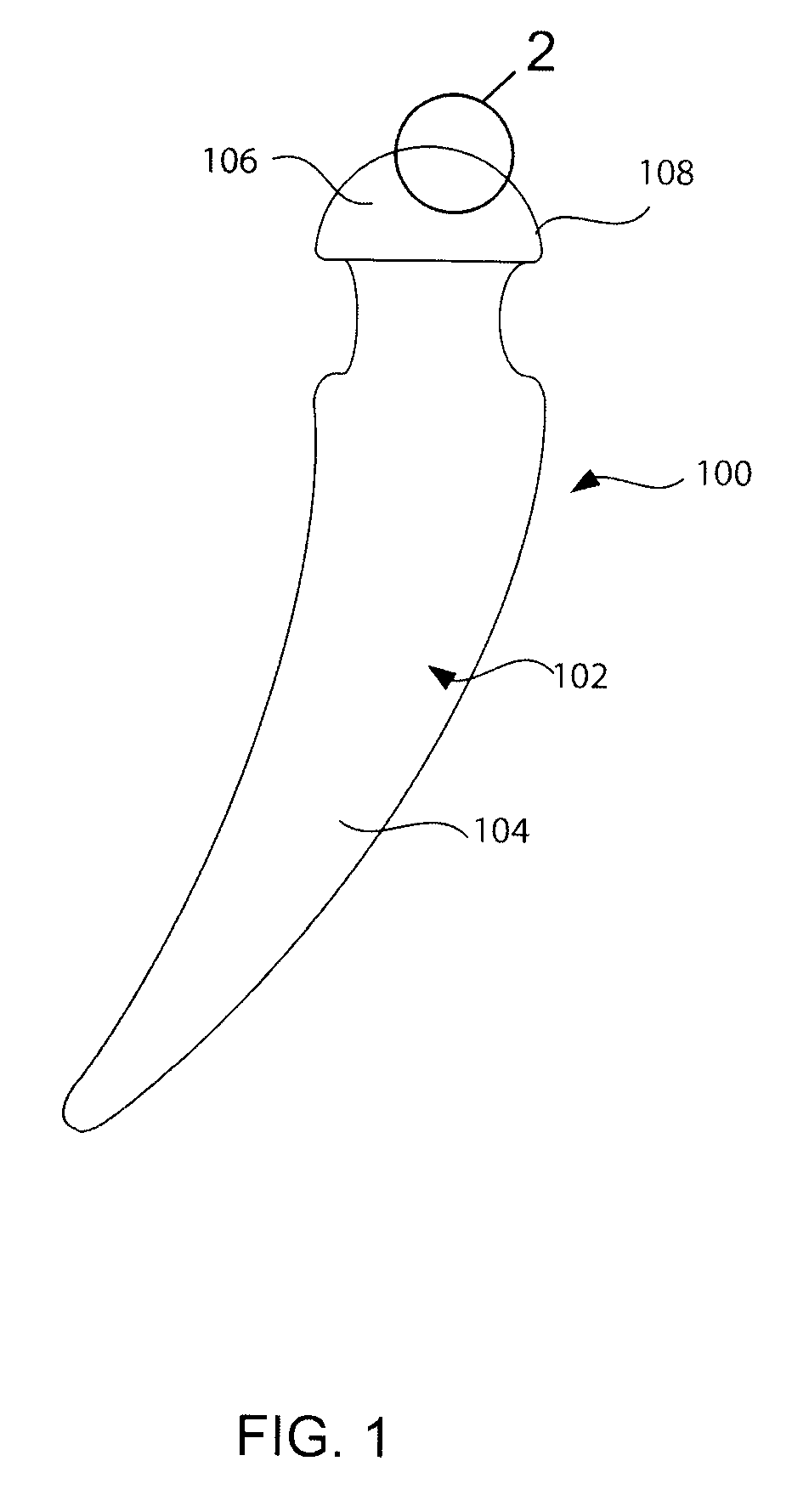

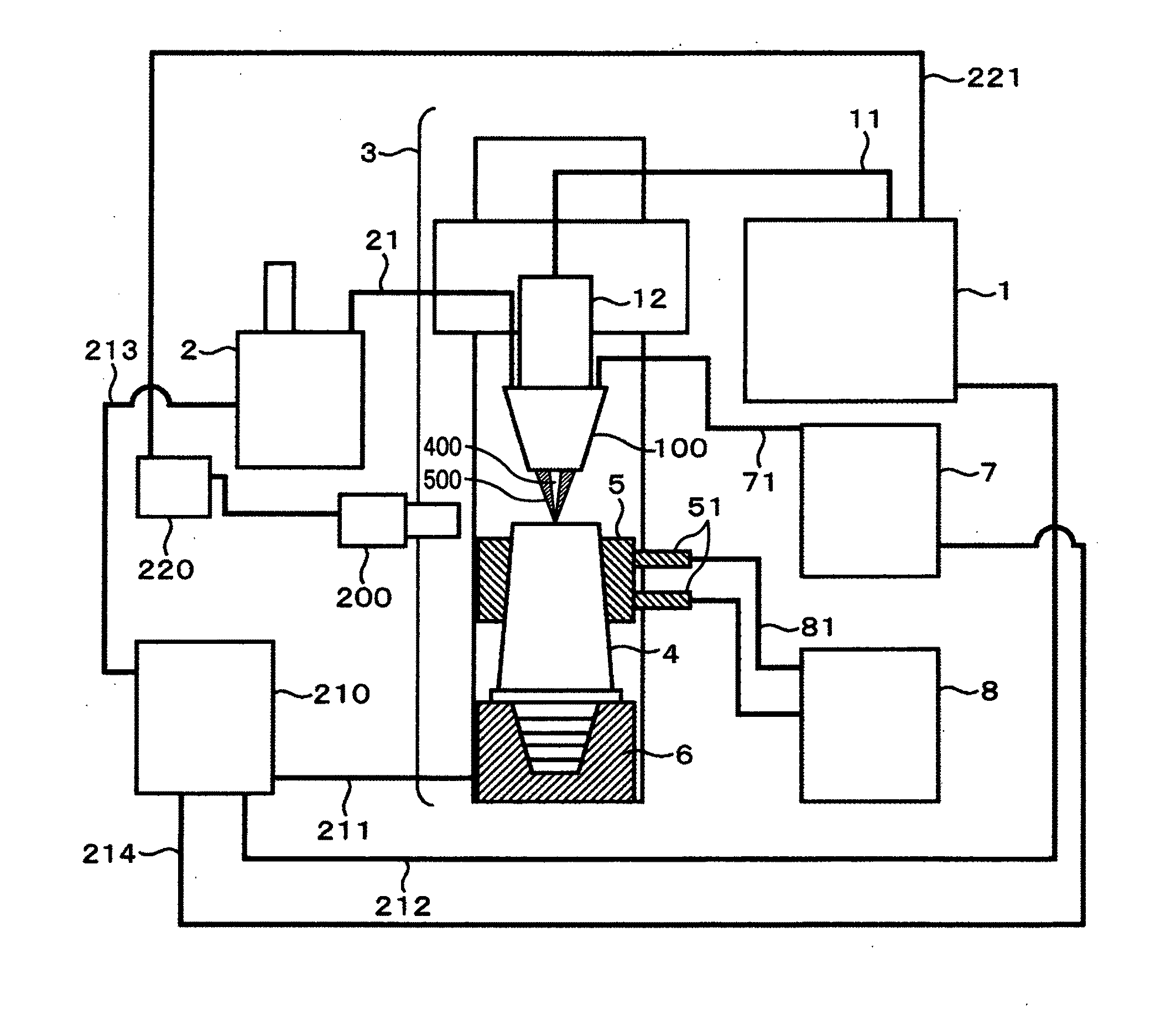

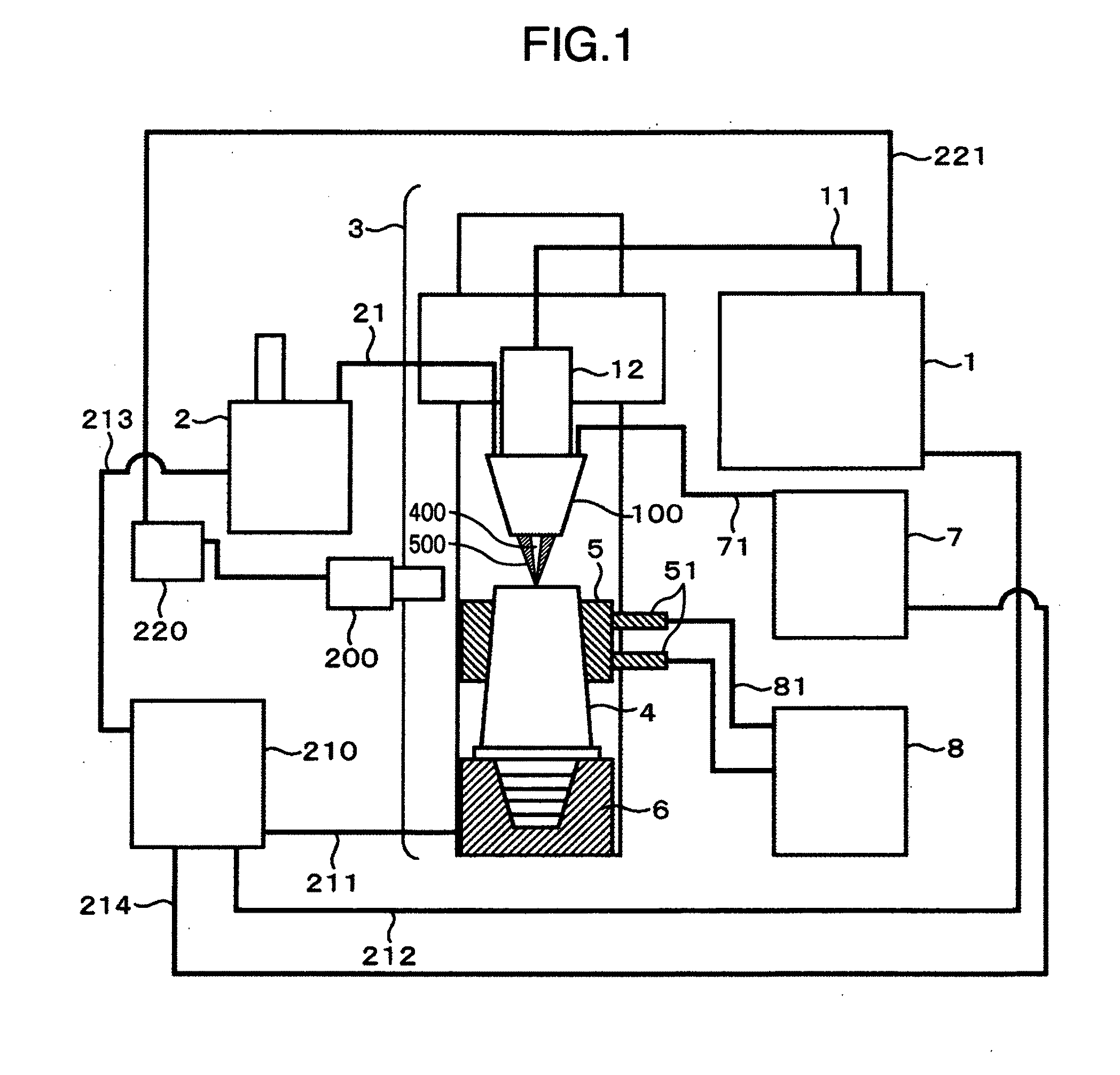

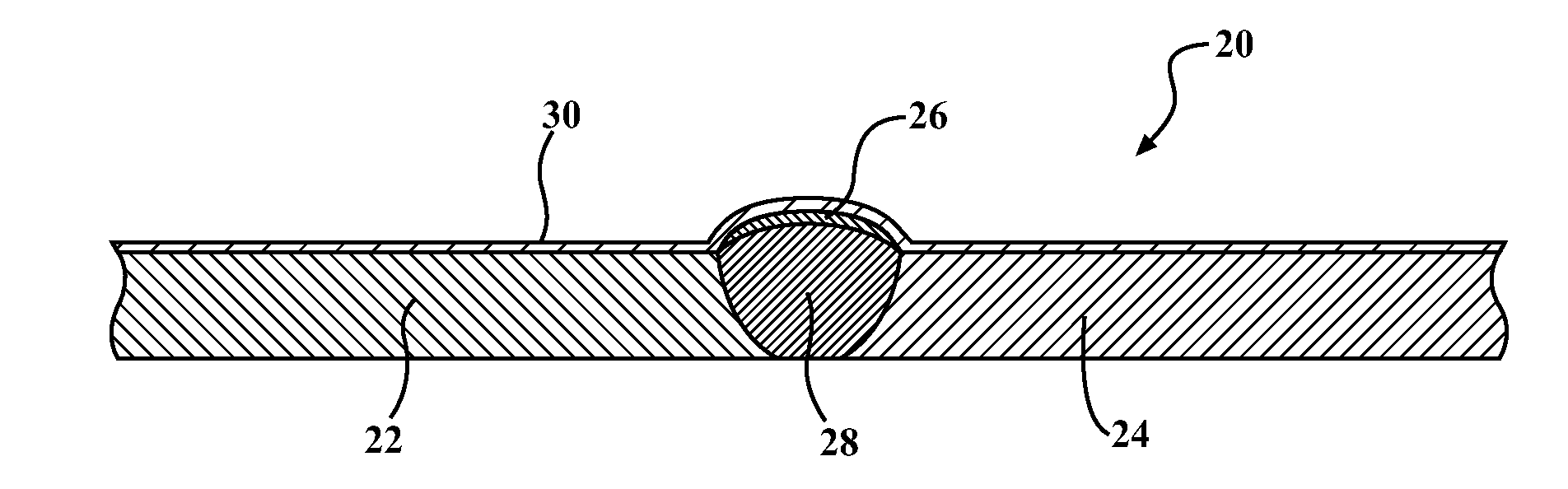

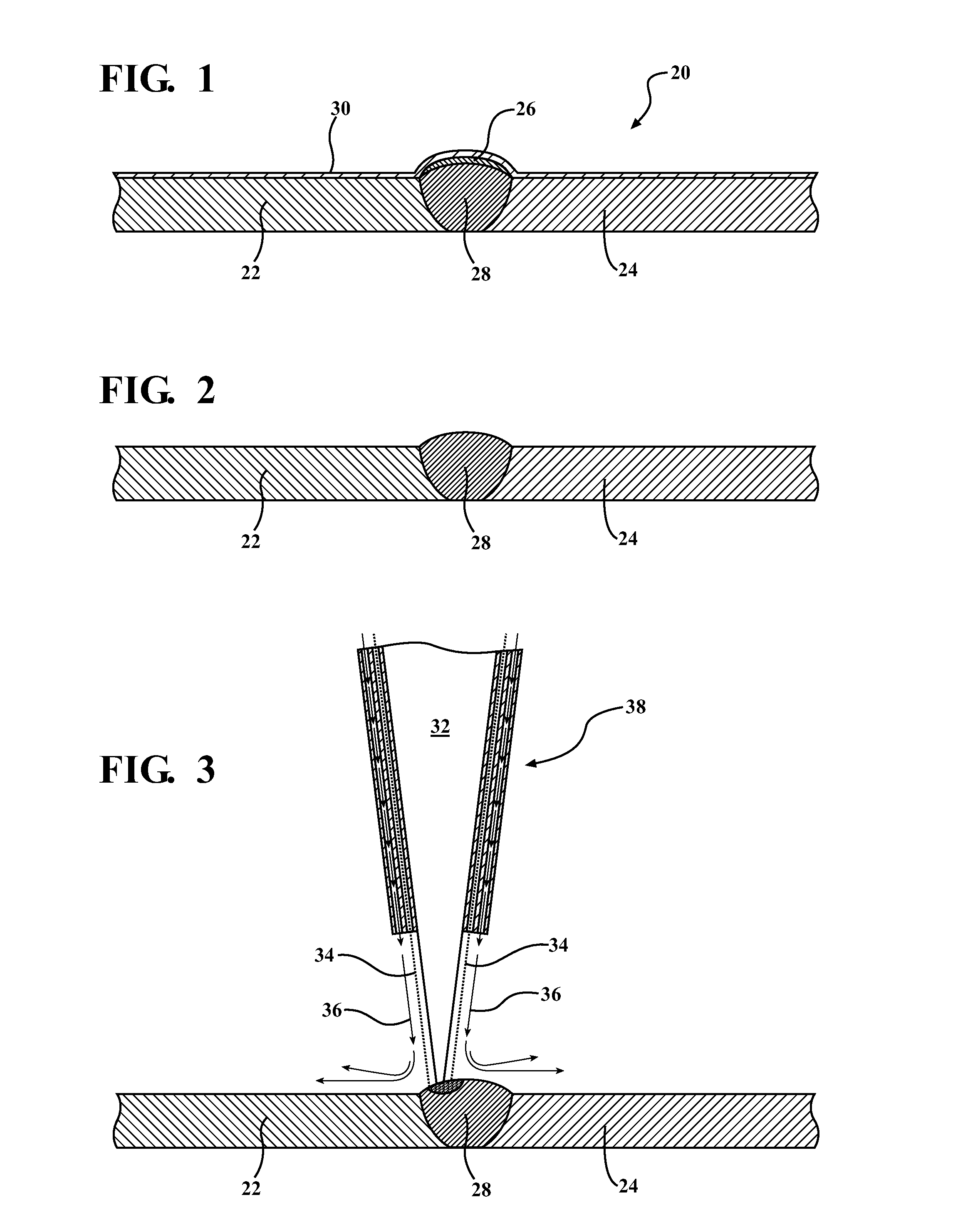

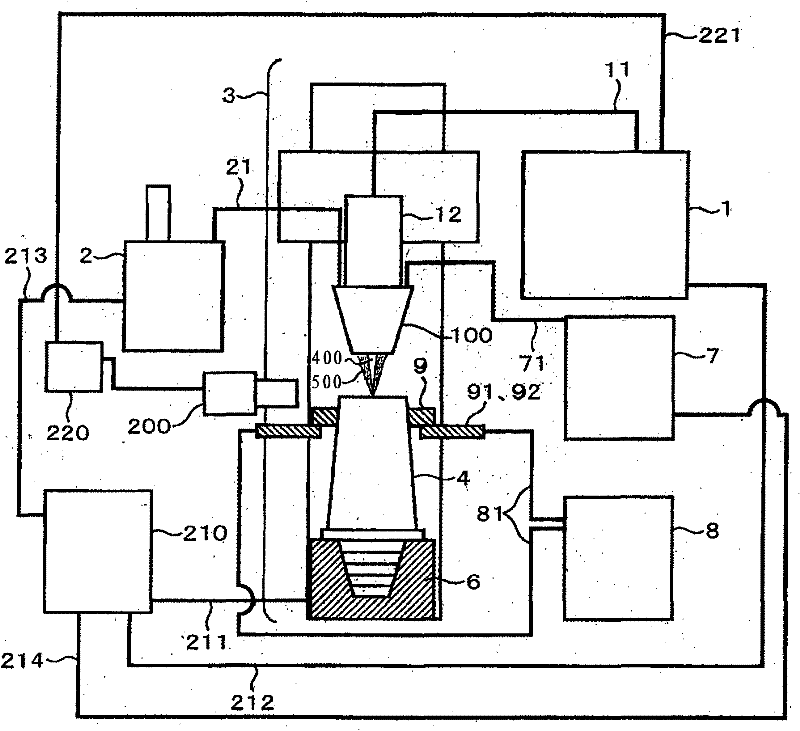

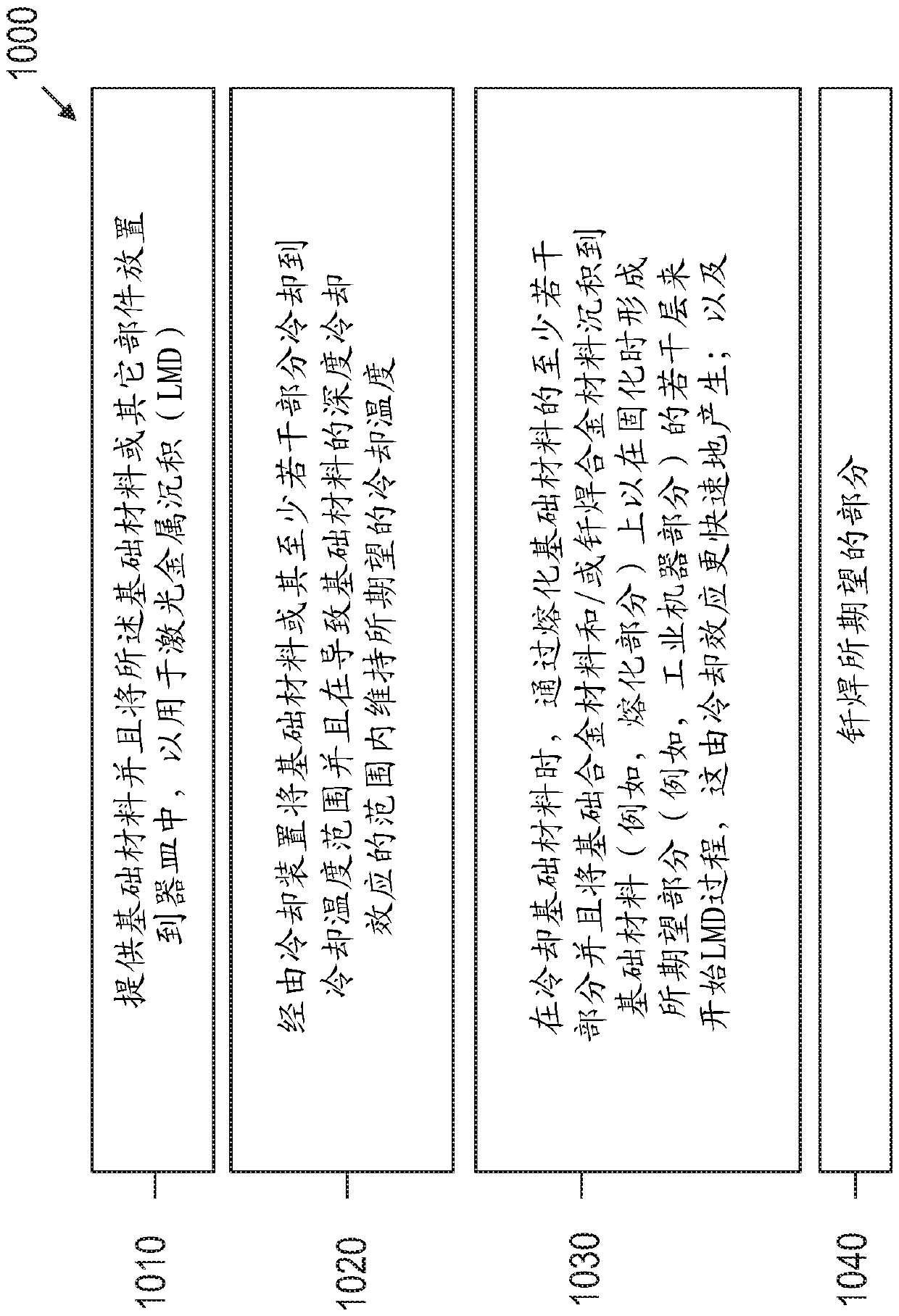

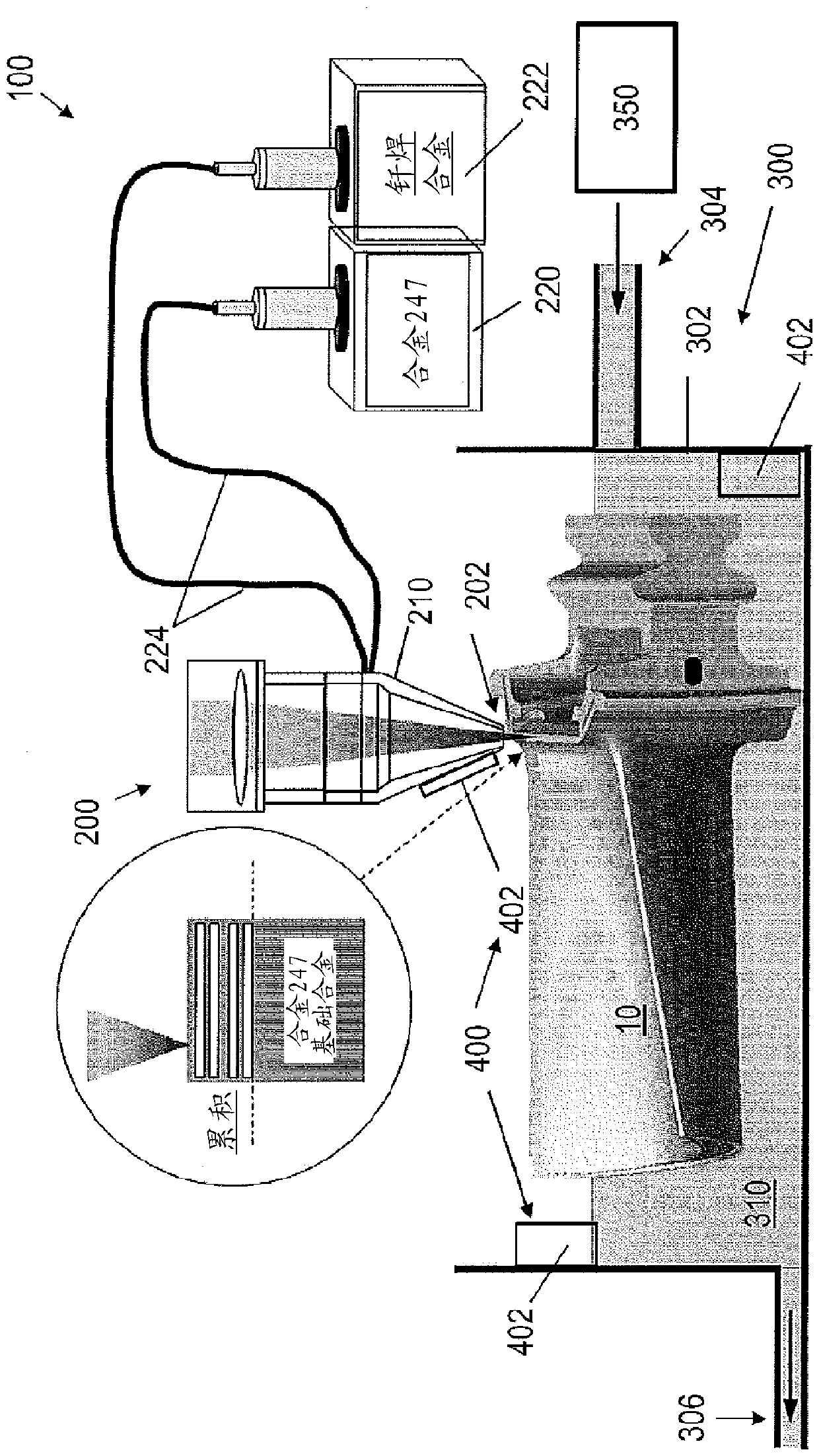

Laser metal deposition of high gamma prime superalloys with cooling effect

Systems (100) and methods (1000) for additively manufacturing or repairing a component from a base material (10). The system may include a laser metal deposition (LMD) system (200) operably connectedto a means for cooling (300) the base material during laser processing of additive materials deposited 5 in a melt pool on the base material. The LMD system includes a laser energy source (202) configured to direct laser energy towards the base material to form the melt pool thereon and to processes the deposited additive materials to form layers on the base material upon solidification. The meansfor cooling may be configured to cool the base material to within a cooling temperature range during the LMD 10 process, which results in, e.g., a cooling / freezing effect. This cooling effect shortens the solidification period during laser processing and allows for weld heat to be released from the base material.

Owner:SIEMENS ENERGY INC

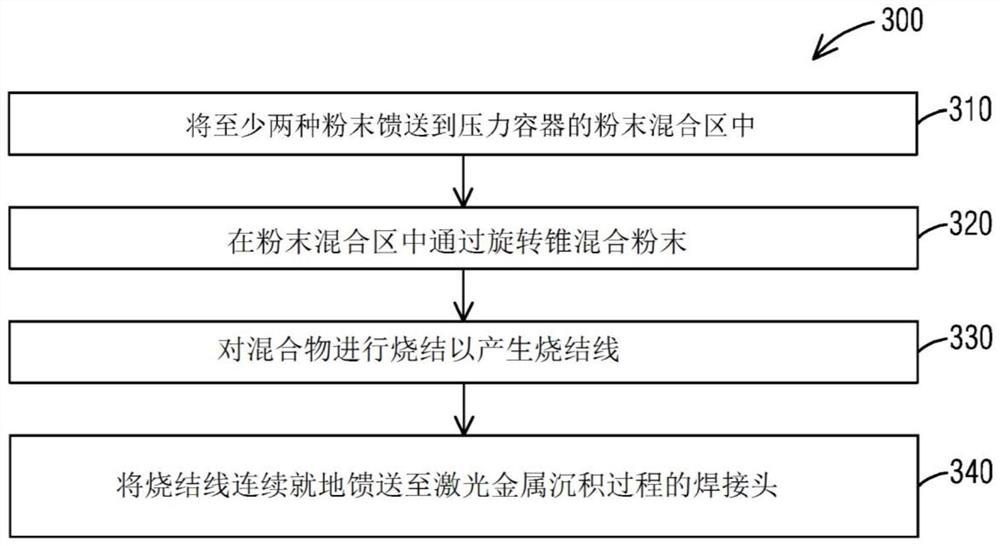

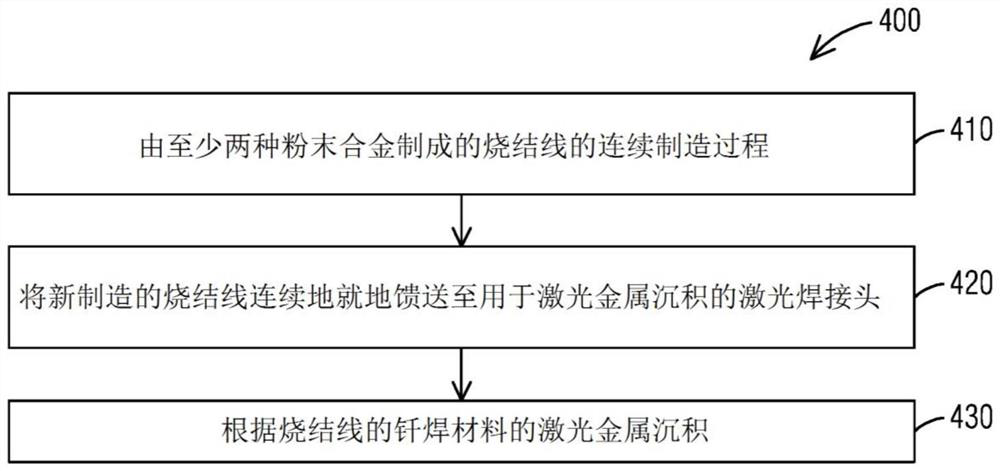

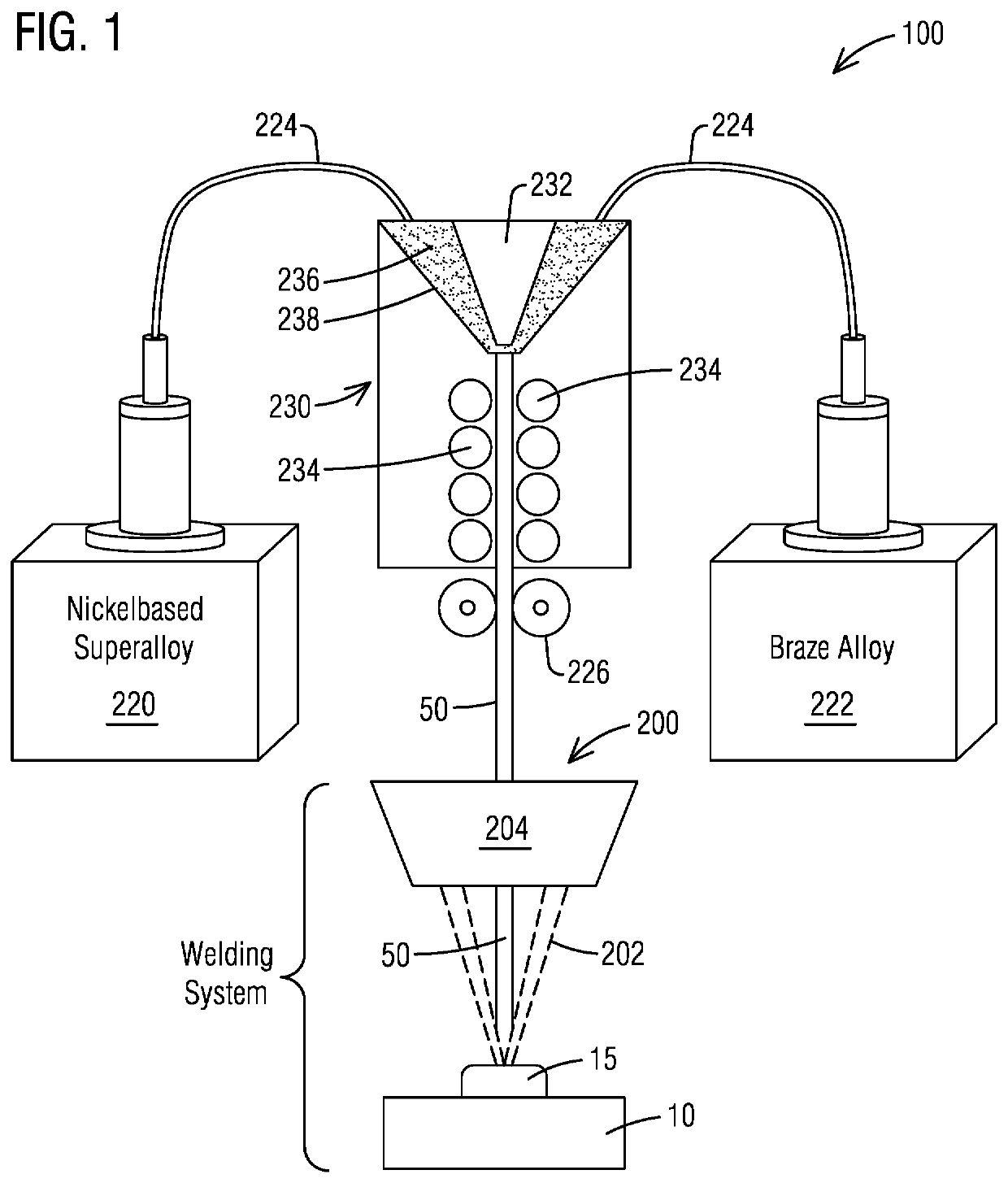

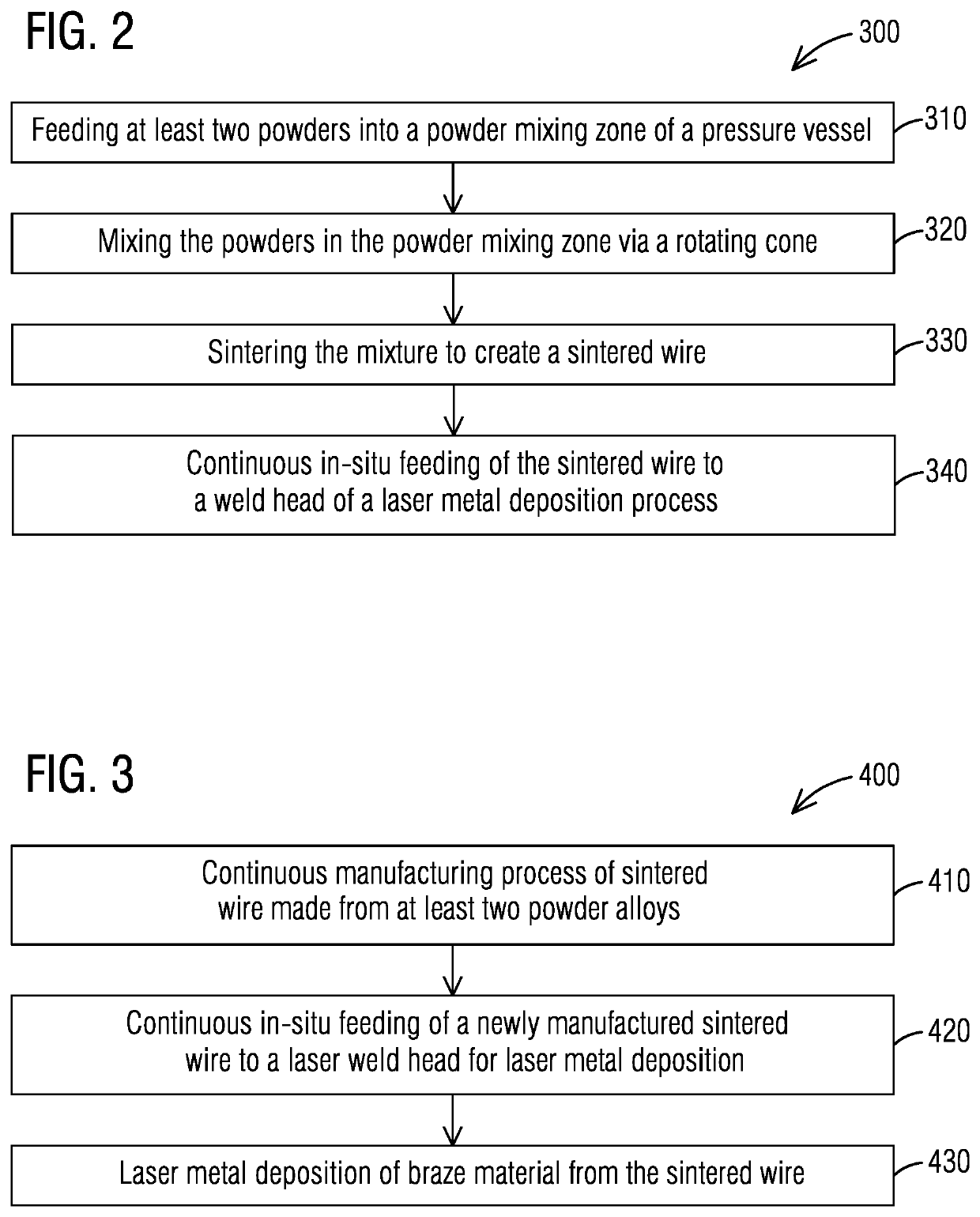

Method and system for additive manufacturing or repair with in-situ manufacturing and feeding of a sintered wire

A system for manufacturing of a sintered wire and in-situ feeding to a laser wire welding system is presented. The system includes a pressure vessel connected to a powder feed system for delivering atleast two powders to a powder mixing zone of the pressure vessel. The at least two powders are mixed via a rotating cone in the pressure vessel. After mixing, a heating device contained within the pressure vessel heats the mixture so that liquid phase sintering occurs and a sintered rod is created. The sintered wire is continuously fed to a laser metal deposition system for depositing a layer ofadditive material on a base material. A method of additively manufacturing or repairing a superalloy component is also presented.

Owner:SIEMENS ENERGY INC

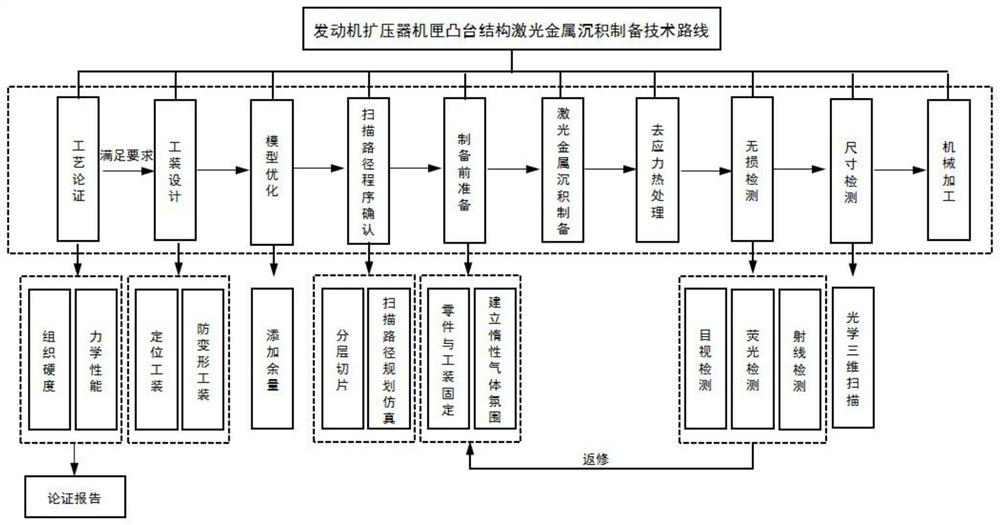

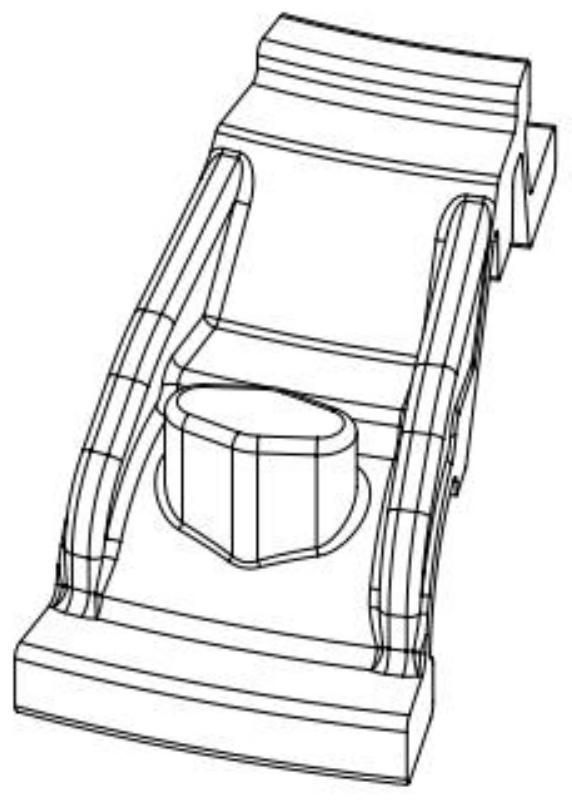

Laser metal deposition preparation method for boss structure of engine diffuser

PendingCN114734055AReduce accumulationPrevent oxidationAdditive manufacturing apparatusIncreasing energy efficiencyEngineering3d scanning

The invention discloses a laser metal deposition preparation method for a boss structure of an engine diffuser casing, which comprises the following steps of: outputting a process argument report through early-stage process verification; designing a positioning tool, and designing and manufacturing an anti-deformation follow-up tool; adding allowance to the size of the boss, and simulating the scanning path and reliability of the boss by software to obtain a scanning path program; before preparation, the parts, the shape follow-up tool and the positioning tool need to be assembled and installed, and the atmosphere of inert gas in the preparation process is created by adopting a flexible high-temperature-resistant film; carrying out boss laser metal deposition preparation according to the verified program, and after the temperature of the boss and the surface of the part is reduced, stopping filling the inert gas; putting the tool and the part into a vacuum heat treatment furnace; detecting the prepared boss, and if not, repairing the prepared boss; performing size comparison on the optical three-dimensional scanning model before and after the boss is prepared, wherein a result is a deviation measured value; and the prepared boss is machined. The invention provides a complete set of mature laser metal deposition preparation method for a boss structure of a case of an engine diffuser.

Owner:航发优材(镇江)增材制造有限公司

Methods of manufacturing axisymmetric body and axisymmetric product

InactiveUS10413999B2Wider widthAdditive manufacturing apparatusIncreasing energy efficiencyHeat-affected zoneEngineering

First, an annular first layer including a plurality of beads and having a width that is not less than twice a width of the bead is formed by laser metal deposition on a peripheral surface of a base metal, the peripheral surface facing outward or inward in a radial direction. Next, a plurality of annular height raising layers each including a plurality of beads are stacked on the first layer by the laser metal deposition. According to this configuration, an axisymmetric body including a flange portion having a relatively wide width can be manufactured while making a heat affected zone in the base metal extremely small.

Owner:KAWASAKI HEAVY IND LTD

Method and system for additive manufacturing or repair with in-situ manufacturing and feeding of a sintered wire

PendingUS20210069832A1TurbinesAdditive manufacturing apparatusSuperalloyAdditive layer manufacturing

A system for manufacturing of a sintered wire and in-situ feeding to a laser wire welding system is presented. The system includes a pressure vessel connected to a powder feed system for delivering at least two powders to a powder mixing zone of the pressure vessel. The at least two powders are mixed via a rotating cone in the pressure vessel. After mixing, a heating device contained within the pressure vessel heats the mixture so that liquid phase sintering occurs and a sintered rod is created. The sintered wire is continuously fed to a laser metal deposition system for depositing a layer of additive material on a base material. A method of additively manufacturing or repairing a superalloy component is also presented.

Owner:SIEMENS ENERGY INC

Laser metal deposition with inoculation

Systems and methods for additively manufacturing or repairing a component from a base material. The system may include an inoculation source to direct inoculation materials and a laser metal deposition (LMD) system to direct laser energy during laser processing of additive materials deposited in a melt pool on the base material. The LMD system includes a laser energy source configured to direct laser energy towards the base material and inoculation materials to form the melt pool thereon and to process the deposited additive materials and inoculation materials to form layers on the base material upon solidification.

Owner:SIEMENS ENERGY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com