Method for preparing CNTs (carbon nanotubes) reinforced high-entropy alloy laser deposition composite material

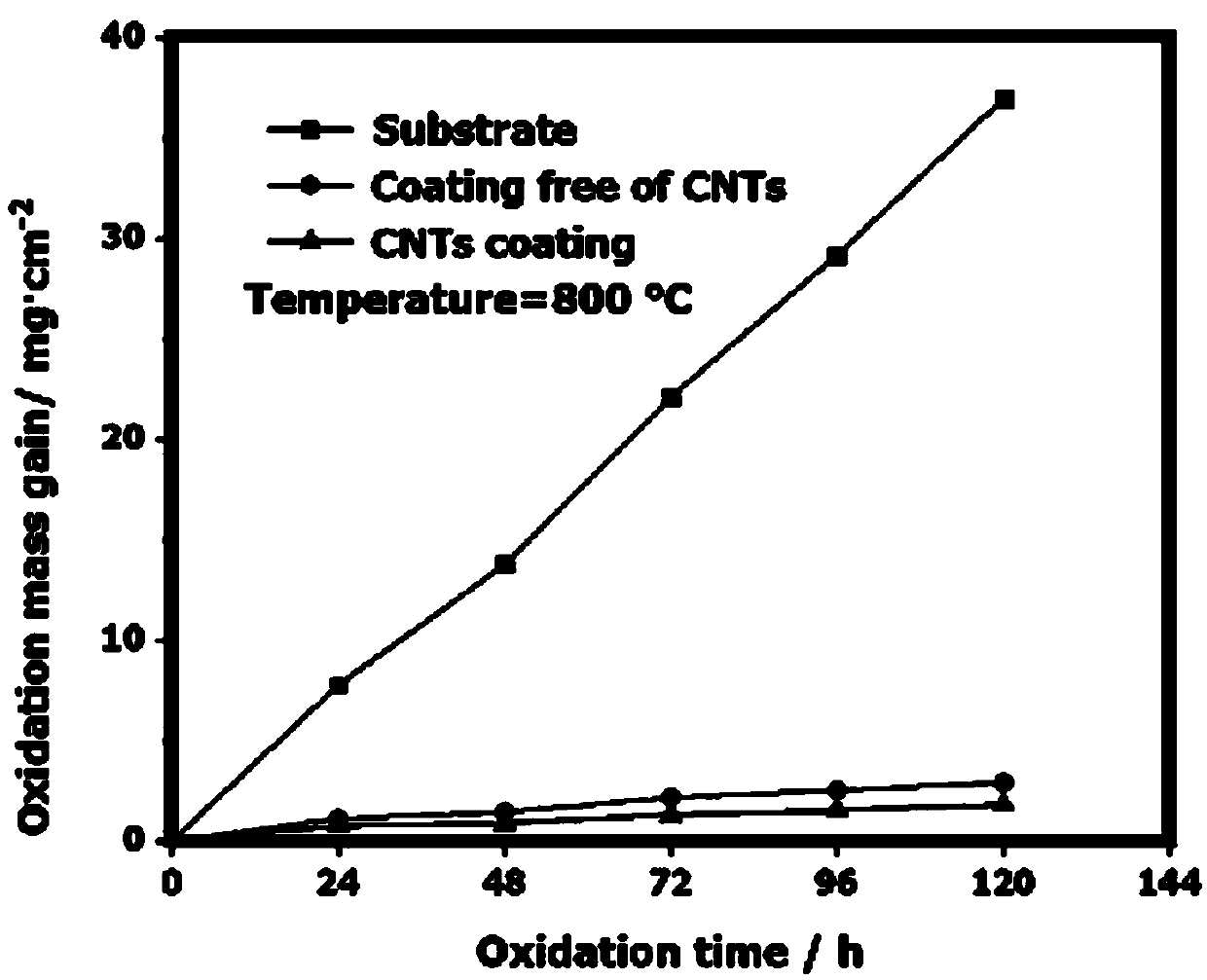

A technology of composite materials and high-entropy alloys, applied in metal material coating technology, additive processing, coating, etc., can solve the problems of poor high-temperature oxidation resistance and limit the application of titanium alloys, and achieve strong applicability, easy promotion and application, The effect of simple and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

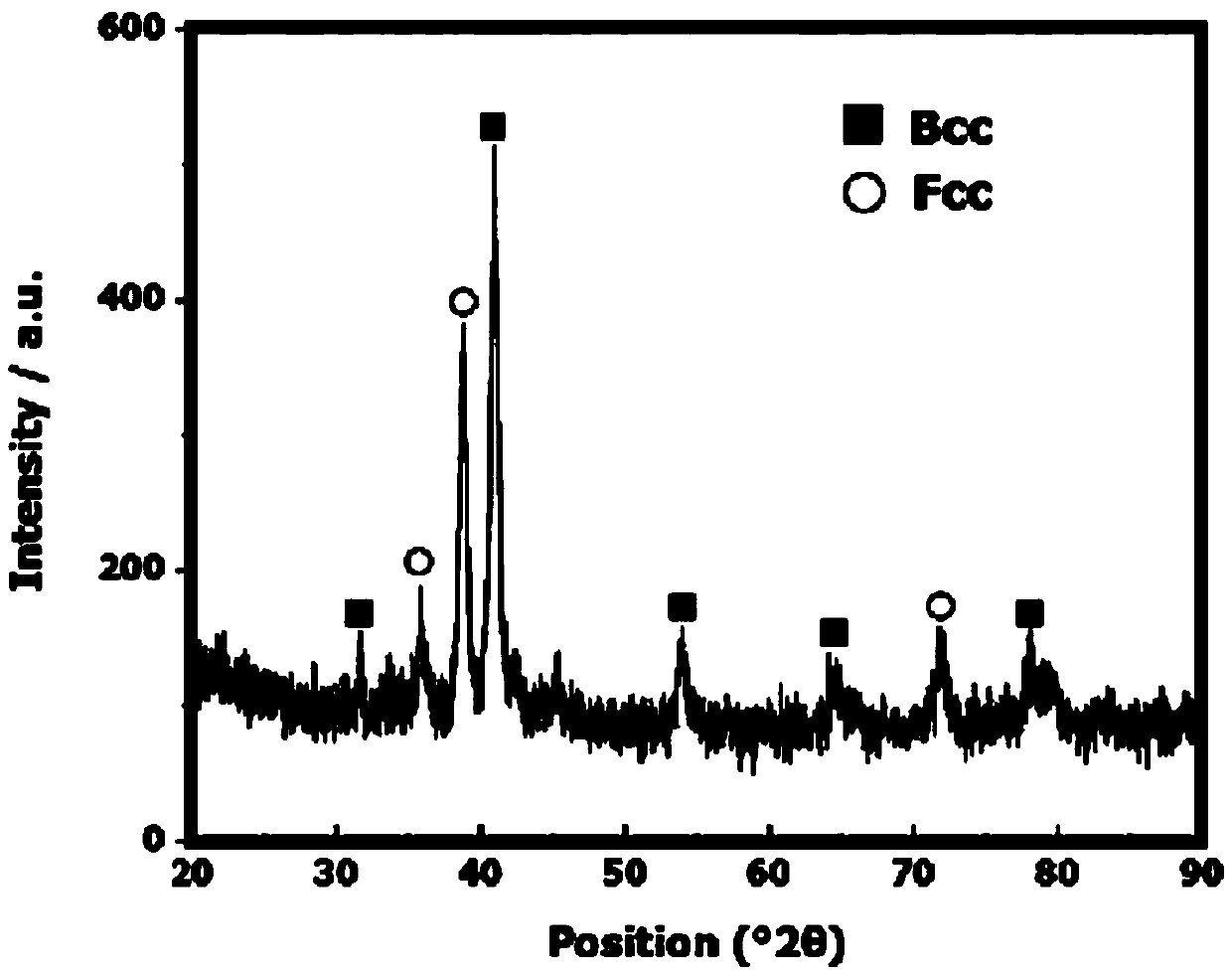

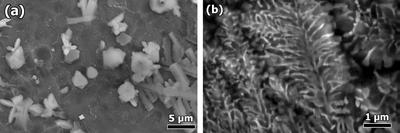

[0017] Cut the TA2 titanium alloy into a cuboid with a length of 10 mm, a width of 10 mm, and a thickness of 8 mm. Before the mixed powder deposition, the surface of the titanium alloy was cleaned, wiped and dried; the proportion (wt. %) was 87FeCoCrAlCu-10SiB 6 -3 (Ni / Ag-coated-CNTs) mixed powder LMD on the 10 mm × 10 mm surface of TA2 titanium alloy to form LMD coating.

[0018] Specific process steps:

[0019] 1) Before LMD, the surface of the TA2 titanium alloy to be treated is smoothed with 120-grit sandpaper to make it

[0020] The roughness of the surface to be treated reaches Ra 2.5 μm; then the surface is cleaned with 25% sulfuric acid aqueous solution by volume, and the pickling time is 5 to 10 minutes; after that, rinse with clean water, wipe clean the surface of the workpiece to be melted with alcohol, and dry it;

[0021] 2) Weigh 87 g of FeCoCrAlCu powder, SiB 6 Powder 10 g, single wall (Ni / Ag

[0022] Coating-CNTs) powder 3 g, put into a beaker, in which FeCo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com