Basal plate preheating system formed by laser metal deposition

A substrate and metal technology, applied in the field of substrate preheating system of laser metal deposition forming, to achieve the effect of high control precision, fast reflection speed and uniform temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

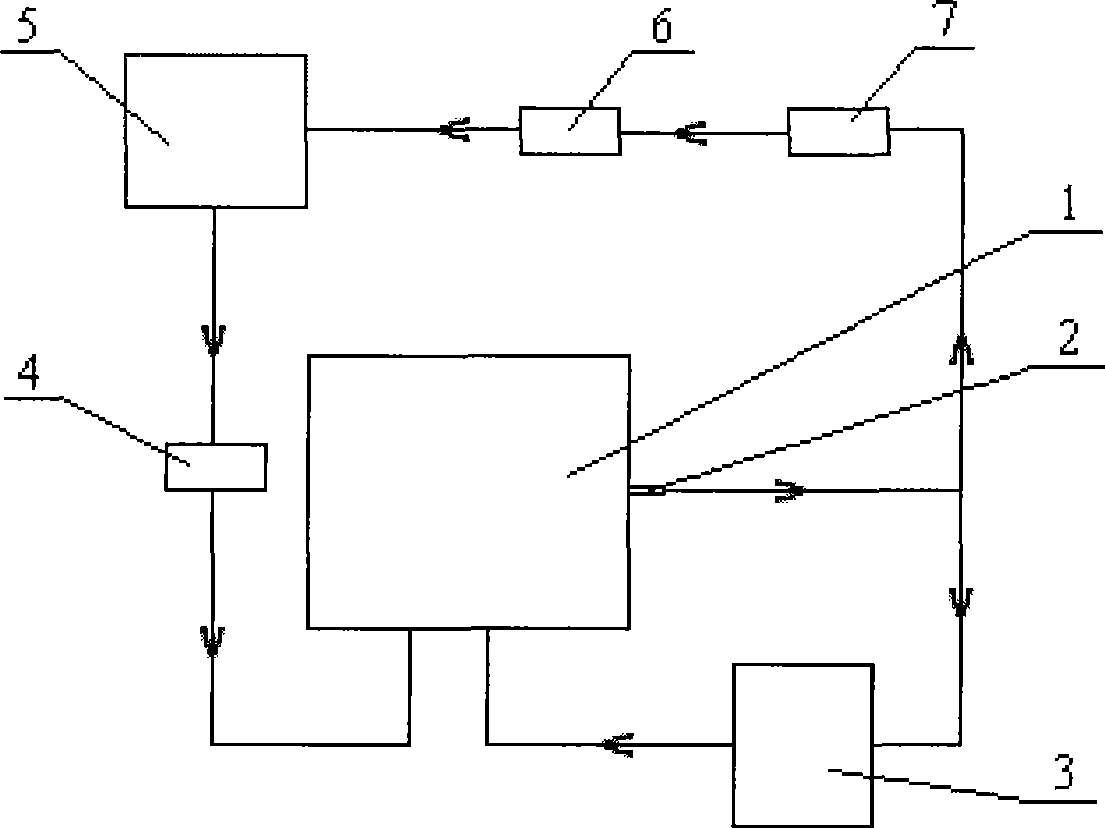

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

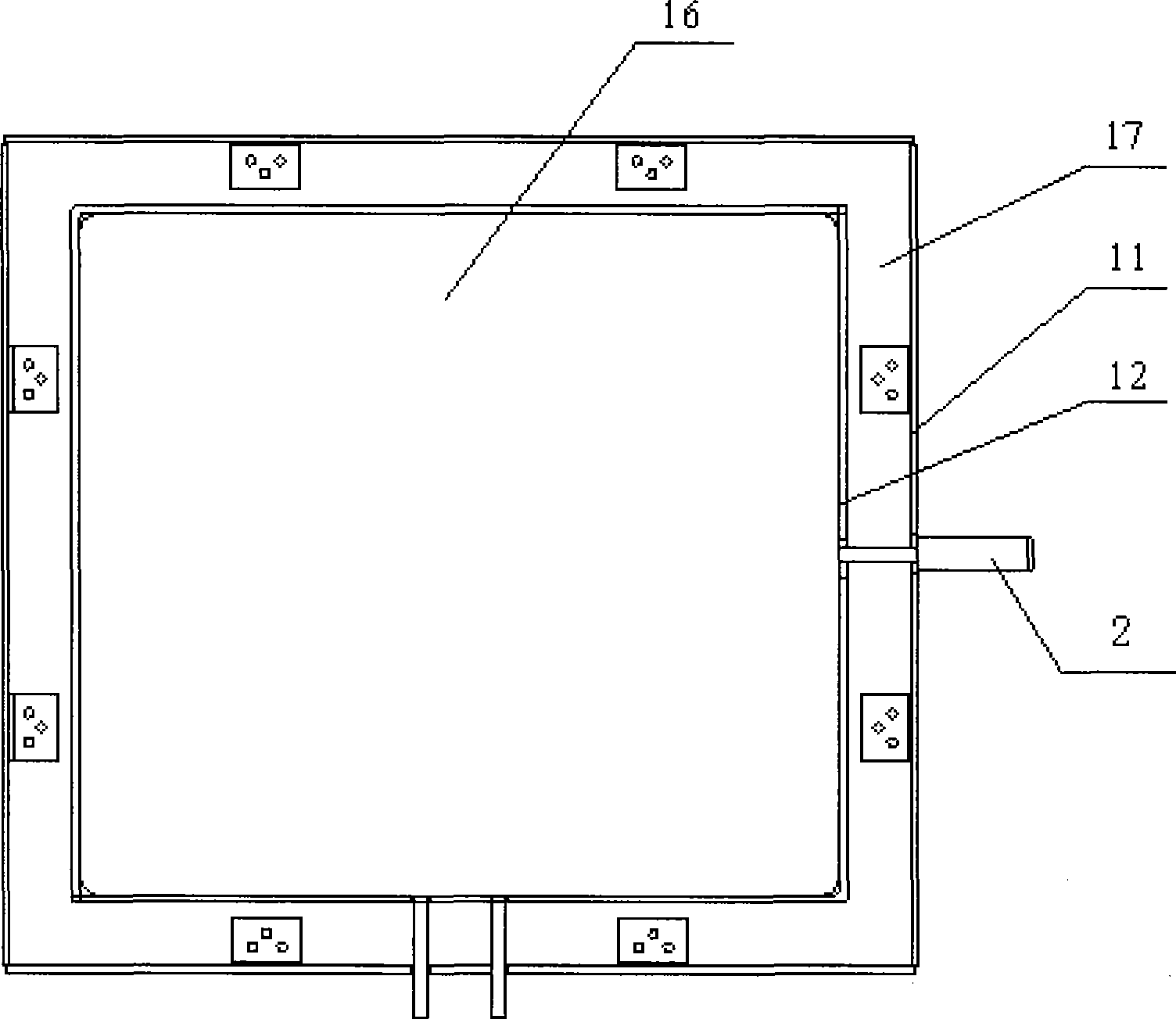

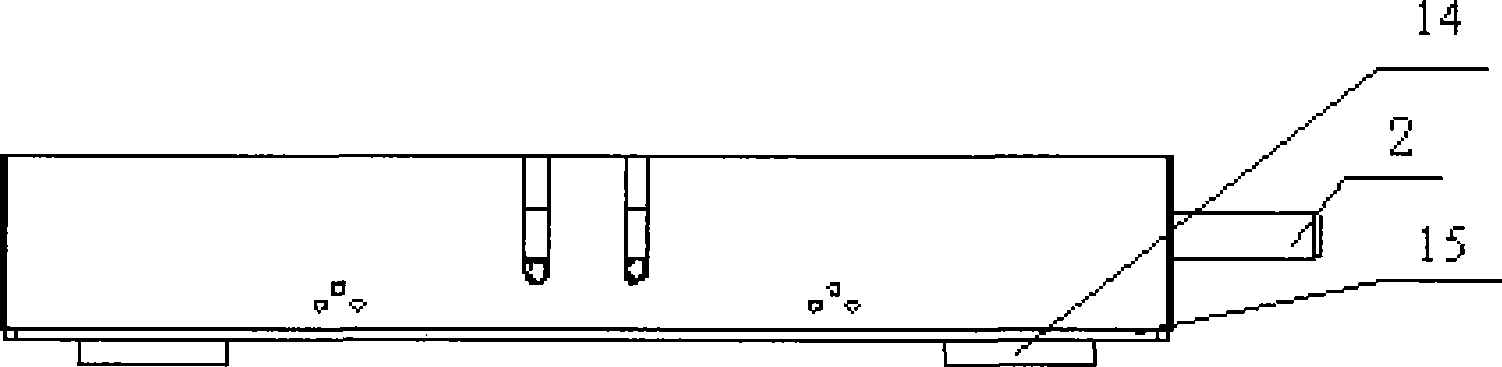

[0016] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0017] Such as Figure 2A , 2B and image 3 As shown, the working environment of the substrate preheater 1 is high temperature and dusty, and at the same time it is required to heat up rapidly and maintain a constant temperature. Therefore, the system of the present invention adopts the following structure: comprising a substrate preheater 7 and its temperature control device, wherein The substrate preheater 7 is a box structure with a base plate 15, an inner wall 12 and an outer wall 11 arranged around the base plate 15, an insulating material 17 is arranged between the inner wall 12 and the outer wall 11, and the base plate 15 is installed through a heat insulating material 18. There is an electric heating tube 20, and a copper plate 16 is installed in the casing and above the electric heating tube 20, and the terminal of the electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com