Axially symmetric body, and axially symmetric body manufacturing method

一种轴对称体、制造方法的技术,应用在制造工具、附加制造、工艺效率的提高等方向,能够解决浪费材料、金属模具大笔费用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

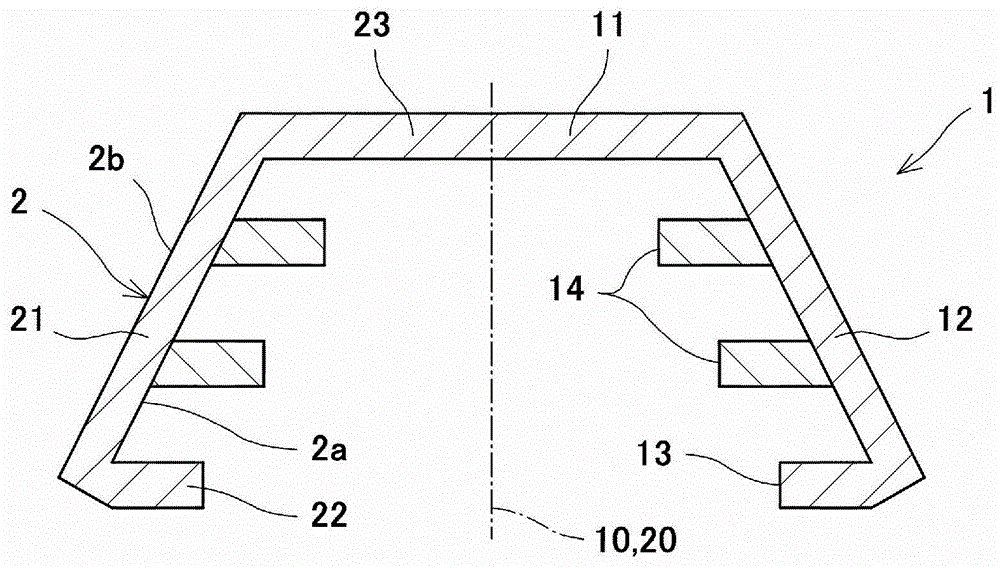

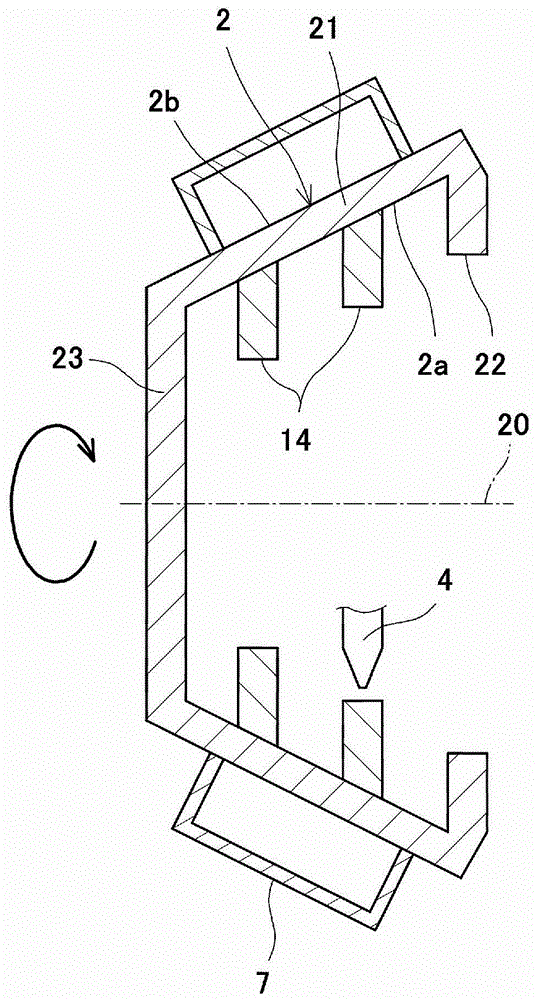

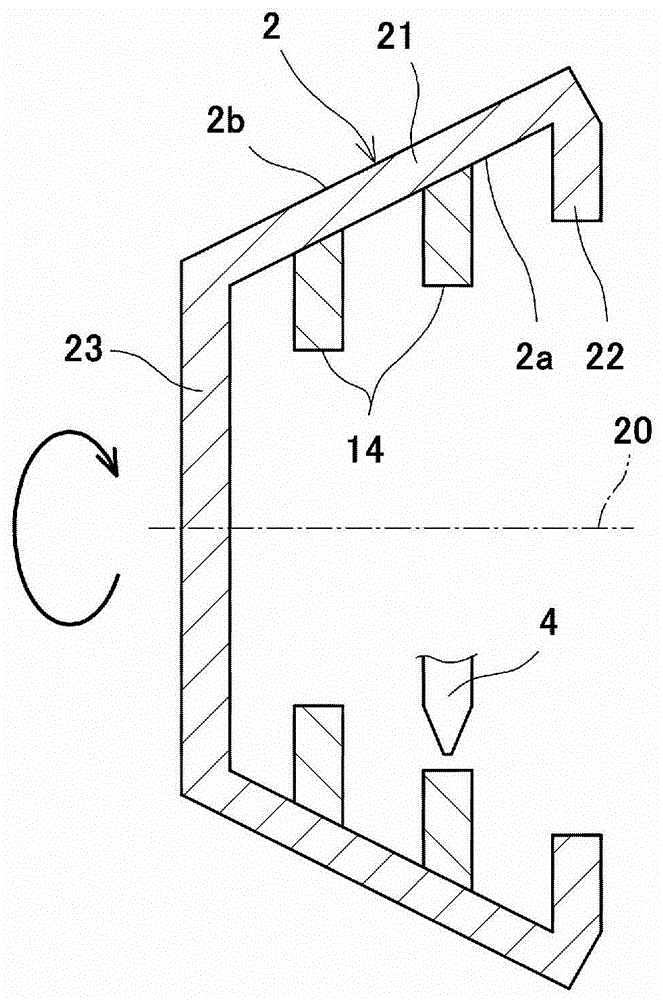

[0031] A method for manufacturing an axisymmetric body according to an embodiment of the present invention is used for manufacturing figure 1 An axisymmetric body 1 having a shape symmetrical about a central axis 10 as shown. In this embodiment, the axisymmetric body 1 is formed in the axial direction ( figure 1 The middle is downward) the hollow of the upper opening. Specifically, the axisymmetric body 1 includes: a top wall 11, a tapered peripheral wall 12 extending from the peripheral portion of the top wall 11, and two first flange portions 14 protruding radially inward from the middle part of the peripheral wall 12 (equivalent to The flange portion in the present invention), and the second flange portion 13 protruding radially inward from the tip end of the peripheral wall 12 .

[0032] However, the shape of the axisymmetric body 1 is not limited to figure 1 the shape shown. For example, the peripheral wall 12 of the axisymmetric body 1 can also be straight. Moreover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com