Online detecting and eliminating device and method for melt channel material defects in laser metal forming

A metal forming and detection device technology, which is applied in the direction of measuring devices, optical testing flaws/defects, and analyzing materials, can solve the problems of targeted elimination, inability to scan online detection of small material defects, melt channel forming, etc., and achieve easy realization and elimination Effect of internal material defects, reducing the risk of fatigue fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

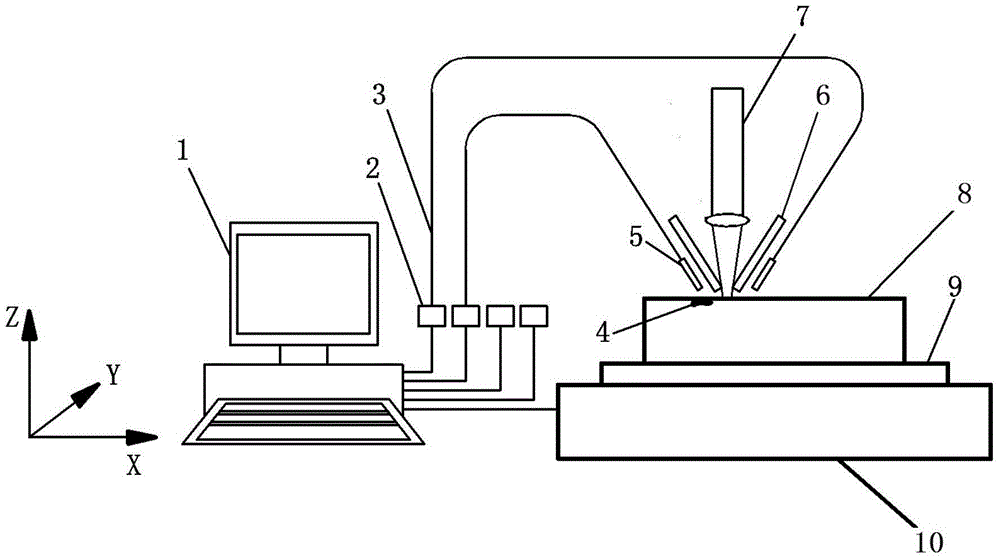

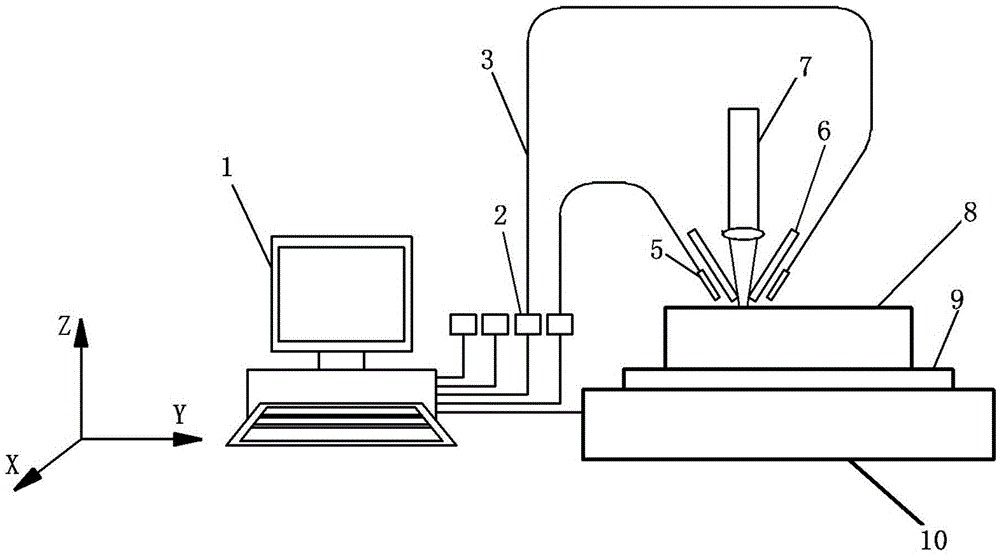

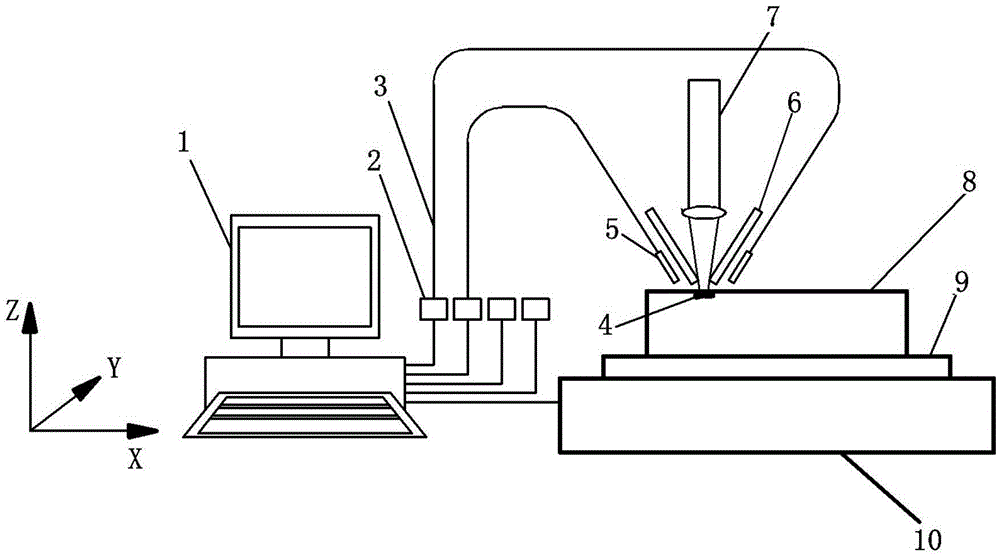

[0036] A TA15 titanium alloy cuboid part with a length, width and height of 150×50×60 mm is fabricated by laser deposition forming, and the titanium alloy part 8 is located above the substrate 9 and the workbench 10 . The (x, y) coordinate orientation of the lower left corner of part 8 in the forming plane is (0mm, 0mm). The forming process parameters adopted are: laser power 300W, scanning speed V 10mm / s, powder feeding rate 4.9g / min, laser spot diameter d 0.5mm, layer thickness 0.1mm, overlapping rate 40%, scanning method For reciprocating scanning. When making the part, the device and method of the present invention are used to realize the online detection and elimination of material defects of the melting channel in laser deposition forming.

[0037] The fiber-optic two-color thermometer 2 used in this example has a response time of 2ms, the temperature probe 5 can withstand a high temperature of 250°C, the temperature measurement range is 350-1300°C, the temperature meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com