Complicated thin-walled workpiece formation system and method based on progressive formation and additive manufacturing

A technology of additive manufacturing and incremental forming, applied in the direction of additive manufacturing, additive processing, process efficiency improvement, etc., to achieve efficient manufacturing and achieve the effect of sustainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

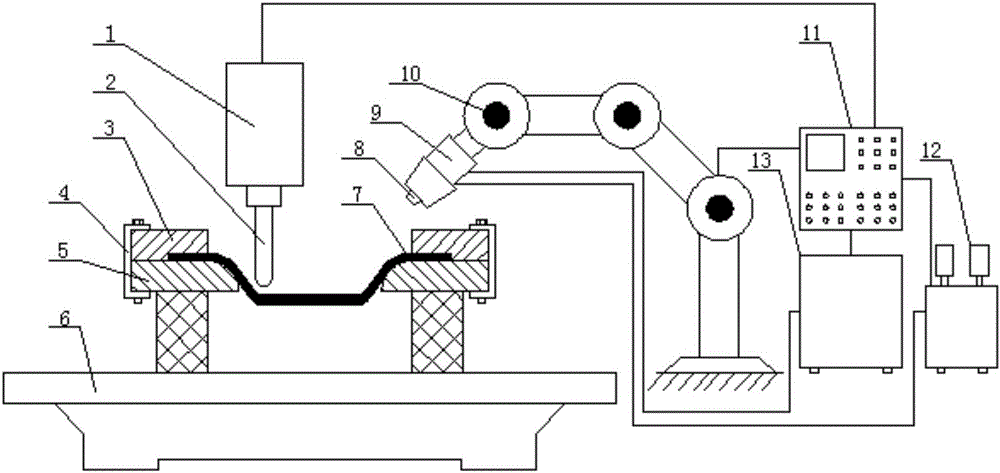

[0023] The composite forming system of metal components based on incremental forming and additive manufacturing of the present invention, such as figure 1 As shown, it includes an incremental forming system, a laser metal deposition system, and a control system 11, and the control system 11 can adopt a programmable controller.

[0024] The progressive forming system includes a workbench 6, a three-dimensional mobile platform and an electric spindle 1. The three-dimensional mobile platform can be installed on the workbench 6, or can be separated from the workbench 6. The electric spindle 1 is installed on the three-dimensional mobile platform (not shown in the figure), the electric spindle 1 and the three-dimensional mobile platform are connected with the control system 11, and the control system 11 controls the three-dimensional mobile platform to drive the electric spindle 1 in the X, Y, and Z directions To achieve three-dimensional translation and rotation, the control syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com