Green preparation method of light high-strength cordierite porous ceramic and filter

A technology of porous ceramics and cordierite, which is applied to the green preparation method of light-weight high-strength cordierite porous ceramics and the field of filters, can solve the problems of cracking of micro-cracked products, unfavorable environmental protection, many kinds of additives, etc. Improve compressive strength and thermal shock resistance, and reduce drying shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

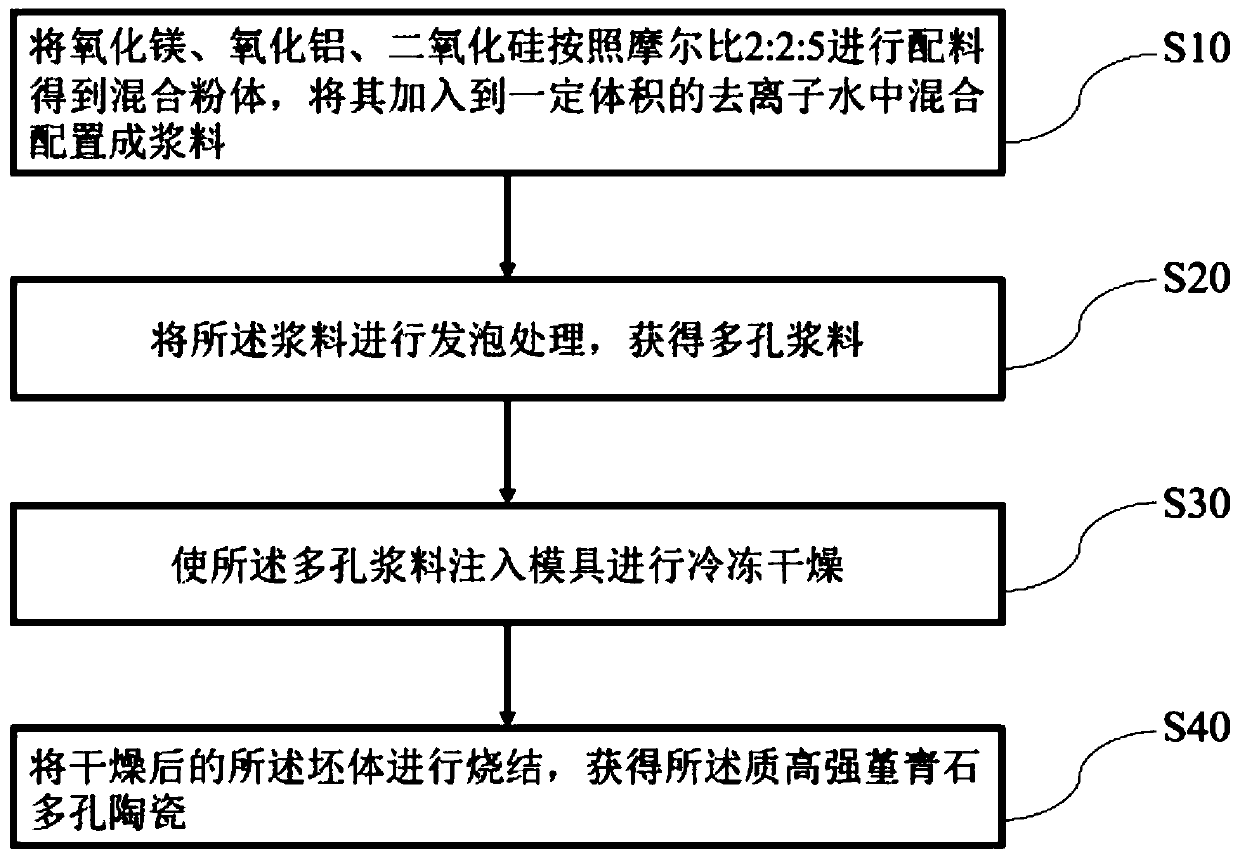

[0044] The green preparation method of the lightweight high-strength cordierite porous ceramic material according to the embodiment of the present invention, such as figure 1 shown, including the following steps:

[0045] Step S10, mixing magnesium oxide, aluminum oxide, and silicon dioxide according to the stoichiometric ratio of cordierite to obtain a mixed powder, adding it to a certain volume of deionized water and mixing it to form a slurry;

[0046] Step S20, subjecting the slurry to foaming treatment to obtain foam slurry;

[0047] Step S30, injecting the foam slurry into a mold for freeze-drying;

[0048] Step S40, sintering the dried green body to obtain the lightweight high-strength cordierite porous ceramic.

[0049] In other words, according to some specific embodiments of the present invention, magnesium oxide, aluminum oxide, and silicon dioxide are used as raw materials to prepare light-weight and high-strength cordierite porous ceramic materials. The mixed p...

Embodiment 1

[0074] It is configured into a slurry of 15vol.%, the total volume of the slurry is 200ml, and gelatin accounting for 8wt% of the total mass of raw material powder is adopted. Magnesium oxide (purity 99.9%) with a particle size of 50nm, aluminum oxide (purity 99.99%) with a particle size of 300nm, and silicon dioxide (purity 99.4%) with a particle size of 10 μm, according to the cordierite stoichiometric ratio (Mg 2 Al 4 Si 5 o 18 ) for batching, then add 2wt% dispersant (ammonium polyacrylate) and 140ml deionized water of the total mass of the raw material powder, and ball mill and mix the mixture for 17h on a roller ball mill (rotating speed is 100rpm). Heat and dissolve the gelatin with 30ml of deionized water, then stir the previously mixed slurry and gelatin solution at a low speed of 450rpm to make it evenly mixed; then add 2g / L of foaming agent (sodium lauryl sulfate) to carry out For foaming, gradually increase the speed and stabilize it to 1200rpm. After stirring f...

Embodiment 2

[0077] It is configured into a 20vol.% slurry, the total volume of the slurry is 200ml, and gelatin accounting for 8wt% of the total mass of the raw material powder is used. Magnesium oxide (purity 99.9%) with a particle size of 50nm, aluminum oxide (purity 99.99%) with a particle size of 300-500nm, and silicon dioxide (purity 99.4%) with a particle size of 10 μm, according to the cordierite stoichiometric ratio (Mg 2 Al 4 Si 5 o 18 ) for batching, then add 4wt% dispersant (ammonium polyacrylate) and 130ml deionized water of the total mass of raw material powder, and ball mill and mix the mixture for 17h on a roller ball mill (rotating speed is 100rpm). Heat and dissolve the gelatin with 30ml of deionized water, then stir the previously mixed slurry and gelatin solution at a low speed of 450rpm to make it evenly mixed; then add 2g / L of foaming agent (sodium lauryl sulfate) to carry out For foaming, gradually increase the speed and stabilize it to 1200rpm. After stirring for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com