Method in use for conticaster for controlling solidification structure of casting block

A continuous casting machine and casting billet technology, applied in the field of continuous casting steel production in the metallurgical industry, can solve the problems of difficult to solve problems such as central shrinkage and central porosity of the casting billet, large equipment investment, composition segregation, etc., to achieve grain refinement, Low operating cost and the effect of eliminating subcutaneous air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

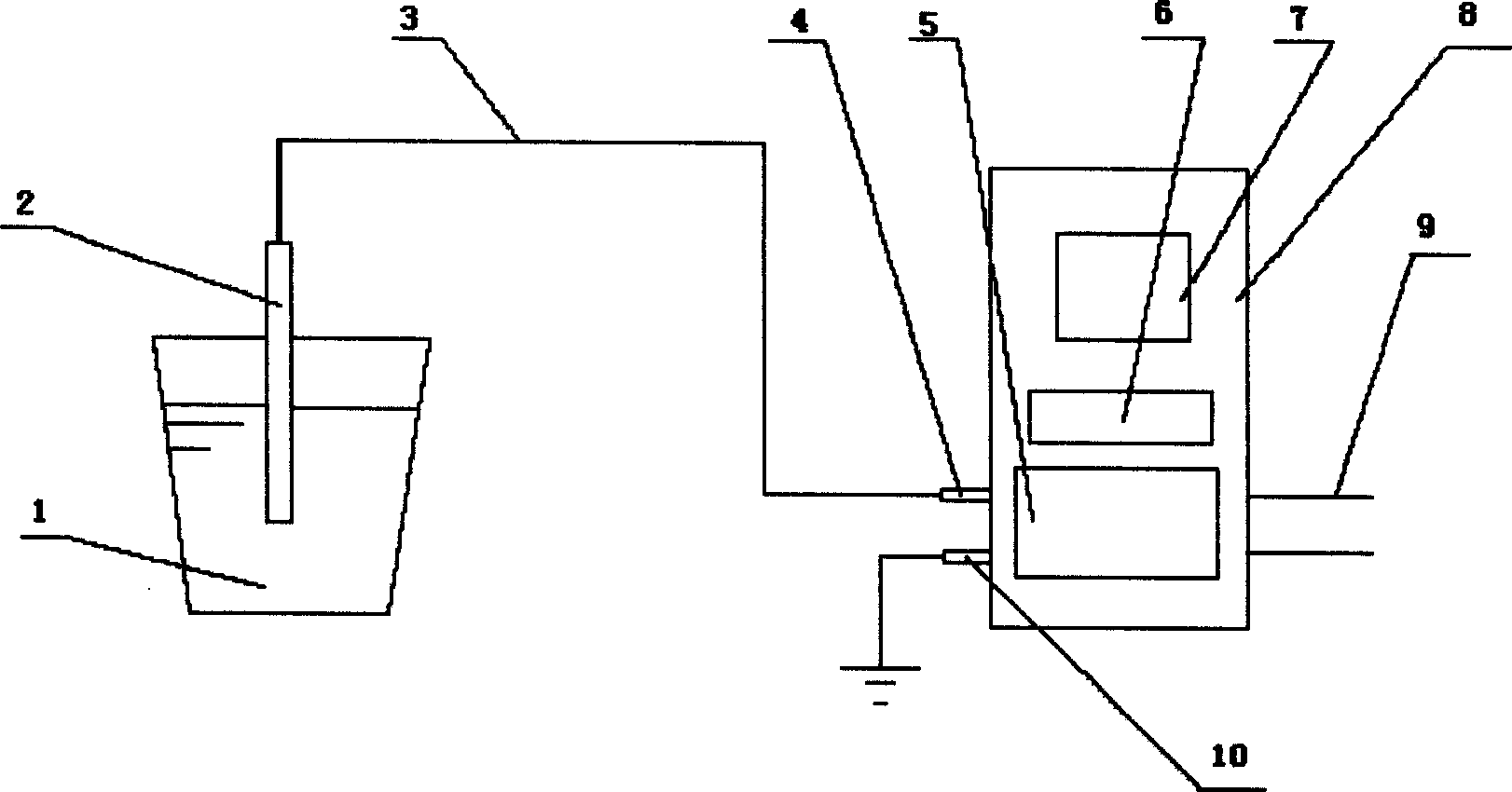

Embodiment 1

[0016] When the 5-strand billet continuous casting machine in a steel plant was casting normally, before the test, a 500mm continuous casting billet was taken from the flame cutting place of the first-class billet for low-magnification comparative analysis. Then insert a cermet electrode with a diameter of 10mm into the first-class 150×150mm crystallizer of the casting machine, and the depth of the electrode inserted into the molten steel is 100mm; the positive pole of the high-frequency pulse power supply is connected to the raceway bearing sleeve of the tension leveler with a cable (grounded). An 8V high-frequency pulse electric field is passed through the two electrodes, and the high-frequency pulse current value is 180A. The casting speed of the continuous casting machine is 2.1m / min, the casting steel is low-alloy steel, and the pouring temperature of the tundish is 1520°C. After 30 minutes, at the first-class flame cutting place, a 500mm continuous casting slab was taken...

Embodiment 2

[0018] When the six-strand billet continuous casting machine in a steel plant is in normal production, before the high-frequency pulse electric field treatment, a 500mm continuous casting billet is taken from the flame cutting place of the first-class billet for low-magnification comparative analysis. Then insert an aluminum carbon electrode with a diameter of 100mm and a length of 1500mm into the tundish of the casting machine. The depth of the electrode inserted into the molten steel is 700mm; the positive pole of the high-frequency pulse power supply is connected to the foundation of the continuous casting machine with a cable (grounded). A 12V high-frequency pulse electric field is passed through the two electrodes, and the high-frequency pulse current value is 480A. The casting speed of the continuous casting machine is 2.2m / min, the casting steel type is 20MnSi, and the tundish pouring temperature is 1530°C. After 30 minutes, at the first-class flame cutting place, a 500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com