Improved production technology for fine dried noodles

A production process and noodle technology, which is applied in food drying, food science, etc., can solve the problems affecting the quality of dried noodles and prone to breakage, and achieve the effects of reducing internal cracks and voids, improving flexural resistance, and reducing fracture rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of improved vermicelli production technology, comprises the following steps:

[0025] A, kneading dough; choose the wheat flour of gluten content 33%, protein content 19% to knead dough, the mixing ratio of wheat flour and water is 2:1;

[0026] B, ripening; the dough is allowed to stand in an environment where the temperature is 40°C and the humidity is 70% and ripened for 3 hours;

[0027] C, sheeting; put the matured dough into a noodle press, and press it into a dough sheet with a thickness of 1mm;

[0028] D. Pre-drying; put the noodles into the drying room, control the drying temperature at 45°C, and dry for 10 minutes;

[0029] E, cutting into strips; cutting the pre-dried noodles into strips;

[0030] F, dry; Noodles are dried;

[0031] G, cut off; cut off the dried noodles to a set length;

[0032] H, packaging: weighing and packaging the cut dried noodles.

[0033] In this embodiment, by pre-drying the dough sheet, the uniformity of the water conte...

Embodiment 2

[0035] A kind of improved vermicelli production technology, comprises the following steps:

[0036] A, kneading dough; choose the wheat flour of gluten content 33%, protein content 19% to knead dough, the mixing ratio of wheat flour and water is 2:1;

[0037] B, ripening; the dough is allowed to stand in an environment where the temperature is 40°C and the humidity is 70% and ripened for 3 hours;

[0038] C, sheeting; put the matured dough into a noodle press, and press it into a dough sheet with a thickness of 1mm;

[0039] D. Pre-drying; put the noodles into the drying room, control the drying temperature at 45°C, and dry for 10 minutes;

[0040] E, cutting into strips; cutting the pre-dried noodles into strips;

[0041] F, dry; Noodles are dried;

[0042] G, cut off; cut off the dried noodles to a set length;

[0043] H, packaging: weighing and packaging the cut dried noodles.

[0044] In step F, drying comprises the following steps,

[0045] F1. The temperature of th...

Embodiment 3

[0052] A kind of improved vermicelli production technology, comprises the following steps:

[0053] A, kneading dough; choose the wheat flour of gluten content 33%, protein content 19% to knead dough, the mixing ratio of wheat flour and water is 2:1;

[0054] B, ripening; the dough is allowed to stand in an environment where the temperature is 40°C and the humidity is 70% and ripened for 3 hours;

[0055] C, sheeting; put the matured dough into a noodle press, and press it into a dough sheet with a thickness of 1mm;

[0056] D. Pre-drying; put the noodles into the drying room, control the drying temperature at 45°C, and dry for 10 minutes;

[0057] E, cutting into strips; cutting the pre-dried noodles into strips;

[0058] F, dry; Noodles are dried;

[0059] G, cut off; cut off the dried noodles to a set length;

[0060] H, packaging: weighing and packaging the cut dried noodles.

[0061] In step F, drying comprises the following steps,

[0062] F1. The temperature of th...

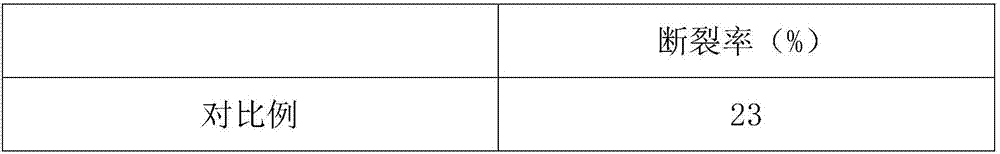

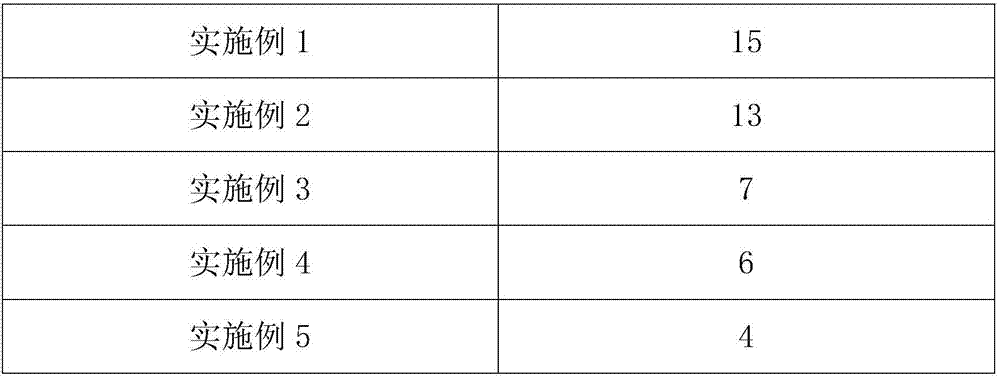

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com