Ingot tilting fixture for turning over polycrystalline silicon ingot

A technology of polycrystalline silicon ingots and fixtures, which is applied in the manufacture of tools, work accessories, stone processing equipment, etc., and can solve problems such as difficulty, unimaginable consequences, and heavy weight of silicon ingots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

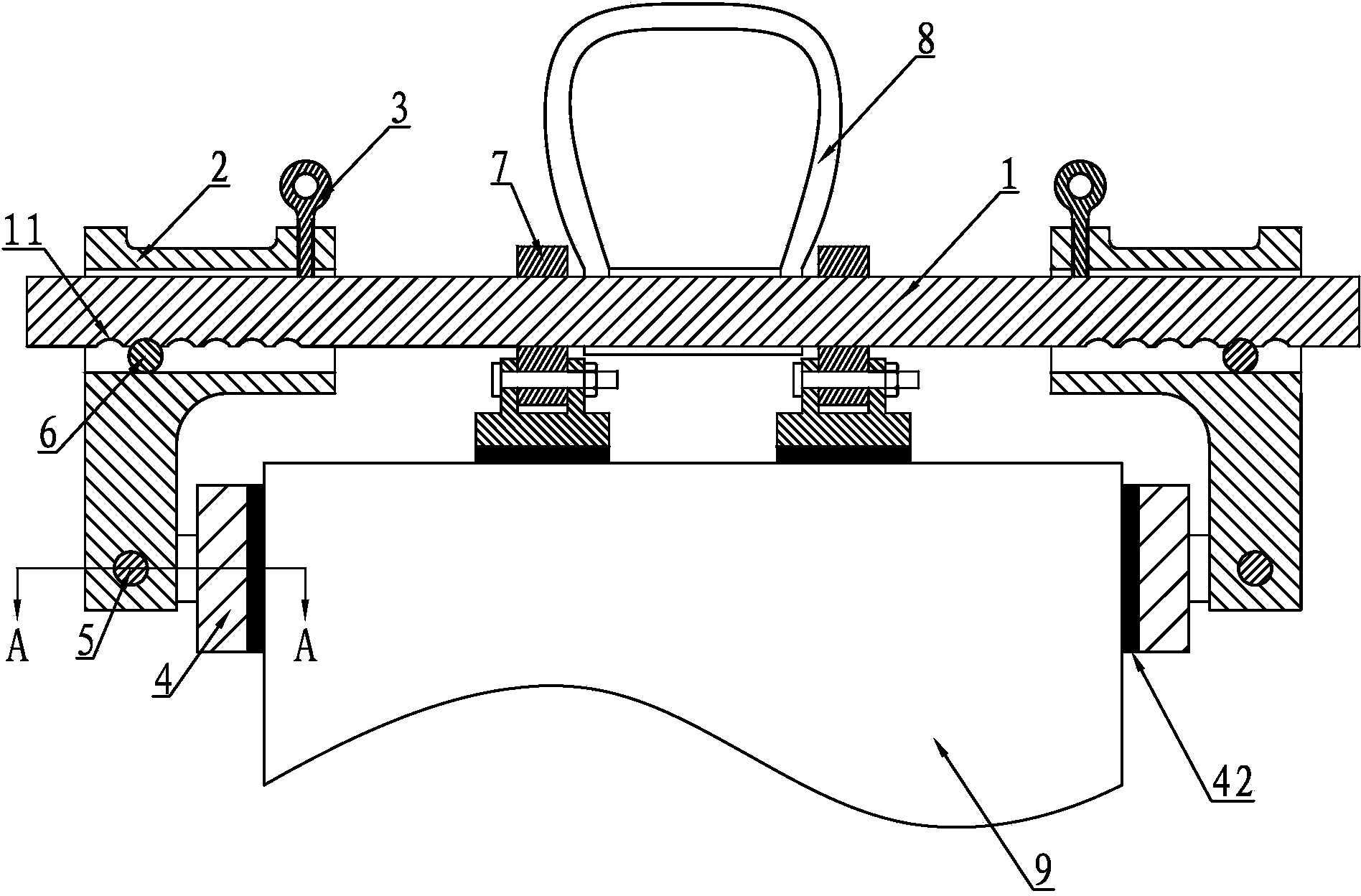

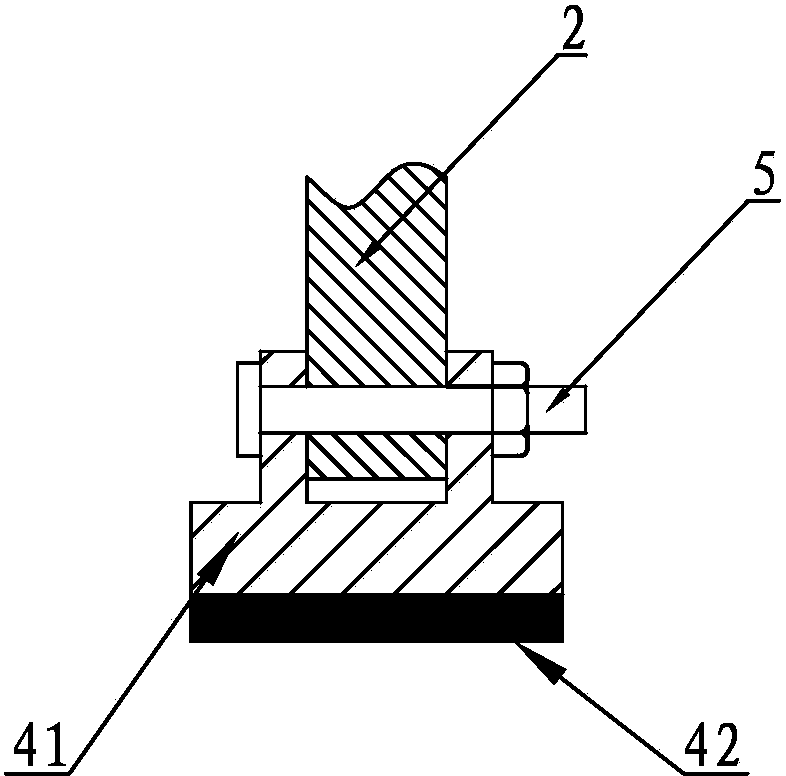

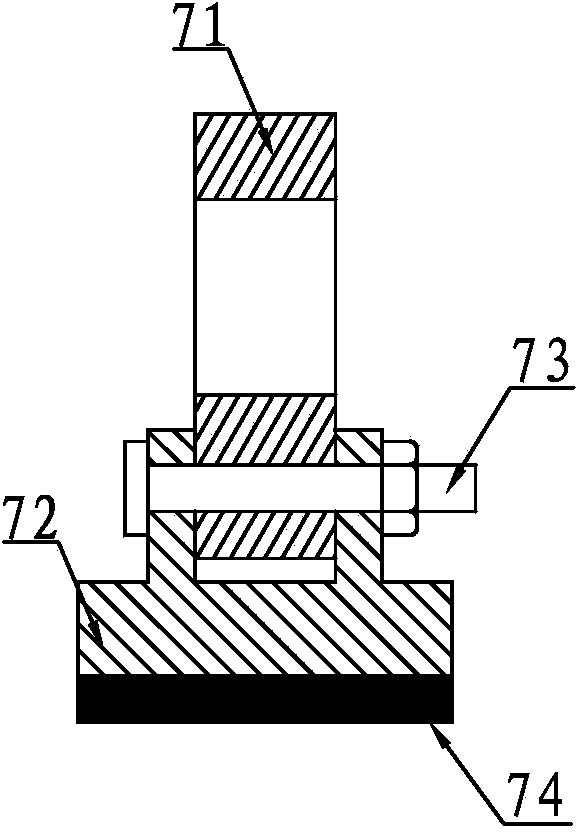

[0020] A kind of ingot turning fixture for polycrystalline silicon ingot turning over, such as Figure 1~3 Shown: including balance suspender 1, side clamping arm 2, side pressure adjusting screw 3, side clamping block 4, clamping block revolving pin 5, arm revolving pin 6, top anti-damage block 7 and sling 8, in balance The bottom of the two ends of the boom 1 is provided with a rotation notch 11 cooperating with the arm turning pin 6, and the two ends of the balance boom 1 are respectively fitted with side clamping arms 2, and the arm turning pin 6 is fixedly mounted on the side clamping arm 2. and corresponding to the rotation notches 11 at both ends of the balance suspender 1, the side pressure adjusting screw 3 is screwed on the upper end surface of the side clamping arm 2, and the lower end of the side pressure adjusting screw 3 is in contact with the upper end surface of the balance suspender 1. Correspondingly, the side clamping block 4 is composed of a rotating ear bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com