Method for producing 75Cr1 hot-rolled sheet steel

A technology of hot-rolled steel sheet and production method, applied in metal rolling, temperature control and other directions, can solve the specific solution method that does not mention 75Cr1 preparation technology and method, does not mention key technical problems, does not mention alloy tool steel technical and method issues, to achieve the effect of high pulling speed, moderate viscosity bulk density and high carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

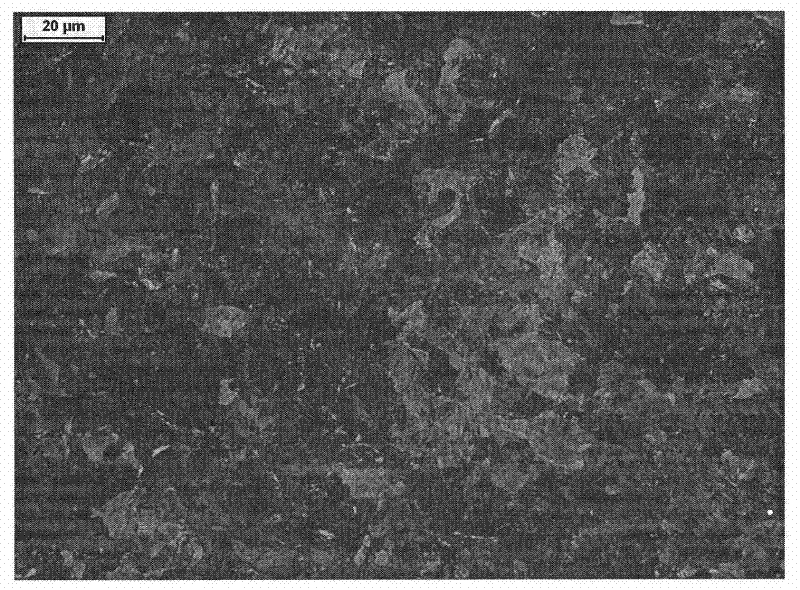

Embodiment 1

[0030] The method for producing 75Cr1 hot-rolled steel plates based on the thin slab continuous casting and rolling process described in this embodiment, the process flow: 150t ultra-high power electric furnace smelting, 150t ladle furnace refining, thin slab continuous casting, soaking, high pressure water descaling, hot Continuous rolling, laminar cooling, coiling.

[0031] The chemical composition weight percentage ratio (wt%) of the molten steel after the alloying treatment in the refining process is: C0.70, Si0.20, Mn0.60, P0.010, S0.004, Cr0.30, V0.02, The rest is Fe and unavoidable impurities.

[0032] Process parameters: billet entering furnace temperature T 入 is 908°C, the superheat of molten steel T 过 31°C, finishing temperature T 终 855°C, coiling temperature T 卷 560℃, continuous casting casting speed S 拉 3.6m / min, continuous casting liquid core depression 3mm, slab thickness 67mm.

[0033] The physical and chemical performance indicators of mold flux: the melt...

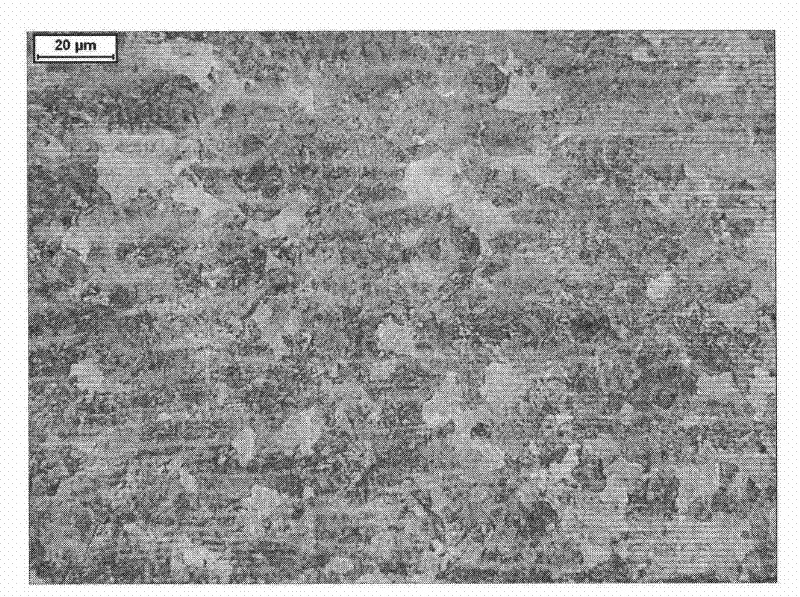

Embodiment 2

[0038] The method for producing 75Cr1 hot-rolled steel plates based on the thin slab continuous casting and rolling process described in this embodiment, the process flow: 150t ultra-high power electric furnace smelting, 150t ladle furnace refining, thin slab continuous casting, soaking, high pressure water descaling, hot Continuous rolling, laminar cooling, coiling.

[0039] The chemical composition weight percentage ratio (wt%) of the molten steel after the alloying treatment in the refining process is: C0.80, Si0.45, Mn0.90, P0.023, S0.023, Cr0.60, V0.08, The rest is Fe and unavoidable impurities.

[0040] Process parameters: billet entering furnace temperature T 入 is 980°C, the superheat of molten steel T 过 44°C, finishing temperature T 终 945°C, coiling temperature T 卷 630℃, continuous casting casting speed S 拉 It is 5.4m / min, the continuous casting liquid core is pressed down by 18mm, and the casting slab thickness is 52mm.

[0041] The physical and chemical perform...

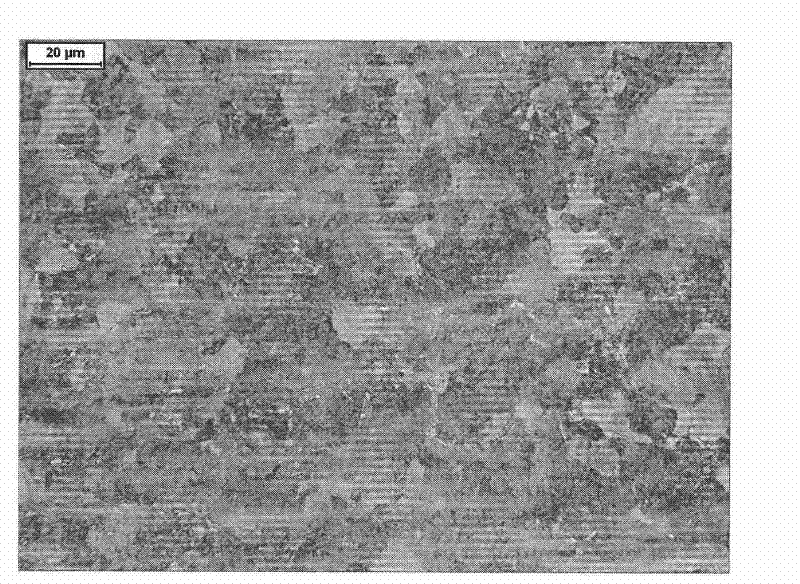

Embodiment 3

[0046] This embodiment is based on the method of thin slab continuous casting and rolling process to produce 75Cr1 hot-rolled steel plate. Process flow: 150t ultra-high power electric furnace smelting, 150t ladle furnace refining, thin slab continuous casting, soaking, high-pressure water descaling, hot continuous rolling , laminar cooling, coiling.

[0047] The chemical composition weight percentage ratio (wt%) of the molten steel after the alloying treatment in the refining process is: C0.75, Si0.40, Mn0.80, P0.010, S0.009, Cr0.40, V0.04, The rest is Fe and unavoidable impurities.

[0048] Process parameters: billet entering furnace temperature T 入 is 950°C, the superheat of molten steel T 过 39°C, finishing temperature T 终 880°C, coiling temperature T 卷 623°C, casting speed S 拉 4.3m / min, continuous casting liquid core reduction 6mm, slab thickness 64mm.

[0049] The physical and chemical performance indicators of mold flux: the melting point is 993°C, the basicity is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com