Self-compacting concrete and preparation method thereof

A technology for self-compacting concrete and cement, applied in the field of self-compacting concrete and its preparation, can solve the problems affecting the strength of self-compacting concrete, inconsistency in internal and external temperature difference, and difficult to disperse, etc., so as to improve overall compaction performance, reduce internal and external temperature difference, and reduce cracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

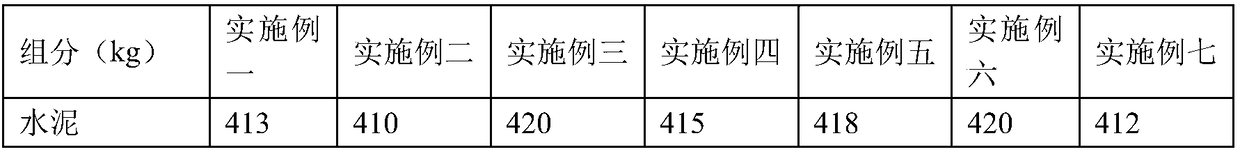

Embodiment 1

[0041] Embodiment one: a kind of preparation method of self-compacting concrete, comprises the steps:

[0042]Step 1. Heat 108kg of paraffin to a liquid state, inhale paraffin in 54kg of high-strength ceramsite under vacuum conditions, and after cooling down to room temperature, put the high-strength ceramsite with paraffin into emulsified asphalt, mix and package to obtain phase-change ceramsite;

[0043] Step 2. Stir 162kg of phase-change ceramsite and 10kg of slag powder evenly, then add 758kg of sand and 810kg of stones and mix for 5 minutes to form an aggregate mixture;

[0044] Step 3, 413kg cement, 53kg fly ash, 22kg slag powder, 32kg expansion agent were mixed and stirred for 3 minutes to obtain a slurry mixture;

[0045] Step 4, adding the slurry mixture prepared in step 3 to the aggregate mixture in step 2 and stirring in a forced mixer for 2 minutes to obtain a mixing material;

[0046] Step 5, 6.7kg polycarboxylate water reducer and 3.4kg binder are dissolved in w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com