Killed steel casting method

A casting method and technology for killing steel, applied in the field of metallurgical casting, can solve the problems of prolonged solidification time of steel ingots, difficult discharge of gas in steel, increase of inclusions, etc. The effect of surface cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

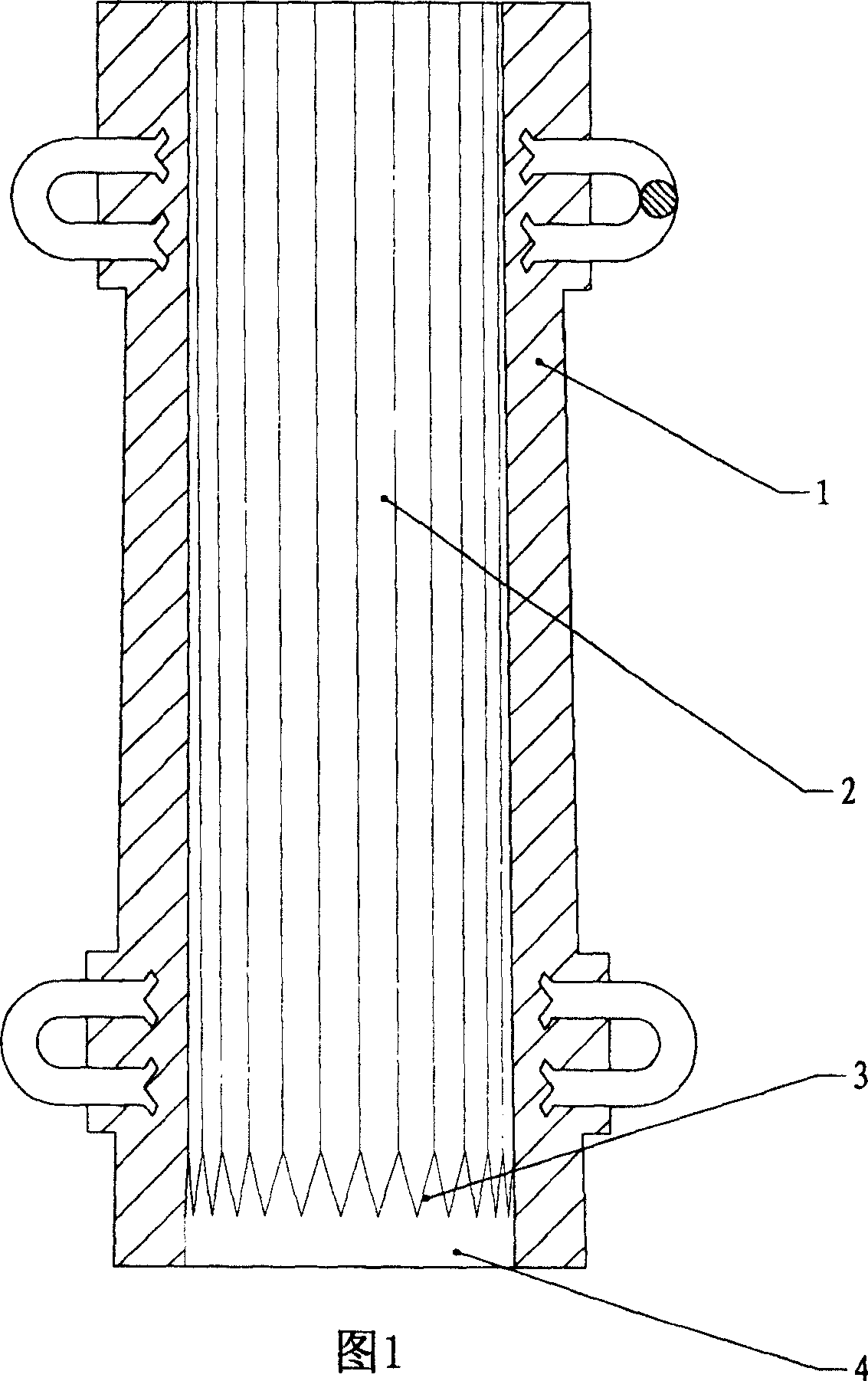

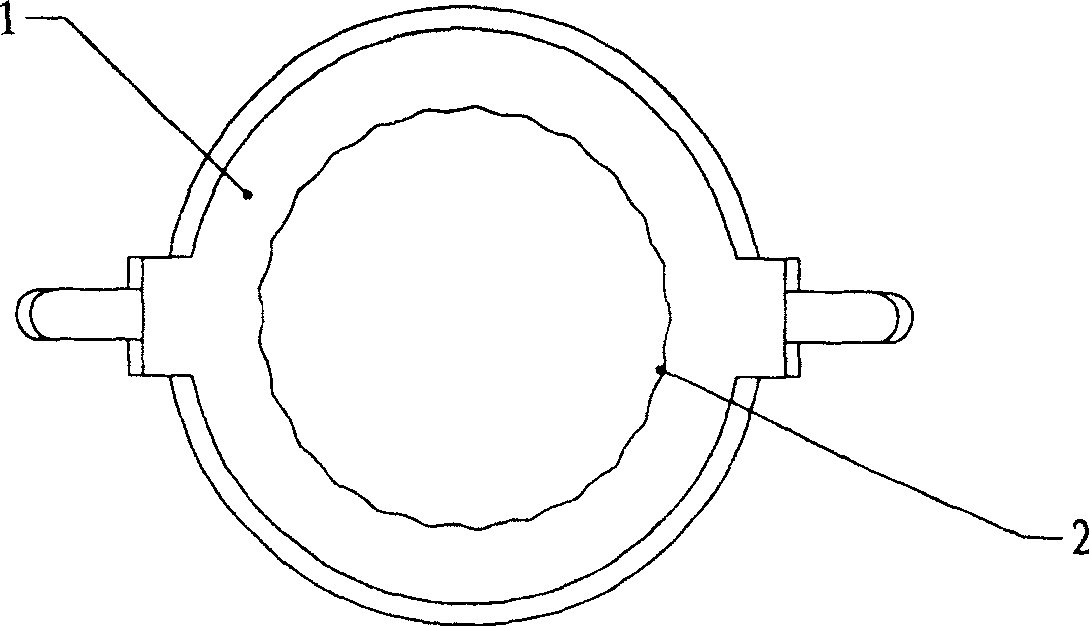

[0019] The casting method of killed steel of the present invention, with the steel ingot mold of wave section 2 as shown in Figure 1, adopts down casting method to cast 20 in 90t electric furnace # Φ580 / 4.0t large round corrugated steel ingot for pipe rolling with 25 sides of upper, lower, and lower.

[0020] 1. Process flow of steel ingots for casting and rolling pipes:

[0021] Electric furnace → DC (direct current) - ladle refining furnace LF → mold casting (car casting) → mold cooling → demoulding → steel ingot surface cleaning

[0022] 2. Quality control of molten steel:

[0023] 2.1 Before the end of refining, feed CaSi wire 0.4~0.6kg / t steel, and control the sulfur content of the steel out of the refining furnace below 0.025%;

[0024] 2.2 The temperature of the molten steel leaving the refining furnace is 1560-1580°C;

[0025] 3. Technical requirements for casting heat insulation board, mold slag and carbonized rice husk heat preservation agent:

[0026] 3.1 Techn...

Embodiment 2

[0073] The 90t electric furnace adopts the bottom casting method to cast 20G, Φ500 / 2.5t large round corrugated steel ingots for pipe rolling with upper, lower, and large 23 sides

[0074] 1. Process flow of steel ingots for casting and rolling pipes:

[0075] Electric furnace → DC (direct current) - ladle refining furnace LF → VD (vacuum treatment) → mold casting (vehicle casting) → mold cooling → demoulding → steel ingot surface cleaning

[0076] 2. Liquid steel quality control:

[0077] 2.1 The furnace body is abnormal and the second furnace before the new furnace body cannot smelt Benxi Steel;

[0078] 2.2 New ladles and new ingot molds shall not be used;

[0079] 2.3 The casting system must be clean and dry, and cast with Ar gas protection;

[0080] 2.4 Feed CaSi wire 0.4~0.6kg / t steel before the end of refining, control the sulfur out of the refining furnace below 0.025%, and the temperature of molten steel out of the VD furnace is 1565~1580℃;

example 1

[0082] 4. Preparation before casting:

[0083] 4.1 Select the steel ingot mold with good inner surface quality, do a good job of brushing the mold, and use high-quality refractory materials for the casting system.

[0084] 4.2 It is strictly forbidden to use cold molds and hot molds, and the temperature of the ingot mold during casting should not exceed 60°C;

[0085] 4.3 See Table 2 for the height of the center injection pipe used

[0086] 4.3 Use the ingot mold every time to clean the residual steel and sticky slag on the inner wall, and then blow it with compressed air;

[0087] 4.4 It is forbidden to water the ingot mold for cooling.

[0088] 4.5 See Example 1 for others.

[0089] 5. Casting operation:

[0090] 5.1 Casting superheat: 60~90℃;

[0091] 5.2 Pouring speed: see Table 2

[0092] 5.3 The steel pouring operator should determine the casting speed according to the temperature of molten steel and the season, and the liquid steel level should rise steadily durin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com