Alumina hollow ball brick and preparation method thereof

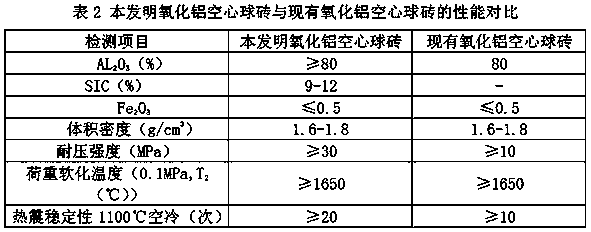

A technology of alumina hollow balls and hollow ball bricks, which is applied in the field of refractory materials, can solve the problems of affecting service life, poor thermal shock stability, and low strength, so as to save fuel consumption, improve thermal shock performance and strength, and improve thermal shock The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

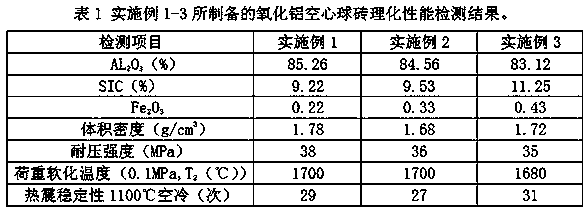

Embodiment 1

[0019] Embodiment 1: The alumina hollow ball brick of this embodiment is made of the following raw materials in parts by weight: 40 parts of alumina hollow balls, 15 parts of white corundum fine powder, 7 parts of silicon carbide, 14 parts of alumina fine powder, blue 3 parts of spar powder, 3 parts of sillimanite powder, 5 parts of clay, 10 parts of binder

[0020] Among them, the particle size of alumina hollow spheres is ≤4mm, the particle size of white corundum fine powder is ≤150 mesh, the particle size of silicon carbide is ≤200 mesh, the particle size of alumina fine powder is ≤500 mesh, and the particle size of kyanite fine powder is ≤500 mesh , the particle size of sillimanite powder is ≤500 mesh, and the particle size of clay is ≤200 mesh.

[0021] The preparation method of the present embodiment comprises the following steps:

[0022] (1) Mix white corundum fine powder, alumina fine powder, kyanite fine powder, sillimanite fine powder and clay in a mixing device (s...

Embodiment 2

[0026] Embodiment 2: The alumina hollow ball brick of this embodiment is made of the following raw materials in parts by weight: 30 parts of alumina hollow balls, 20 parts of white corundum fine powder, 5 parts of silicon carbide, 16 parts of alumina fine powder, blue 2 parts of spar micropowder, 4 parts of sillimanite micropowder, 4 parts of clay, 12 parts of binder, and the binder is pulp. The particle size of each raw material is the same as in Example 1.

[0027] The preparation method of the present embodiment comprises the following steps:

[0028] (1) Mix white corundum fine powder, alumina fine powder, kyanite fine powder, sillimanite fine powder and clay in a mixing device (spiral mixer) to obtain a mixed powder for later use;

[0029] (2) Mix alumina hollow spheres, silicon carbide and mixed powder in a mixing device (star mixer) for 4 minutes, then add binder and mix for 8 minutes to form mud;

[0030] (3) Vibrating the mud in the forming equipment to form bricks;...

Embodiment 3

[0032] Embodiment 3: The alumina hollow ball brick of this embodiment is made of the following raw materials in parts by weight: 50 parts of alumina hollow balls, 8 parts of white corundum fine powder, 10 parts of silicon carbide, 8 parts of alumina fine powder, blue 4 parts of spar micropowder, 2 parts of sillimanite micropowder, 7 parts of clay, and 8 parts of binder. The binder is pulp and aluminum sulfate, and the mass ratio of pulp and aluminum sulfate is 1:1.

[0033] The preparation method of the present embodiment comprises the following steps:

[0034] (1) Mix white corundum fine powder, alumina fine powder, kyanite fine powder, sillimanite fine powder and clay in a mixing device (spiral mixer) to obtain a mixed powder for later use;

[0035] (2) Mix alumina hollow spheres, silicon carbide and mixed powder in a mixing device (star mixer) for 3 minutes, then add binder and mix for 10 minutes to form mud;

[0036] (3) Vibrating the mud in the forming equipment to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com