High-activity steel slag micro-powder preparation system

A steel slag powder and preparation system technology, applied in lighting and heating equipment, grain processing, dryers, etc., to achieve the effects of eliminating hidden dangers in production safety, improving combustion rate, and reducing RO phase content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

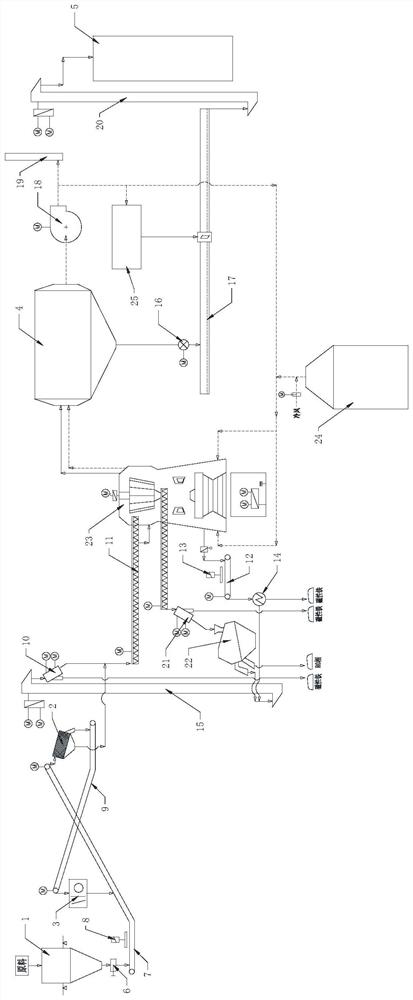

[0059] The high-activity steel slag powder preparation system includes a raw material warehouse, a traveling biomass combustion furnace, a screening device, a crushing device, a vertical mill grinding device, a dust collection device, an activator preparation device, and a finished product warehouse. The materials in the raw material warehouse are conveyed The device A is transported to the screening device, and the unqualified materials of the screening device are transported to the crushing device through the conveying device B, and the discharge port of the crushing device is connected to the conveying device A, and the qualified materials of the screening device pass through The reamer is transported into the mill and transported to the vertical mill grinding device. The powder separator is installed in the vertical mill grinding device. The qualified finished products after sorting are collected by the dust collection device. The reamer is transported to the magnetic separ...

Embodiment 2

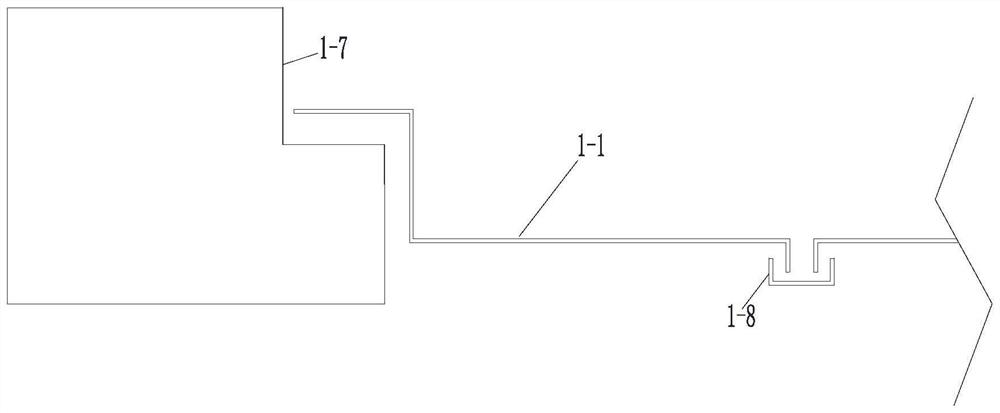

[0065] The advancing type biomass burning furnace includes a moving grate bed structure of the biomass burning furnace inside it, and the moving type grate bed structure includes a driving device and several traveling grate plates arranged in parallel, and the driving device drives the The traveling grate reciprocates along its central axis, and the traveling grate moves back in batches after moving to the slag outlet of the biomass combustion furnace, and the retreating traveling grate is separated by at least one traveling grate open.

[0066] When one of the rows moves backwards, because the ash is subjected to the pressure of the upper material, its own gravity and the forward thrust of its adjacent row units, the backward movement speed of the ash is only 20% of the forward speed, thus Realize the gradual advancement of ash and slag, and realize the effect of automatic slag removal.

[0067] Furthermore, it can also be considered in the present invention that the driving...

Embodiment 3

[0083] The traveling biomass burner uses biomass fuel.

[0084] The use of biomass combustion furnaces instead of coal-fired or gas-fired furnaces as the heat source for the steel slag grinding system reduces the amount of harmful gases such as nitrogen oxides caused by coal combustion during the preparation of steel slag fine powder, which is beneficial to environmental protection and reduces non-renewable gas such as coal combustion. Use of resources: Biomass fuel comes from a wide range of sources, and wood chips and rice husks can be used, which solves the difficult problem of traditional wood chips and rice husks, and reduces the fire risk of rice husks burned in farmers' cultivated land.

[0085] Further speaking, it can also be considered in the present invention that the biomass combustion furnace is fed by a conveying reamer, and a steady flow bin is provided at the feed inlet of the conveying reamer, and the blower A and the blower B are connected to the combustion fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com