Good manufacturing practice (GMP) workshop and design method of GMP workshop human logistics dual perpendicular through layout

A technology of vertical layout and human flow, applied in the direction of space heating and ventilation, heating method, mechanical equipment, etc., can solve the problems of personnel waste, repeated changing of clothes, etc., and achieve the goal of reducing production energy consumption, quantity, and clean changing area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

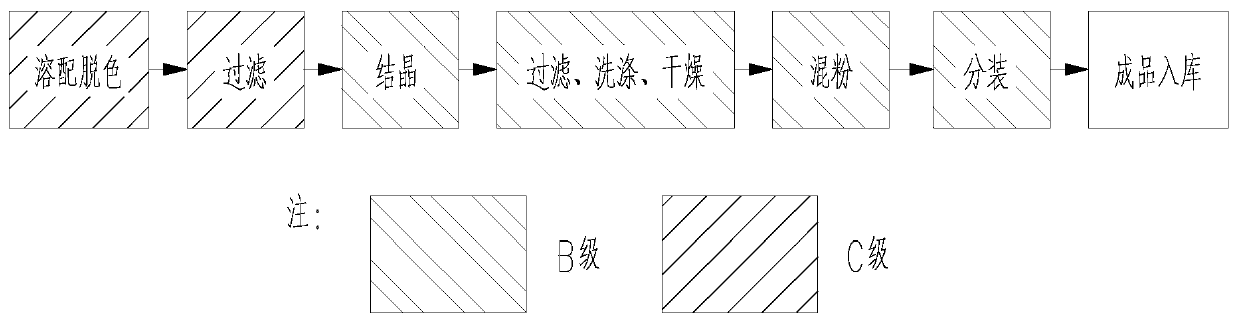

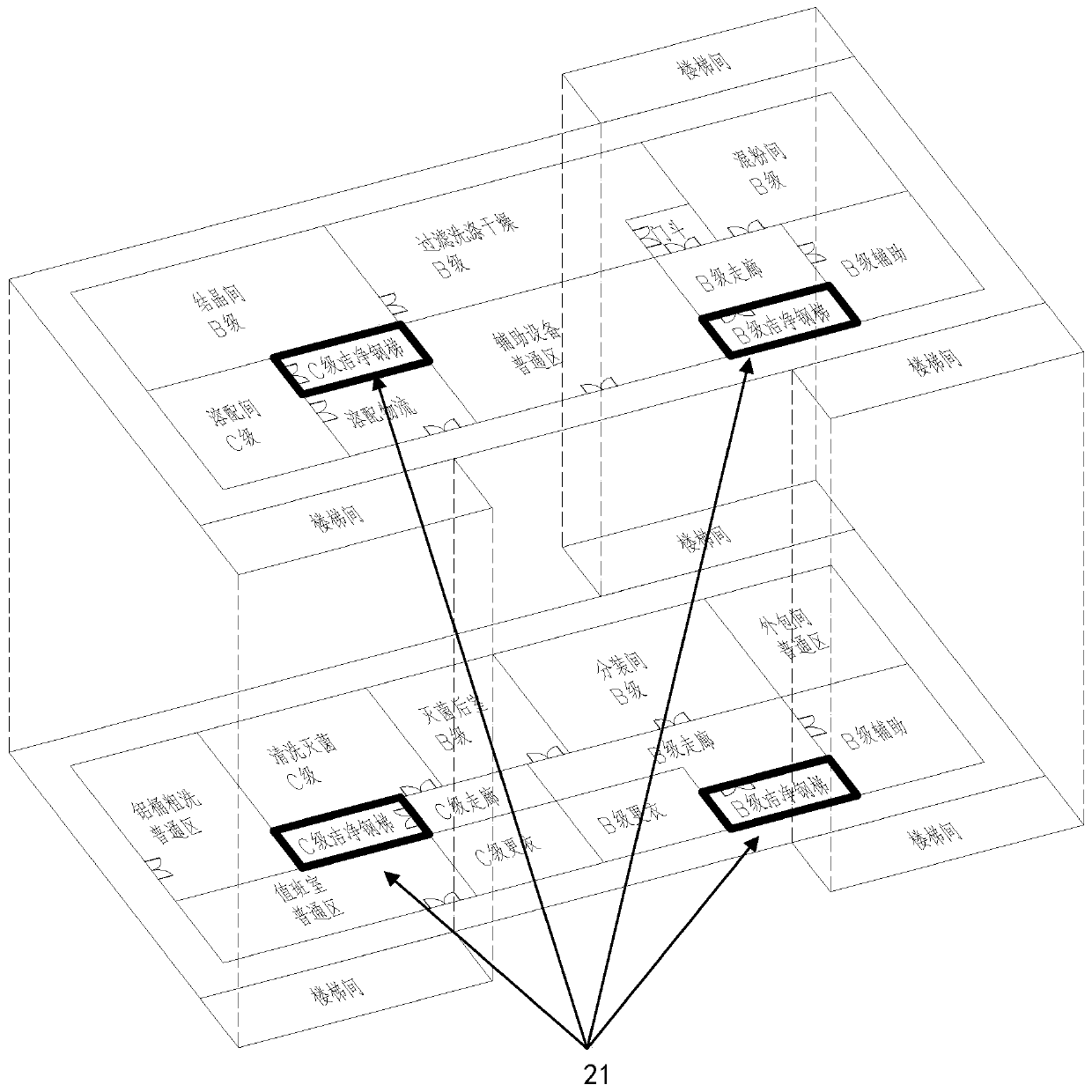

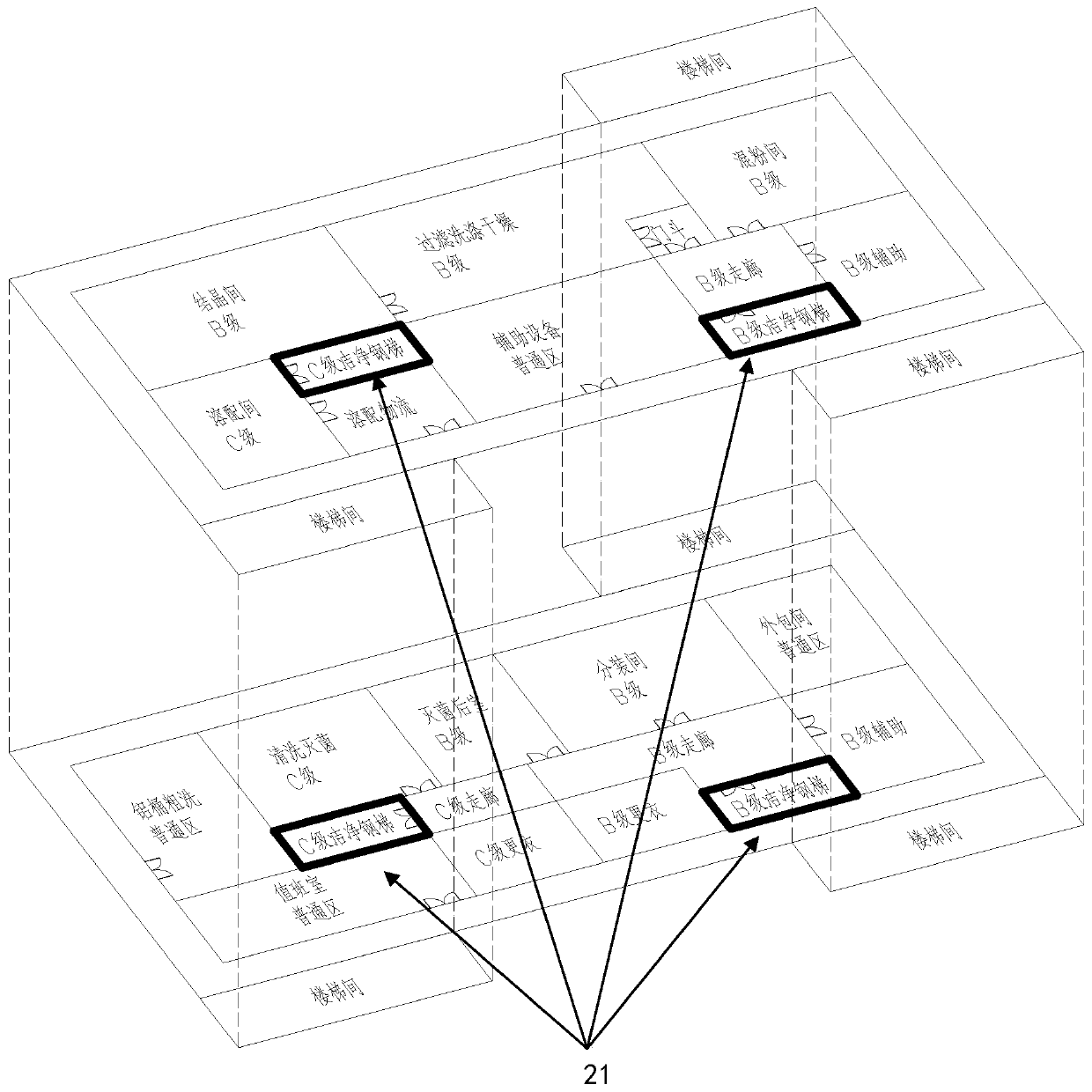

[0017] In order to solve the problem that the upper and lower clean areas of the GMP workshop production line with vertical logistics layout need to be operated by personnel, there is a need for personnel to go through the changing system when entering and leaving the clean area. The process causes problems such as waste of personnel or inconvenient operation. The present invention optimizes the design of the GMP workshop production line with the vertical distribution of logistics, and better solves this problem. On the basis of meeting the basic requirements of the GMP specification, it solves the problem that the personnel in the clean area can easily enter the upper and lower floors when the logistics of the GMP workshop is vertically arranged. This achievement can reduce the number of workers in the clean area, reduce unnecessary clean changing area, reduce production energy consumption, and has practical value in the design field of GMP workshops.

[0018] A design metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com