Energy-saving agent special for spindle motor of textile machine and preparation method thereof

A technology of spindle motor and energy-saving agent, applied in the directions of additives, petroleum industry, lubricating compositions, etc., to achieve the effect of good temperature resistance, good mechanical stability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

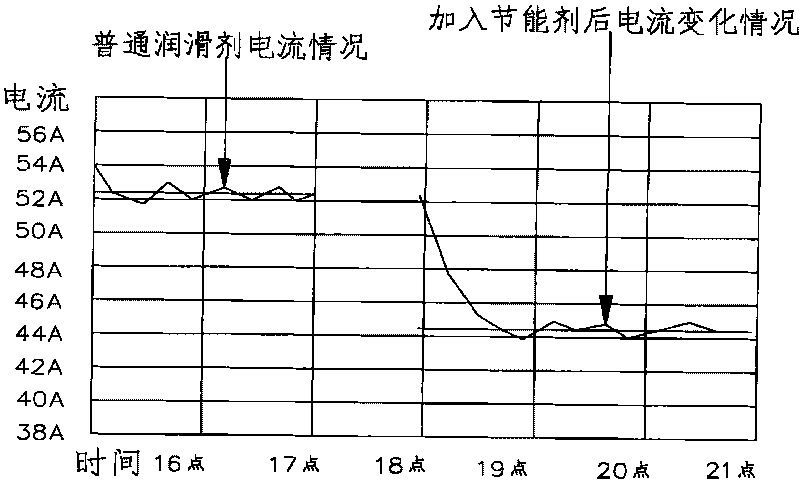

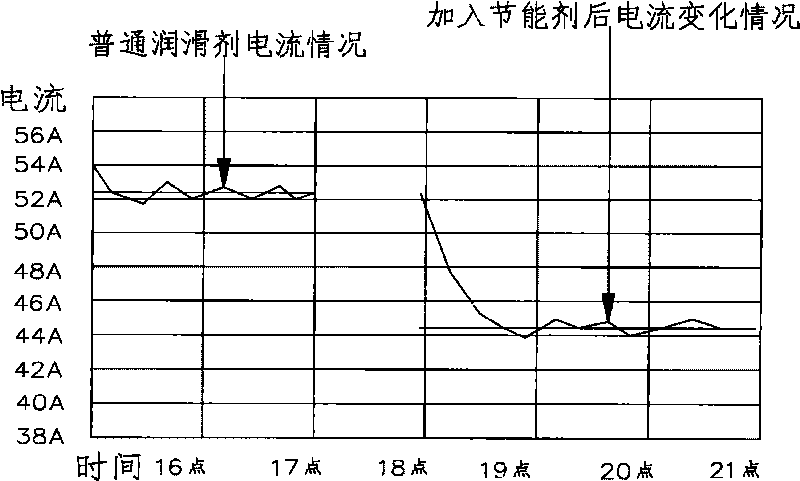

Image

Examples

Embodiment 1

[0029]Embodiment 1 A special energy-saving agent for the spindle motor of textile machinery, containing 0.8kg of nano-scale diamond powder (10-80nm in particle size), 950kg of 3# general-purpose lithium-based grease, silicon-containing alkylaryl polyether (S-2108, Guangzhou Shouzheng Chemical Technology Co., Ltd.) 1kg, RSB-607 (copper anti-discoloration agent, produced by Jiangxi Ruisibo Chemical Co., Ltd.) 8kg, polyetheramine detergent and dispersant (WFL-1000, purchased from Huisheng International Trade Co., Ltd.) 7kg, 10% polyvinyl alcohol 17-88 (polymerization degree 1700, alcoholysis degree 88%) 60kg.

[0030] The preparation method of the above-mentioned special energy-saving agent for the main shaft motor of textile machinery is as follows: Take 0.8kg of nano-diamond micropowder, 1kg of silicon-containing alkylaryl polyether and 600kg of 10% polyvinyl alcohol 17-88 solution, add it to a mixer, and adjust the temperature to 50°C , stir and disperse at a speed of 5000r / mi...

Embodiment 2

[0031] Embodiment 2 A special energy-saving agent for the spindle motor of textile machinery, containing 0.9kg of nano-scale diamond powder, 980kg of 3# general lithium base grease, 1.2kg of silicon-containing alkyl aryl polyether (LH-710), RSB-607 6kg, polyetheramine detergent dispersant 8kg, chitosan derivative solution 70kg.

[0032] The preparation method of the special energy-saving agent for the spindle motor of the above-mentioned spinning machine is as follows: take 0.9kg of nano-diamond micropowder, 1.2kg of silicon-containing alkylaryl polyether and 70kg of chitosan derivative solution, add to a mixer, adjust the temperature to 60°C, and Stir and disperse at a speed of 5500r / min for 2 to 3 hours and put it aside for later use; take 980kg of 3# general-purpose lithium-based grease and heat up at 80°C to make a solution, put it into a mixing tank, add 6kg of antioxidant RSB-607, polyetheramine to clean and disperse Add 8kg of the agent, stir at a speed of 70 rpm for 1 ...

Embodiment 3

[0034] Embodiment 3 A special energy-saving agent for the main shaft motor of textile machinery, containing 0.1kg of nano-scale diamond powder, 900kg of 3# general-purpose lithium-based grease, 0.5kg of silicon-containing alkylaryl polyether, 5kg of RSB-607, polyetheramine 5kg of detergent and dispersant, 20kg of chitosan derivative solution. Its preparation method is basically the same as embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com