Bearing vibration-reducing chemical milling agent and method for using same

A chemical grinding and bearing technology, applied in the field of bearing processing, can solve the problems of insufficient surface processing accuracy, single part grinding, rough surface morphology of bearing raceways, etc., to improve surface morphology, reduce noise, and reduce vibration. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

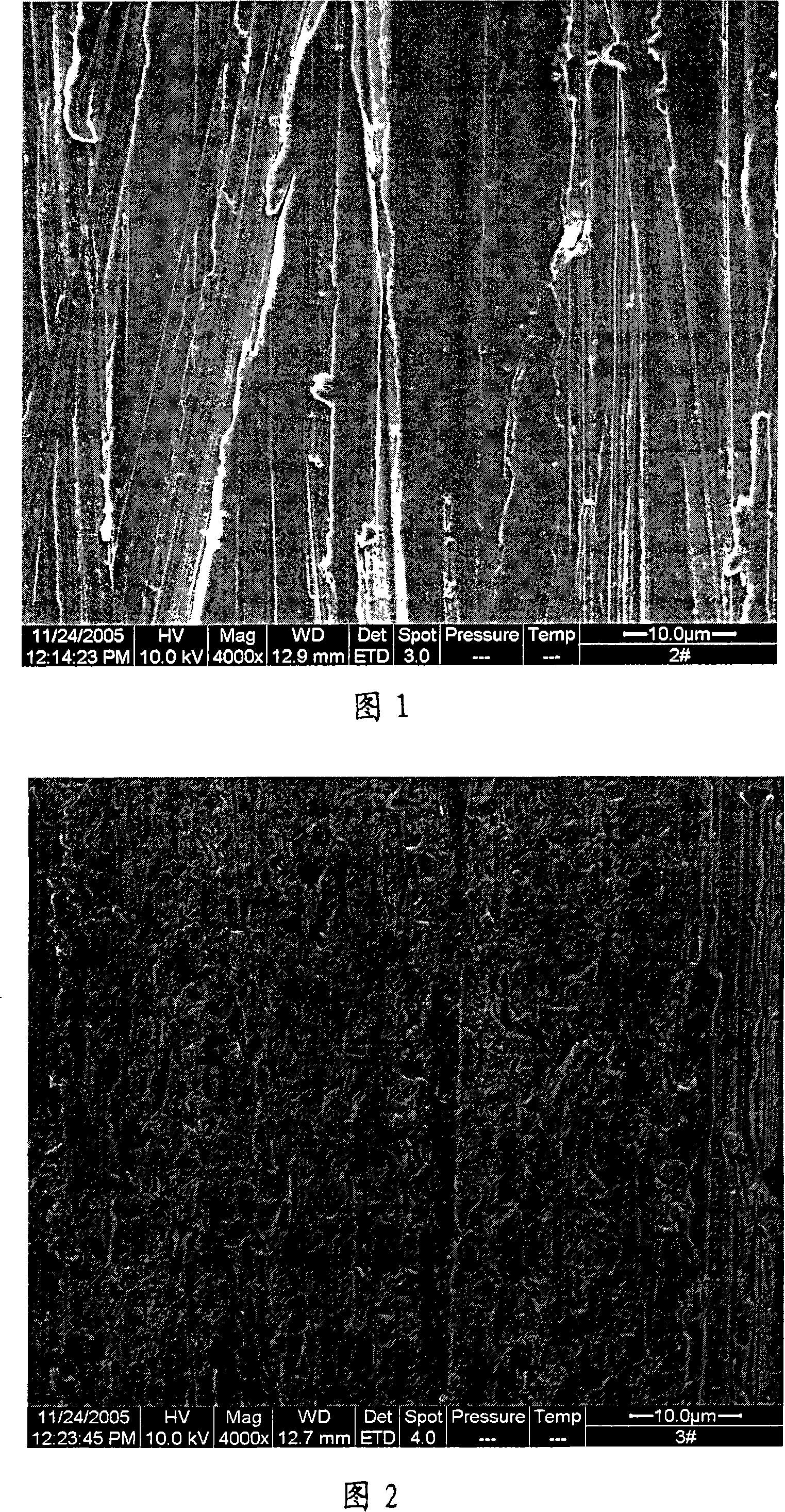

Image

Examples

Embodiment Construction

[0009] Bearing vibration reduction chemical abrasives mainly include abrasives, surfactants, anti-rust additives, and matrix media.

[0010] Abrasives account for 30-60%: including diamond 3-5%, chromium oxide 5-10%, silicon carbide 5-10%, boron carbide 4-10%, white corundum 3-5%, cerium oxide 5-10% %, zirconia 5-10%.

[0011] Surfactant 2-5%: including oxalic acid 1.5-3%, oleic acid 0.5-2%.

[0012] Anti-rust additive 3-5%: including triethanolamine 2-3%, sodium nitrite 1-2%;

[0013] The base medium is mineral oil, accounting for 30-65%.

[0014] When in use, adjust the proportion of abrasive formula reasonably according to the bearing material, model and surface appearance to be processed. Stir and mix the above-mentioned well-proportioned materials evenly, inject evenly into the surface of the bearing friction pair to be processed, grind at a speed of 900-1500 rpm for 2-5 minutes, and clean it ultrasonically with detergent. In the case of a small amount, it can also be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com